Patents

Literature

59results about How to "Will not cause overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

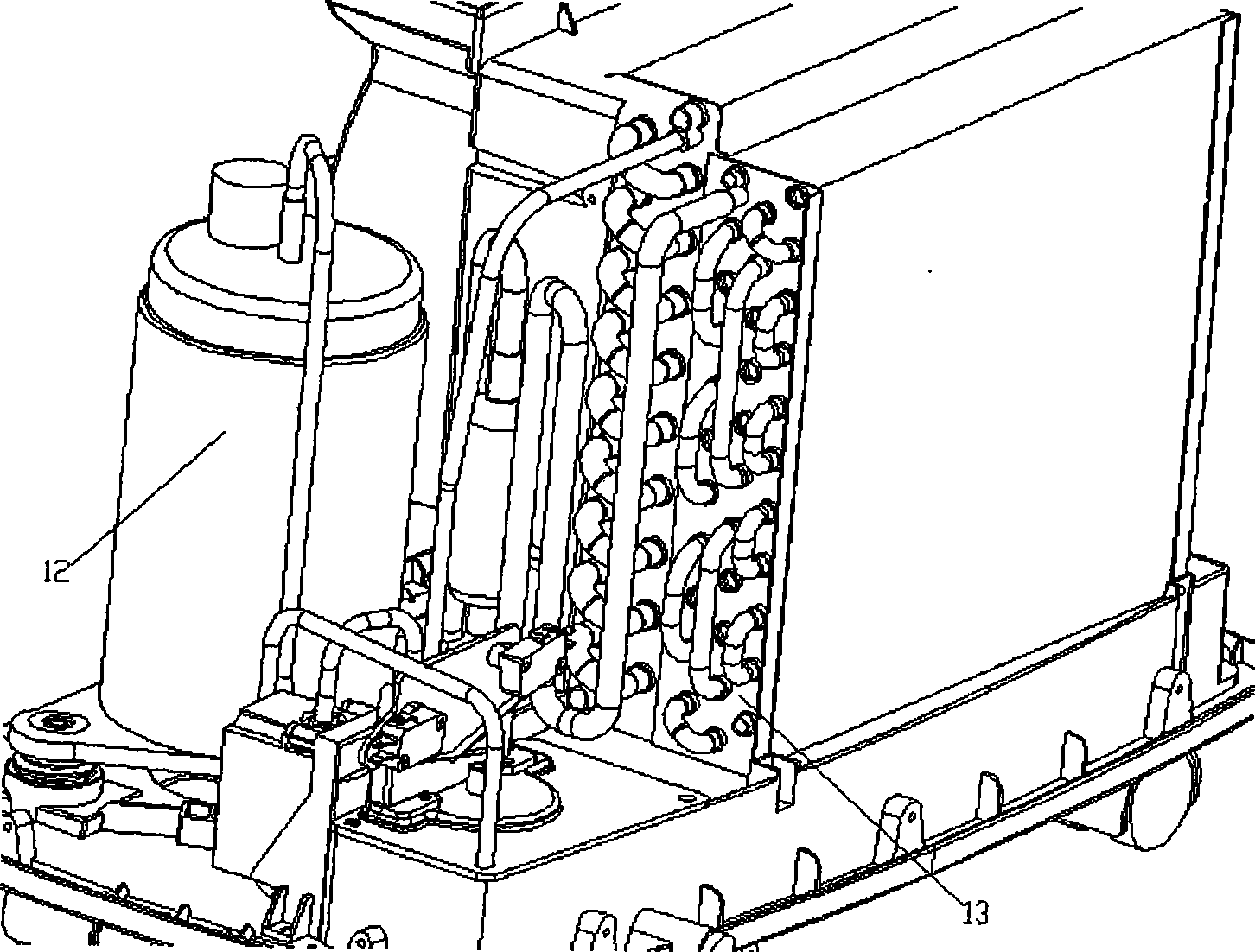

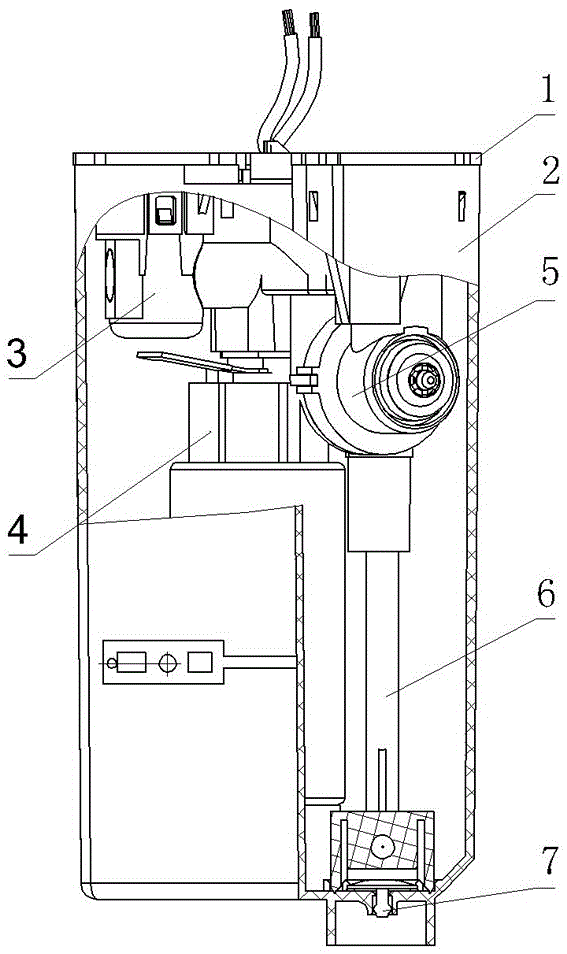

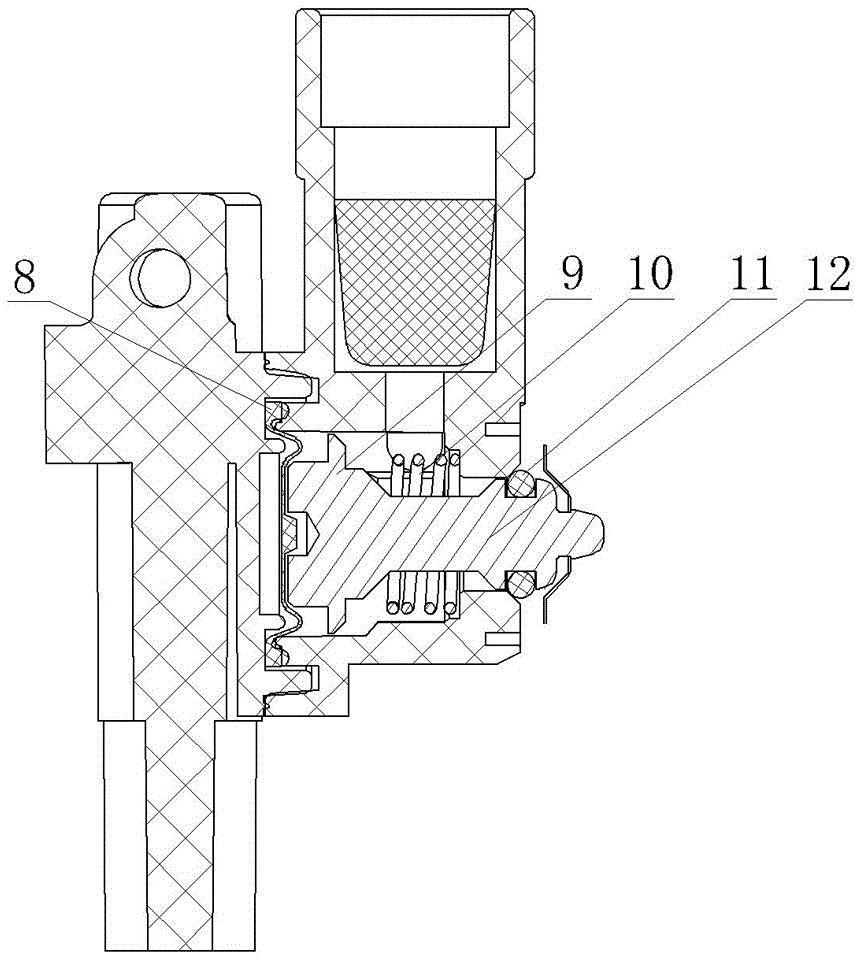

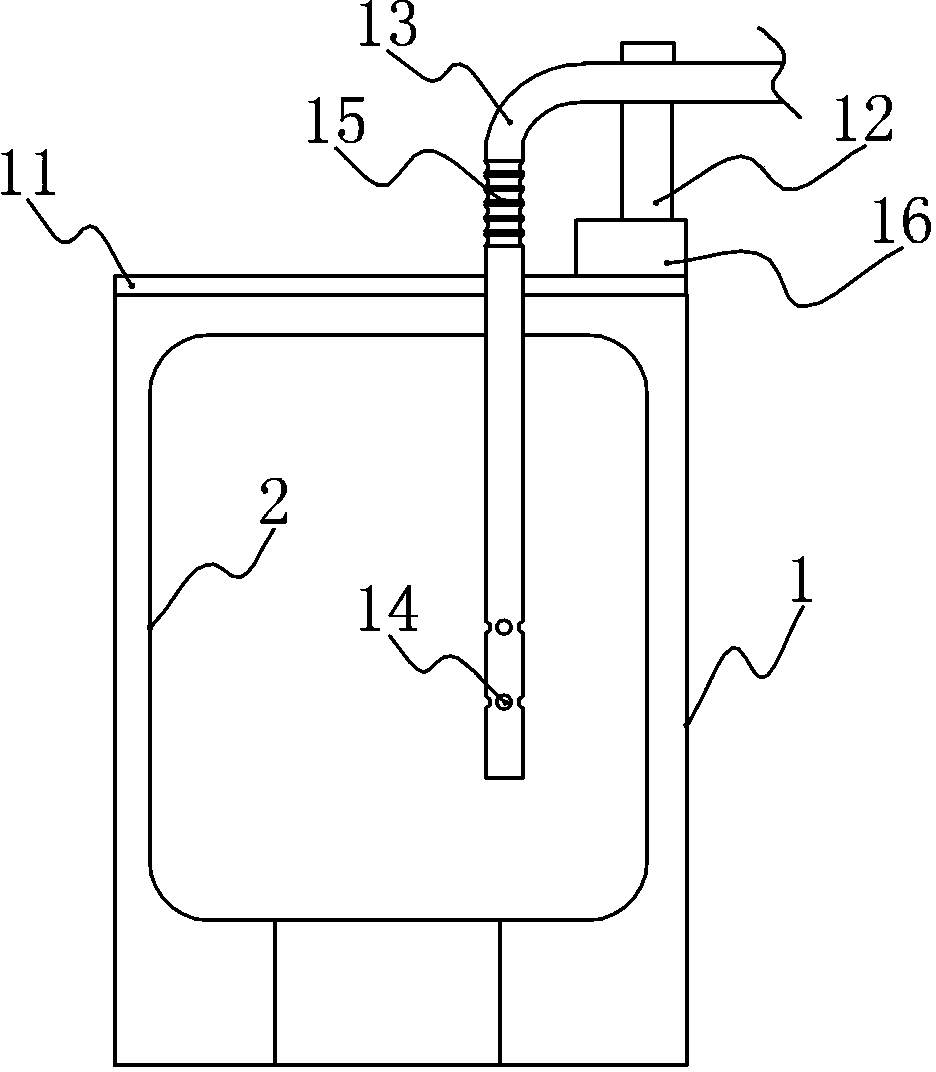

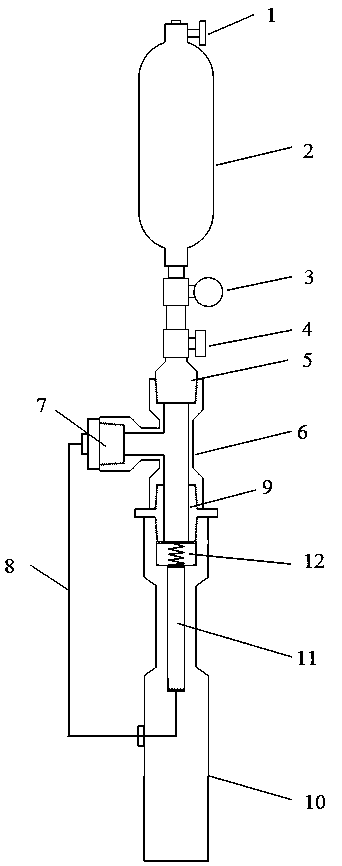

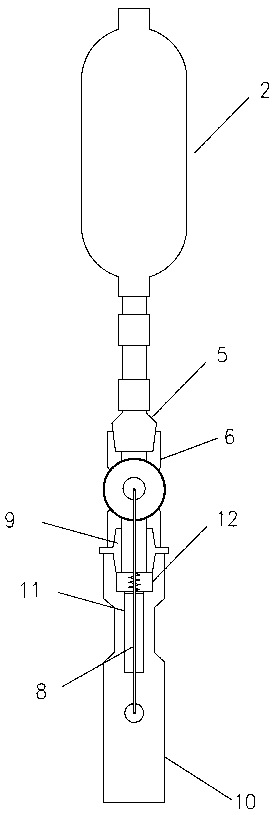

Automatic level-controlling draining dehumidifier and draining method thereof

InactiveCN101520214AReduce structure use spaceTimely exclusionCondensate preventionLighting and heating apparatusEngineeringDrainage tubes

An automatic level-controlling draining dehumidifier mainly comprises a water pump suction pipe, a water pump drainage pipe, an electromagnetic water pump, a water pump fixing cover, an inductive switch fixing part, a water fullness alarming switch, a pumping alarming switch, a drainage quick adapter assembly, a level measuring floater, a water-collecting tray, an osculum, an osculum plug, a compressor and a heat exchanger; the connection is as follows: one end of the water pump suction pipe is connected with the water-collecting tray and the other end is connected with the electromagnetic water pump; one end of the electromagnetic water pump is connected with the water pump suction pipe; the other end of the water pump drainage pipe is connected with the quick adapter assembly; the level measuring floater is arranged below the water pump fixing cover; and the water fullness alarming switch and the pumping alarming switch are fixed by the inductive switch fixing part. The draining method of the dehumidifier comprises the following steps: one electromagnetic water pump is arranged on the side surface of the water-collecting tray; when the dehumidifier is working, the condensed water is generated by the heat exchanger and falls into the water-collecting tray; the level measuring floater rises slowly under the effect of buoyancy with the increase of water quantity so as to measure the height of the water collected in the water-collecting tray; the floater firstly touches the pumping alarming switch with the rising of level and then the electromagnetic water pump starts to work; the quick adapter at the bottom of a chassis can be connected with a rubber drainage tube with length of about 5M; then the electromagnetic water pump drains the water inside the water-collecting tray out of the room through the water pump suction pipe and the water pump drainage pipe; if the floater touches the pumping alarming switch firstly but the electromagnetic water pump does not work.

