High-strength waterproof concrete

A technology for waterproof concrete and concrete, which is applied in the field of concrete to achieve the effects of good anti-seepage performance and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

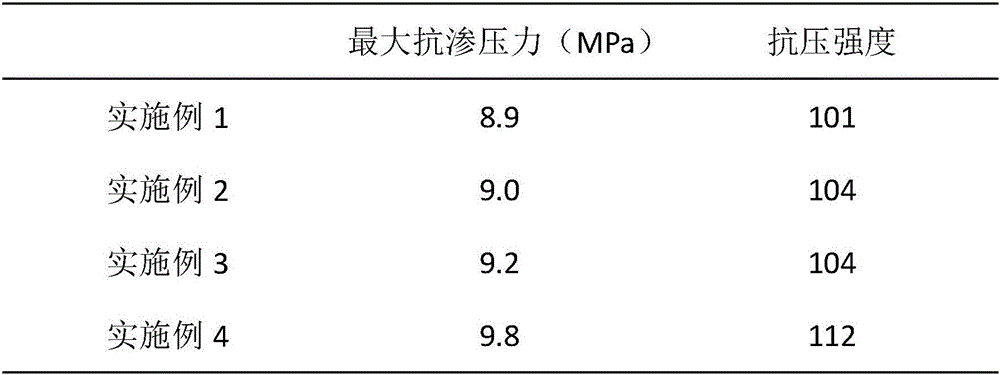

Examples

Embodiment 1

[0023] Raw material preparation: 120 parts of cement, 85 parts of coarse aggregate, 00 parts of fine aggregate, 25 parts of bentonite, 25 parts of asphalt powder, 5 parts of sodium alkylsulfonate, 3 parts of copper sulfate, 12 parts of basalt fiber, 8 parts of polypropylene fiber 3 parts of Grace fiber, 0.5 part of sodium perfluorooctane sulfonate, 0.2 part of coconut oil diethanolamide, 1 part of bisphenol A epoxy resin, 0.2 part of styrylphenol polyoxyethylene ether, 5 parts of ferric chloride 0.5 parts of phenyl salicylate, 5 parts of potassium aluminum sulfate, 0.2 parts of 1,6-hexamethylene diisocyanate, and appropriate amount of water.

[0024] The basalt fiber has a diameter of 0.15-0.20 mm and a length of 15-20 mm.

[0025] The polypropylene fiber has a diameter of 0.20-0.25mm and a length of 15-20mm.

[0026] The diameter of the Grace fiber is 0.20-0.35mm, and the length is 15-20mm.

[0027] (1) Mix cement, coarse aggregate, fine aggregate, bentonite and asphalt pow...

Embodiment 2

[0031] Raw material preparation: 110 parts of cement, 84 parts of coarse aggregate, 98 parts of fine aggregate, 24 parts of bentonite, 24 parts of asphalt powder, 4 parts of sodium alkylsulfonate, 3 parts of copper sulfate, 12 parts of basalt fiber, 8 parts of polypropylene fiber 3 parts of Grace fiber, 0.5 part of sodium perfluorooctane sulfonate, 0.2 part of coconut oil diethanolamide, 1 part of bisphenol A epoxy resin, 0.2 part of styrylphenol polyoxyethylene ether, 5 parts of ferric chloride 0.5 parts of phenyl salicylate, 5 parts of potassium aluminum sulfate, 0.2 parts of 1,6-hexamethylene diisocyanate, and appropriate amount of water.

[0032] The basalt fiber has a diameter of 0.15-0.20 mm and a length of 15-20 mm.

[0033] The polypropylene fiber has a diameter of 0.20-0.25mm and a length of 15-20mm.

[0034] The diameter of the Grace fiber is 0.20-0.35mm, and the length is 15-20mm.

[0035] (1) Mix cement, coarse aggregate, fine aggregate, bentonite and asphalt pow...

Embodiment 3

[0039] Raw material preparation: 105 parts of cement, 82 parts of coarse aggregate, 95 parts of fine aggregate, 22 parts of bentonite, 22 parts of asphalt powder, 2 parts of sodium alkylsulfonate, 2 parts of copper sulfate, 10 parts of basalt fiber, 5 parts of polypropylene fiber 2 parts of Grace fiber, 0.2 part of sodium perfluorooctane sulfonate, 0.1 part of coconut oil diethanolamide, 0.5 part of bisphenol A epoxy resin, 0.1 part of styrylphenol polyoxyethylene ether, 3 parts of ferric chloride 0.2 parts of phenyl salicylate, 2 parts of aluminum potassium sulfate, 0.1 part of 1,6-hexamethylene diisocyanate, and appropriate amount of water.

[0040] The basalt fiber has a diameter of 0.15-0.20 mm and a length of 15-20 mm.

[0041] The polypropylene fiber has a diameter of 0.20-0.25mm and a length of 15-20mm.

[0042] The diameter of the Grace fiber is 0.20-0.35mm, and the length is 15-20mm.

[0043] (1) Mix cement, coarse aggregate, fine aggregate, bentonite and asphalt po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com