Owner:NINGBO ERYE & ELECTRONICS

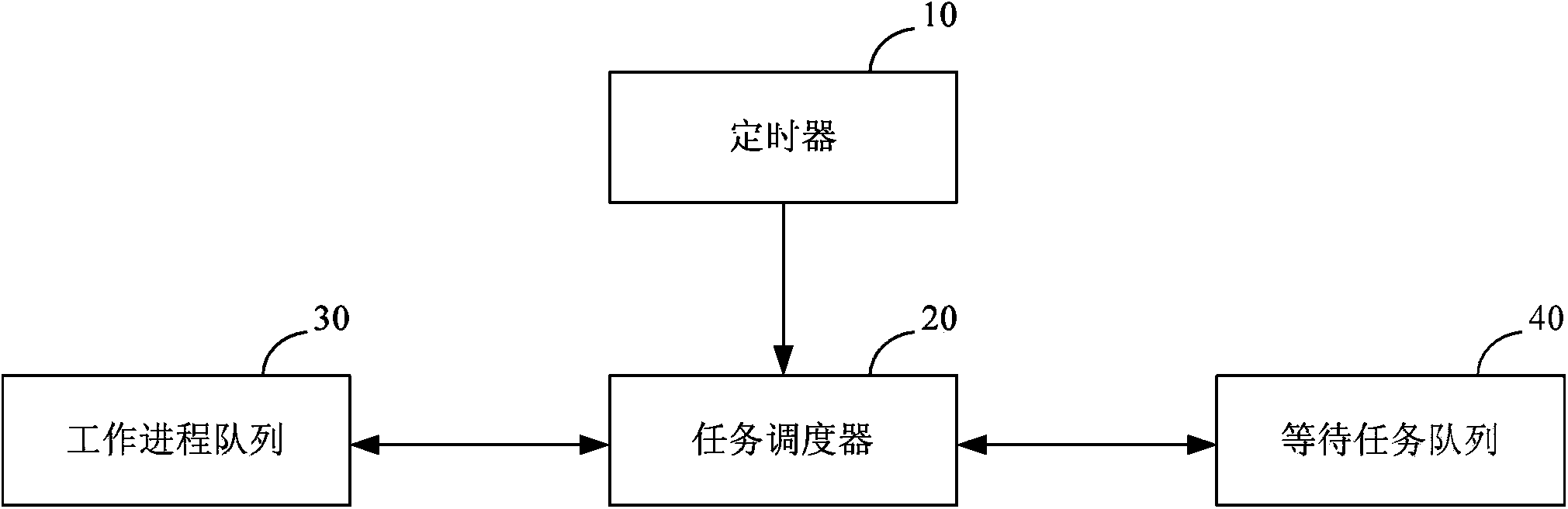

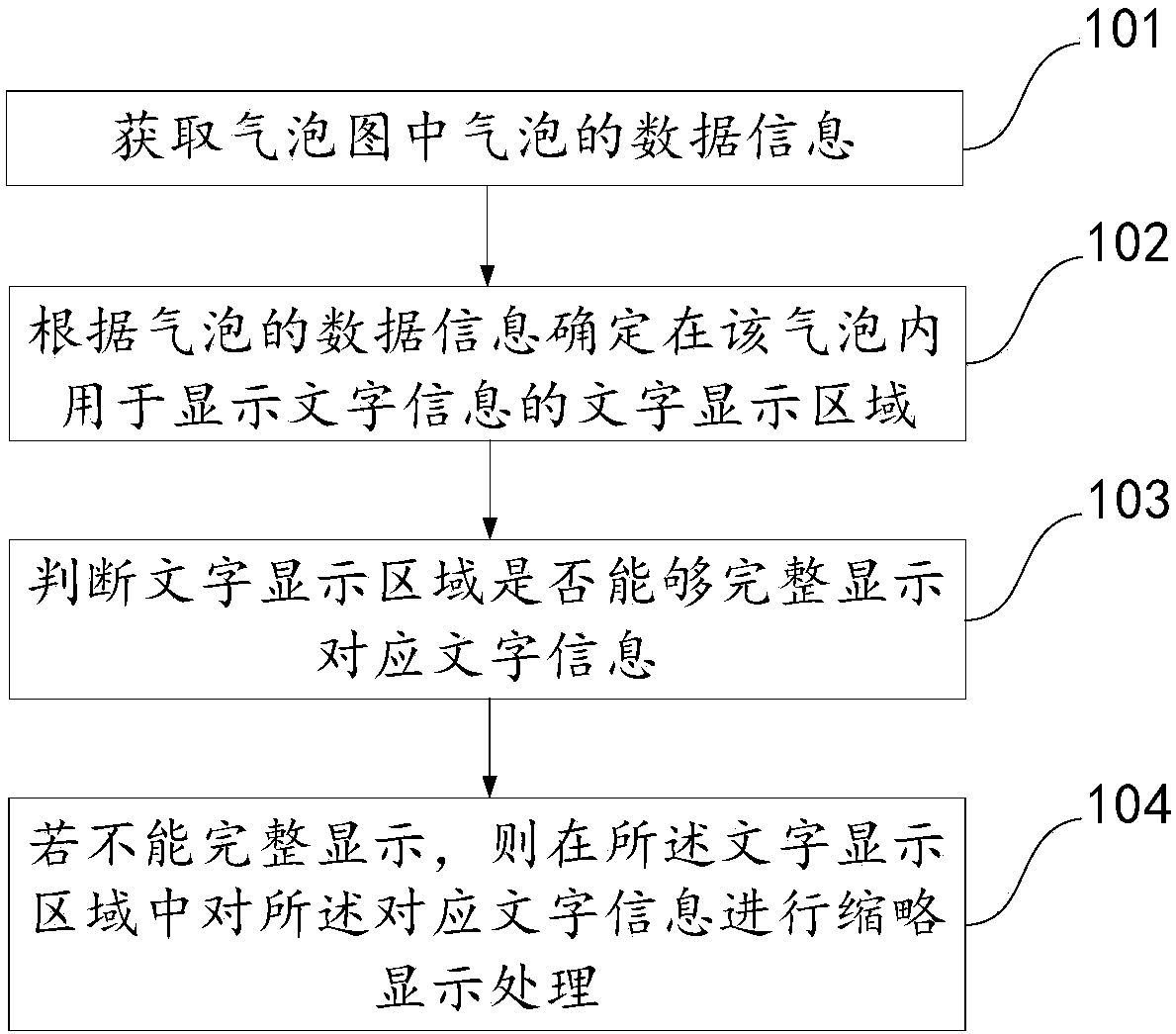

Bandwidth adjusting device and method

ActiveCN103533032AMake the most of your bandwidthImprove resource utilizationResource allocationTransmissionResource utilizationThe Internet

The invention discloses a bandwidth adjusting device and a bandwidth adjusting method and belongs to the field of internet techniques. The bandwidth adjusting device comprises a timer, a task scheduler and a working process queue, wherein the working process queue comprises a plurality of working process entries. Each working process executes a downloading task. The timer is used for informing the task scheduler at fixed time to obtain the current bandwidth of a server according to downloading tasks executed by the working processes which are contained by the working process queue. The task scheduler is used for obtaining the downloading speed of all downloading tasks which are being executed according to the notice of the timer, obtaining the current bandwidth of the server after all downloading speeds are summarized, and informing the working processes in the working process queue to limit the speed of the corresponding downloading speeds when the determined current bandwidth of the server reaches a preset bandwidth threshold. According to the bandwidth adjusting device and the bandwidth adjusting method, the resource utilization rate of the server can be improved.

Owner:BEIJING QIHOO TECH CO LTD

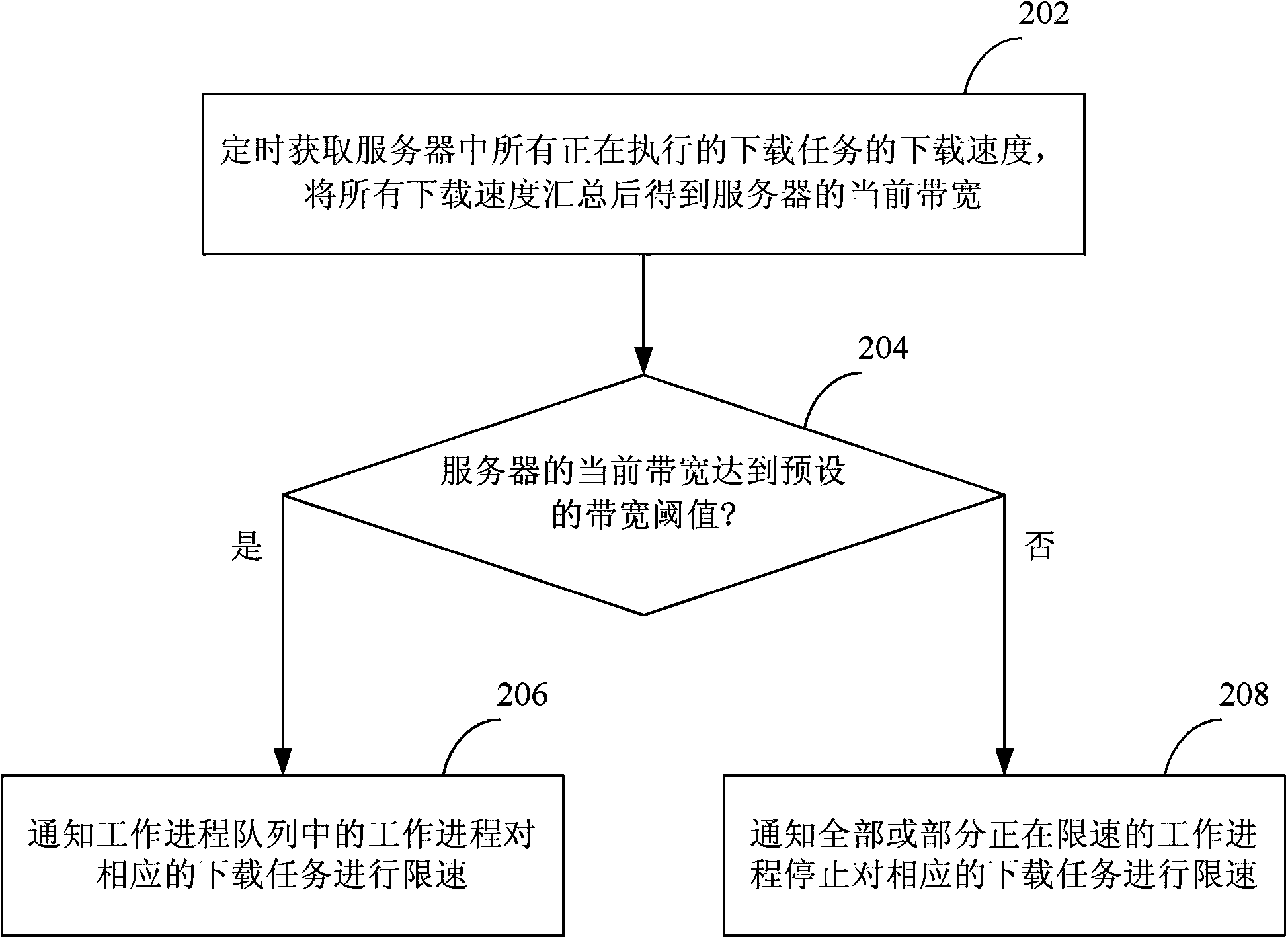

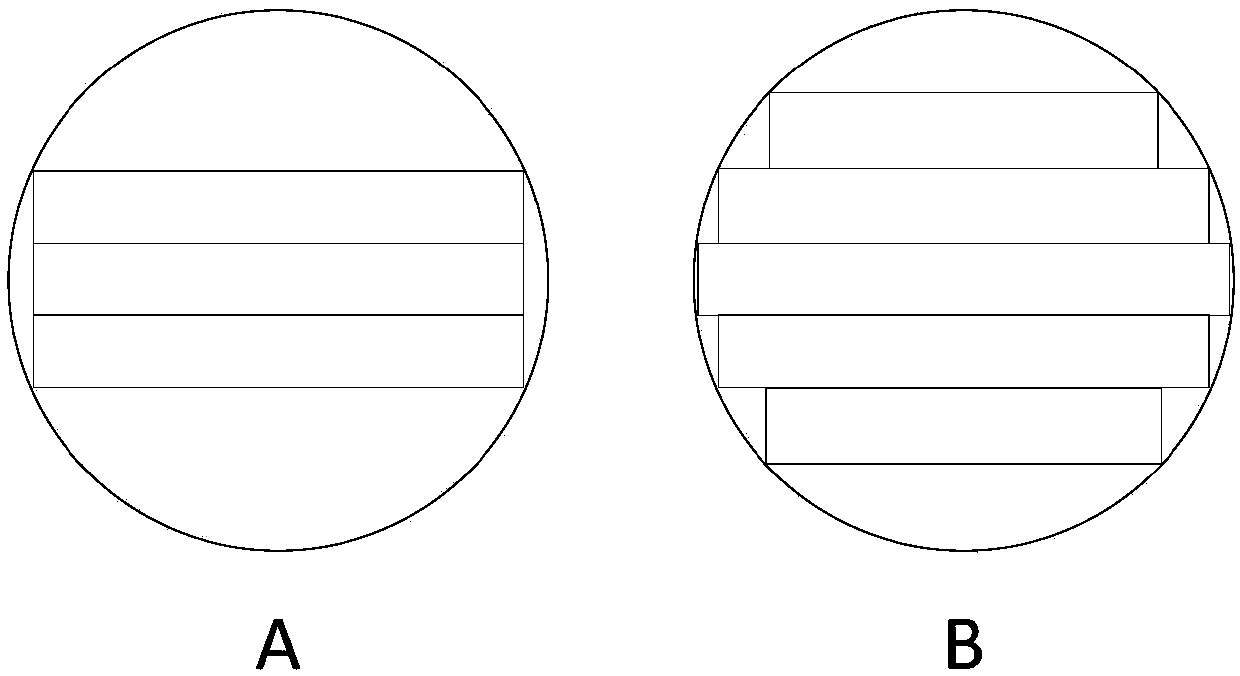

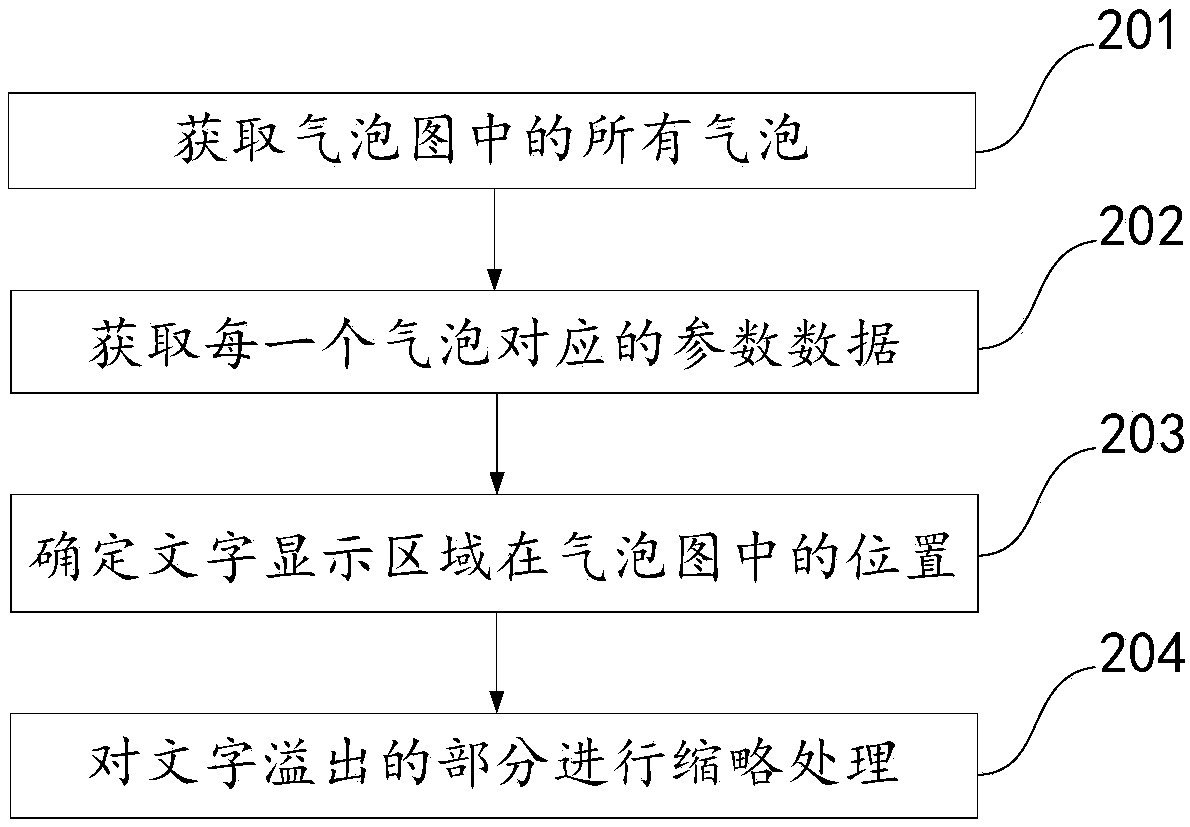

Bubble graph text display method and device

InactiveCN107945248ACorrespondence is clearImprove the overall display effectEditing/combining figures or textDisplay processingData information

The invention discloses a bubble graph text display method and device, which relate to the technical field of computer. The main purpose of the invention is to display the text corresponding to a bubble in a bubble graph in the bubble as many as possible, avoid information display confusion caused by overlapping of the texts corresponding to adjacent bubbles and improve the overall display effectof the bubble graph and the user experience in viewing the bubble graph. According to the main technical scheme of the invention, the method includes the following steps: obtaining data information ofa bubble in a bubble graph, wherein the data information includes the position and size of the bubble and corresponding text information; determining a text display area for displaying text information in the bubble according to the data information; determining whether the corresponding text information can be fully displayed in the text display area; and if the corresponding text information cannot be fully displayed, displaying the corresponding text information in the text display area in an abbreviated way. The method and the device are mainly used to optimize the texts in a bubble graph.

Owner:BEIJING GRIDSUM TECH CO LTD

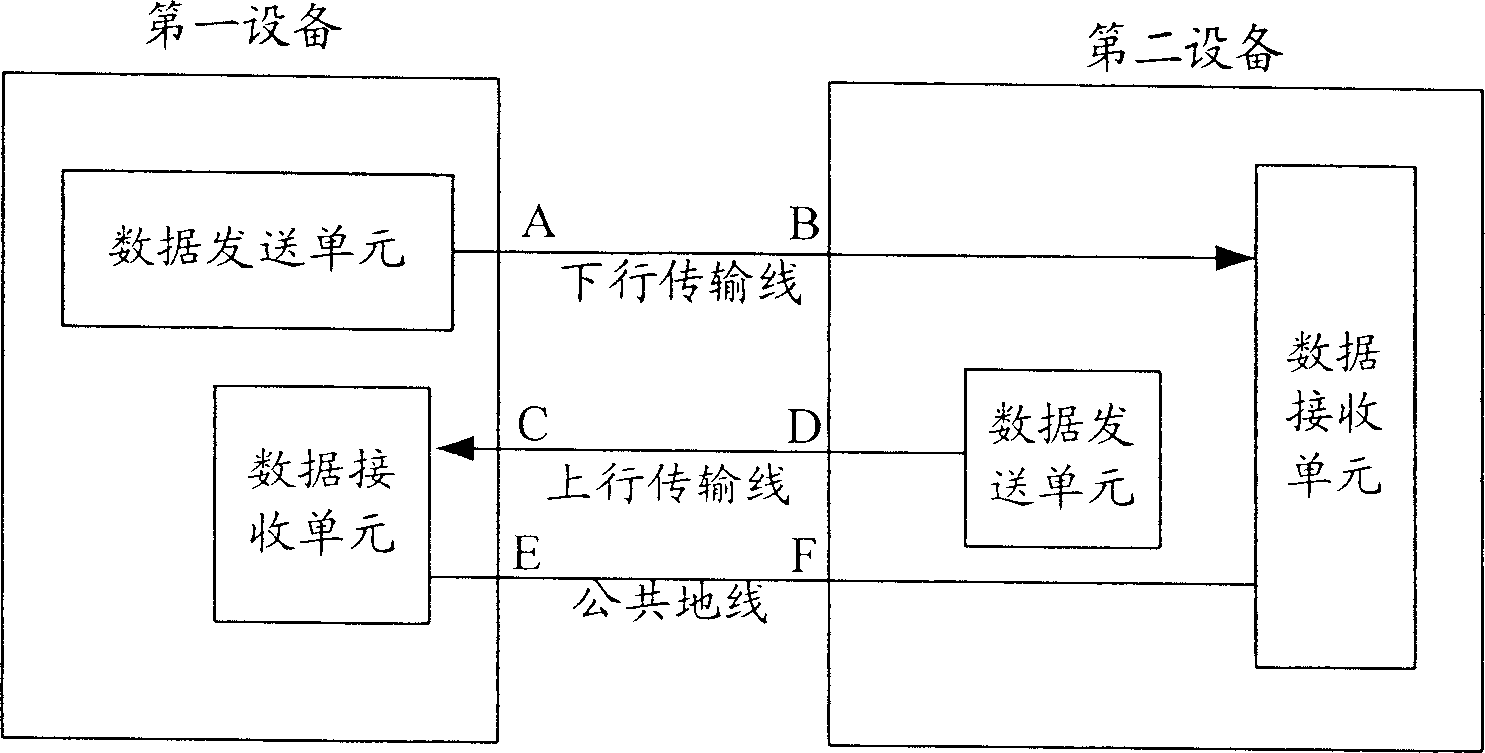

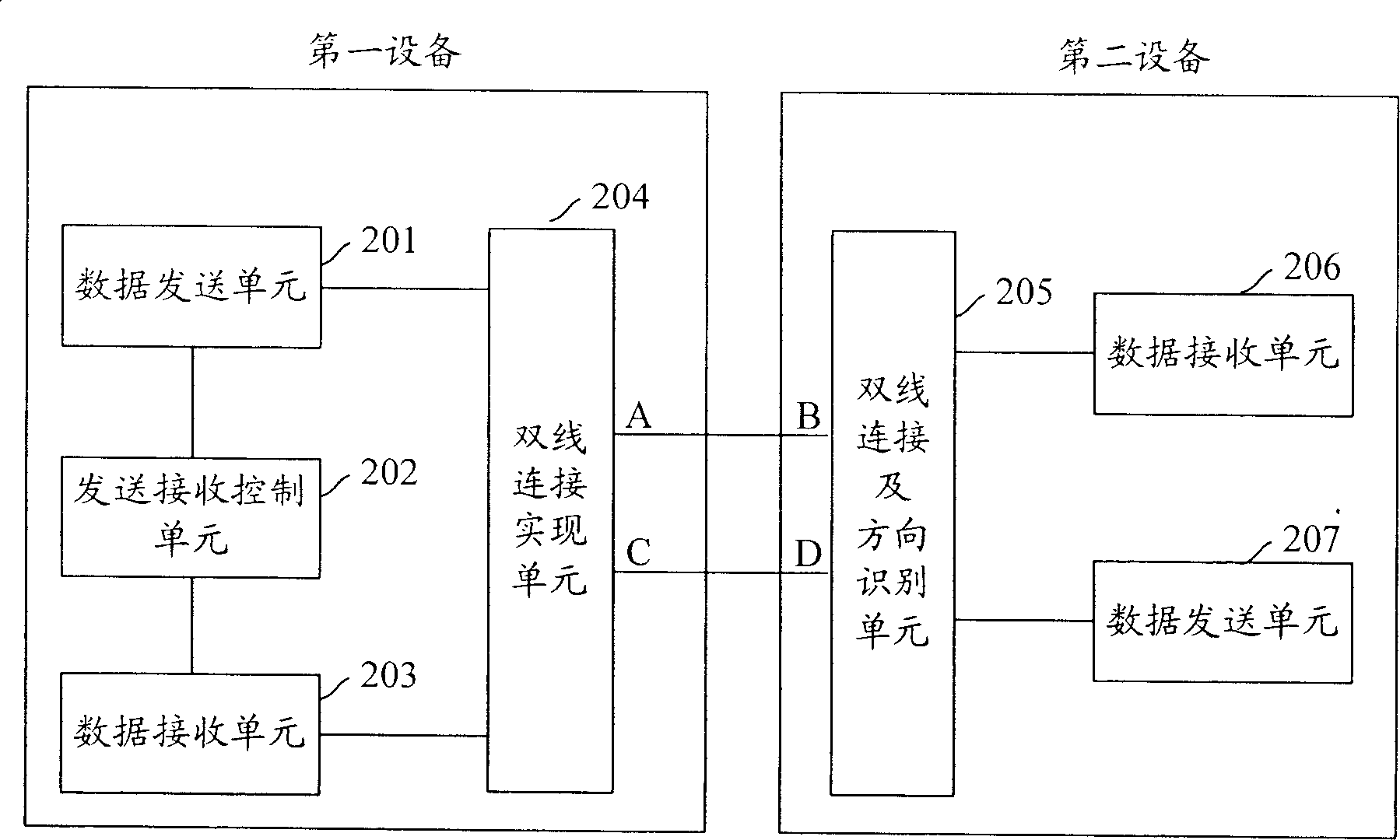

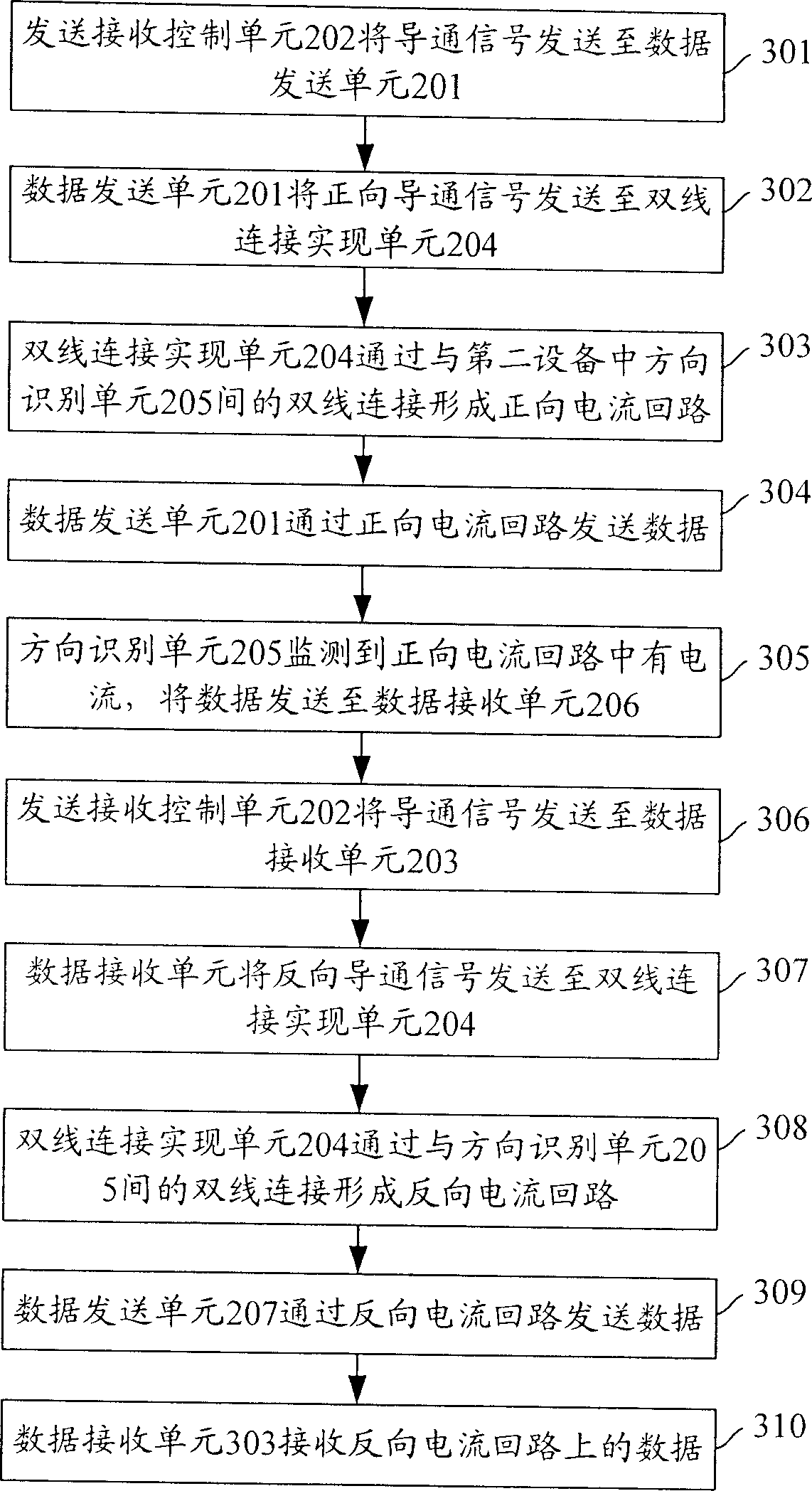

Method, system and equipment for carrying out data transmission through circuit of electric current loop

ActiveCN1874172AWill not cause overflowImprove reliabilityTransmission control/equlisationDevice formControl data

The invention discloses method for carrying out data transmission by using circuit of electric current loop. The method includes steps: using double line to connect first device to second device; using connection of double line with second device, the first device forms positive going current loop, and sends data to the second device through the formed positive going current loop; using connection of double line with second device, the first device forms back current loop, and receives data sent from the second device through the formed back current loop. In the invention, communication party controls procedures for sending and receiving data so as to raise reliability of communication procedure. The invention reduces complexity of implemented circuit, and lowers cost of circuit, possessing large practicability.

Owner:TENDYRON CORP

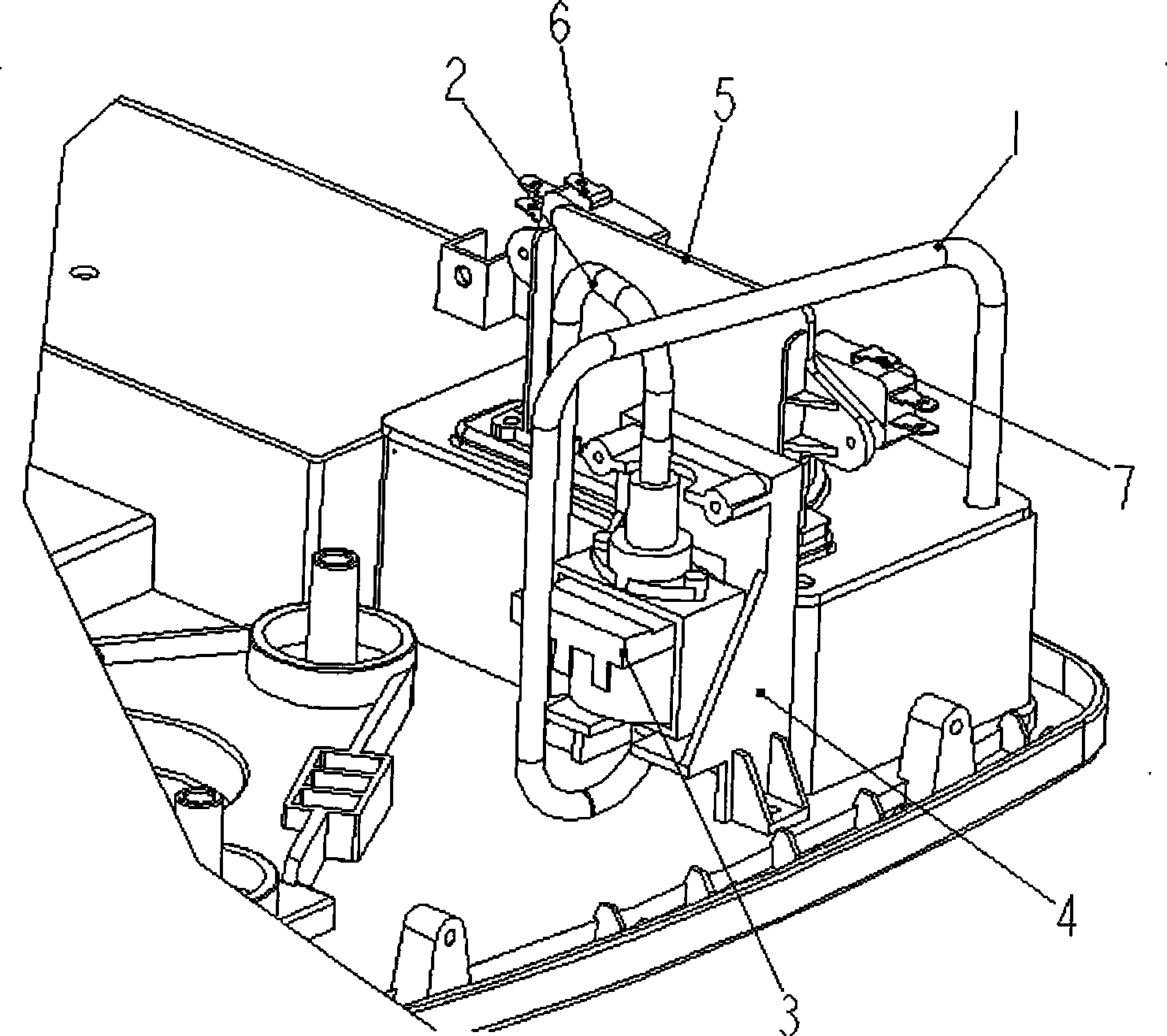

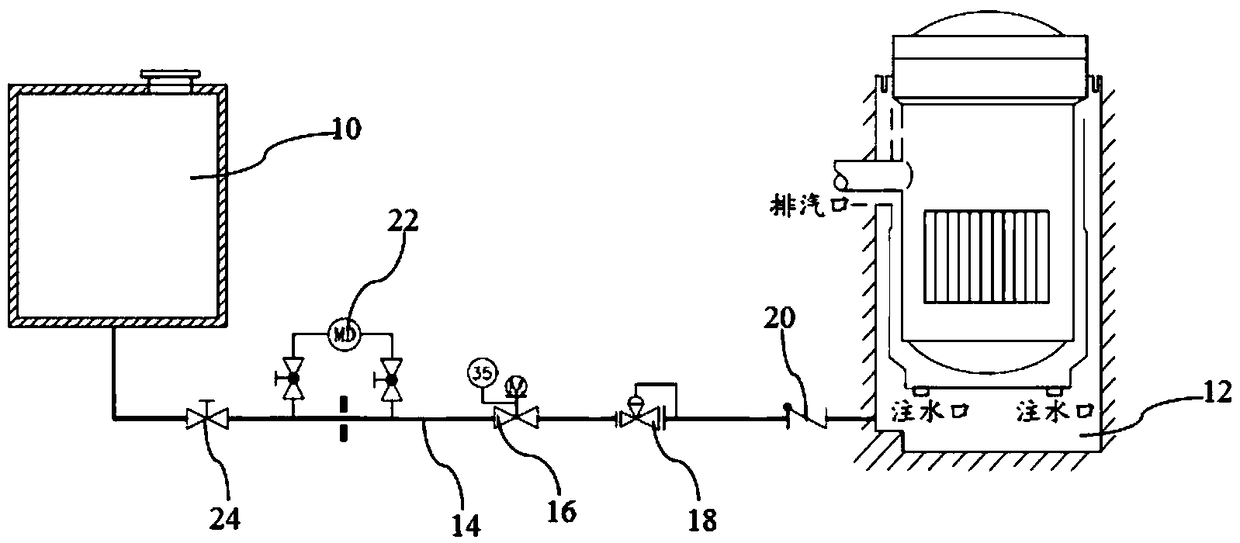

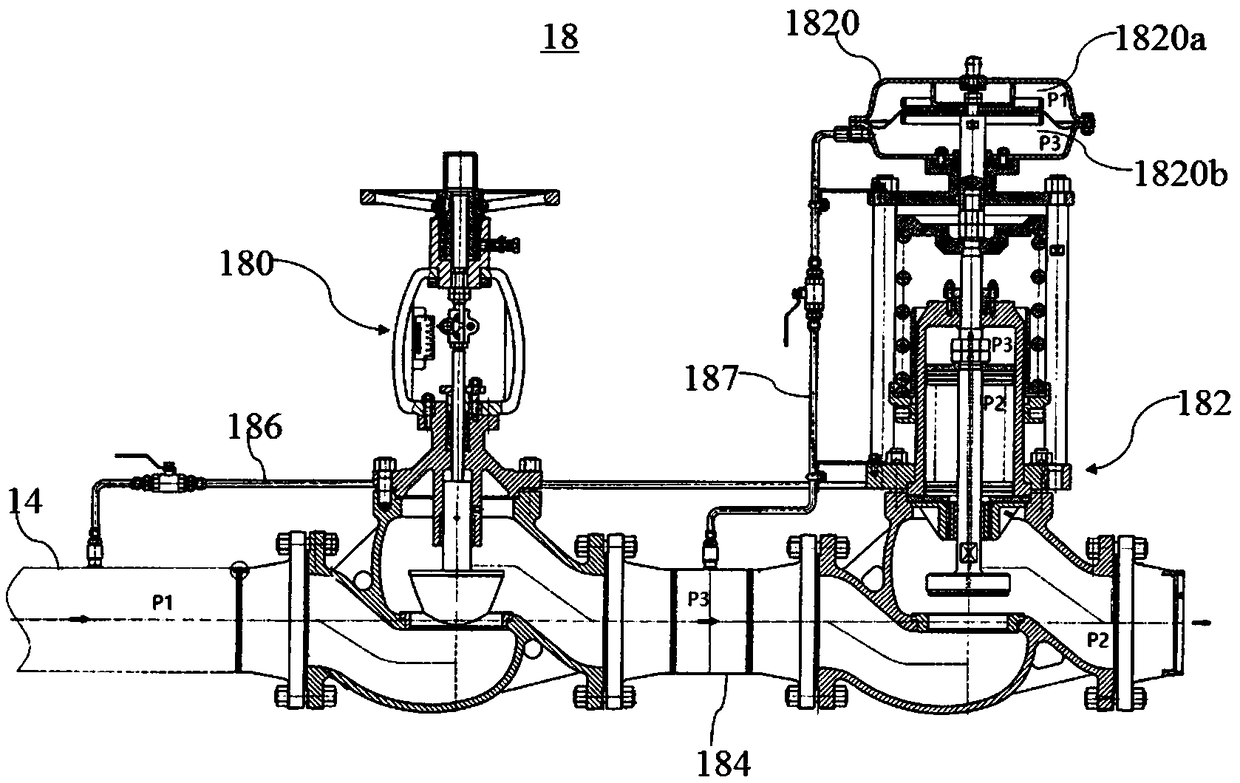

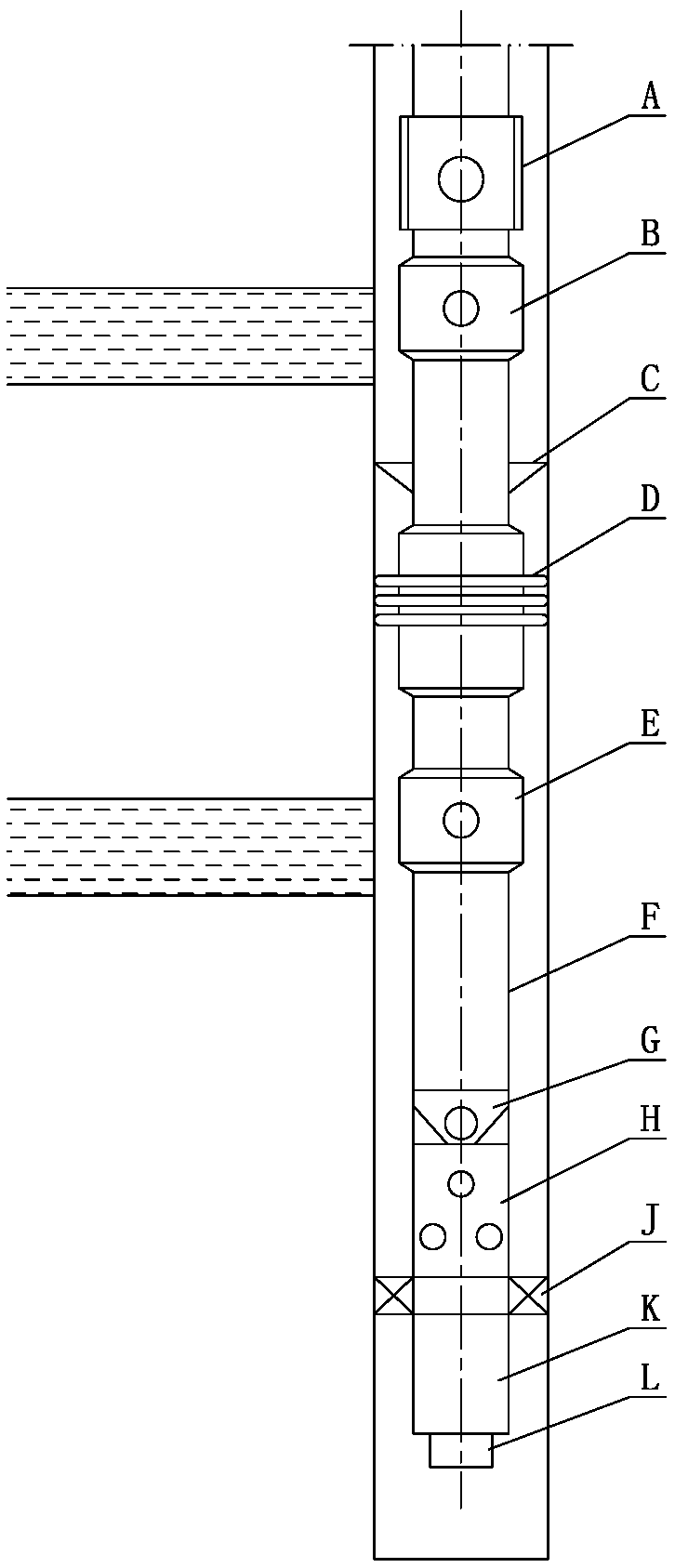

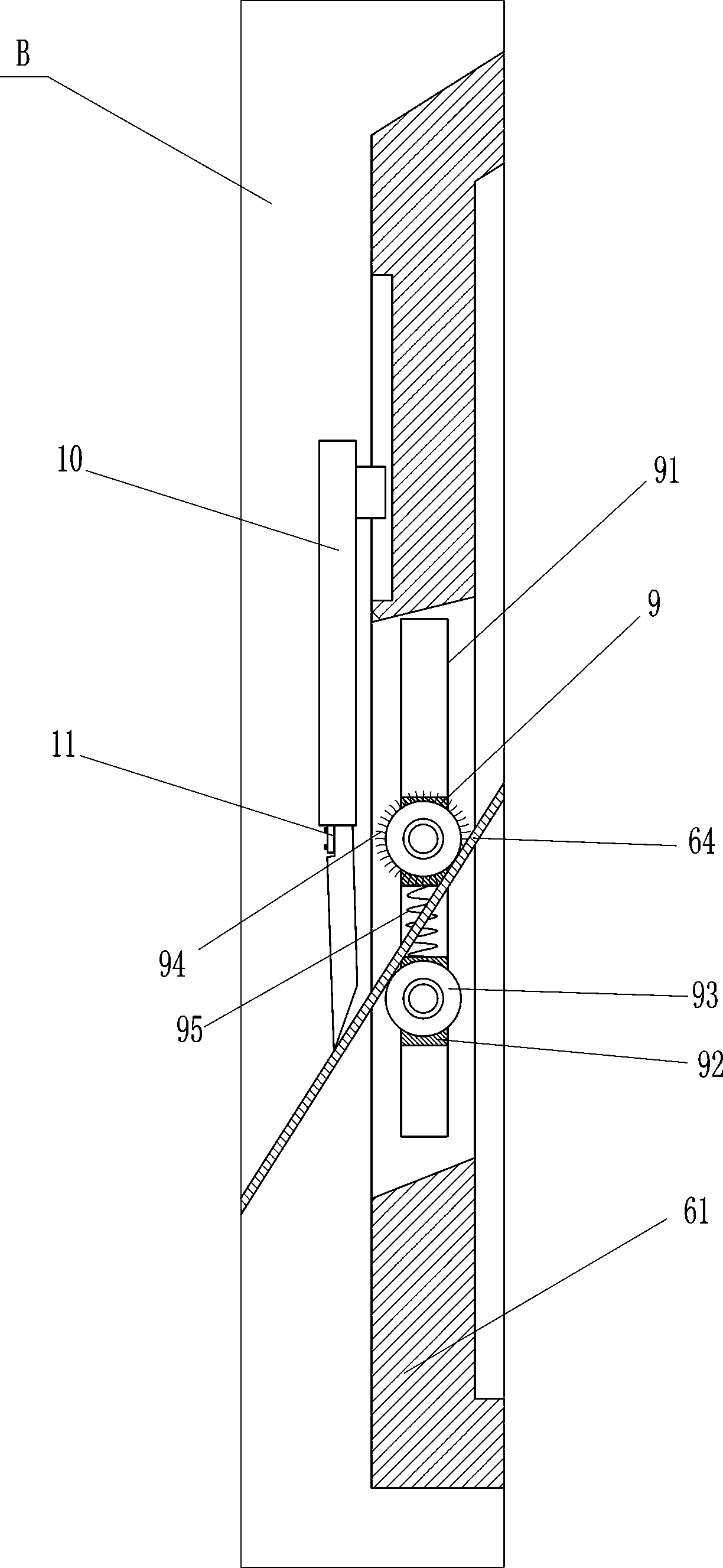

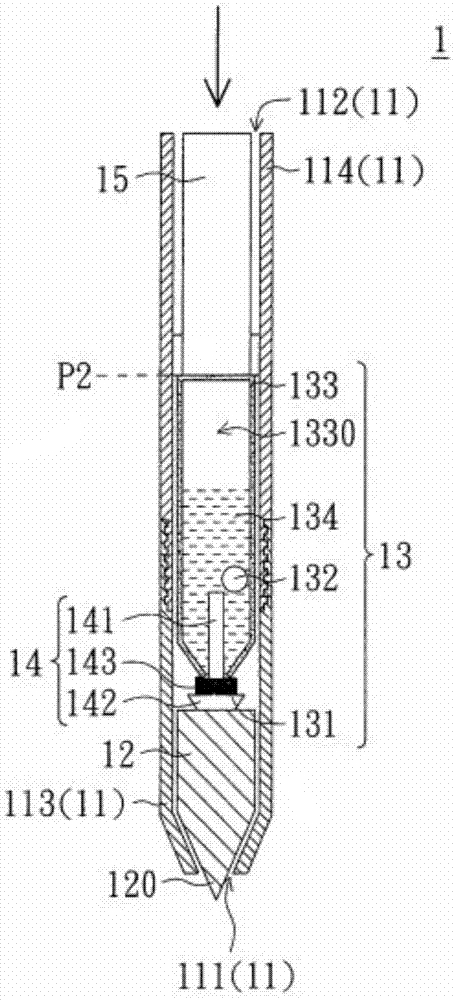

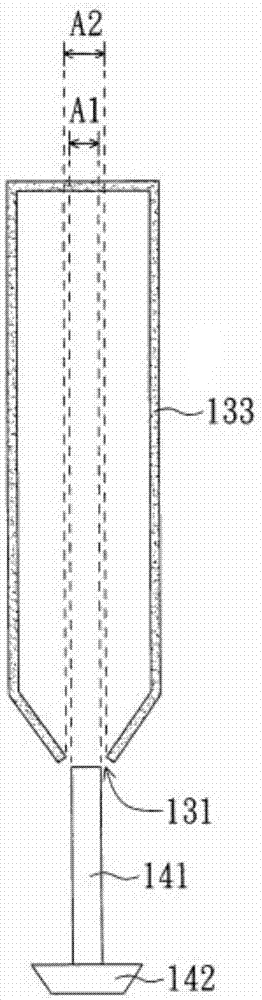

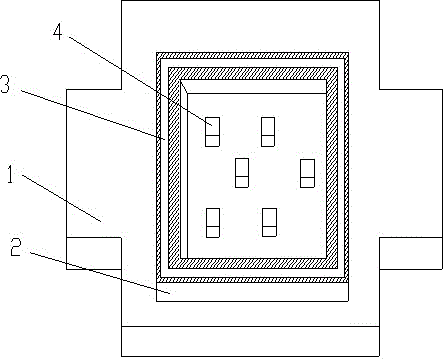

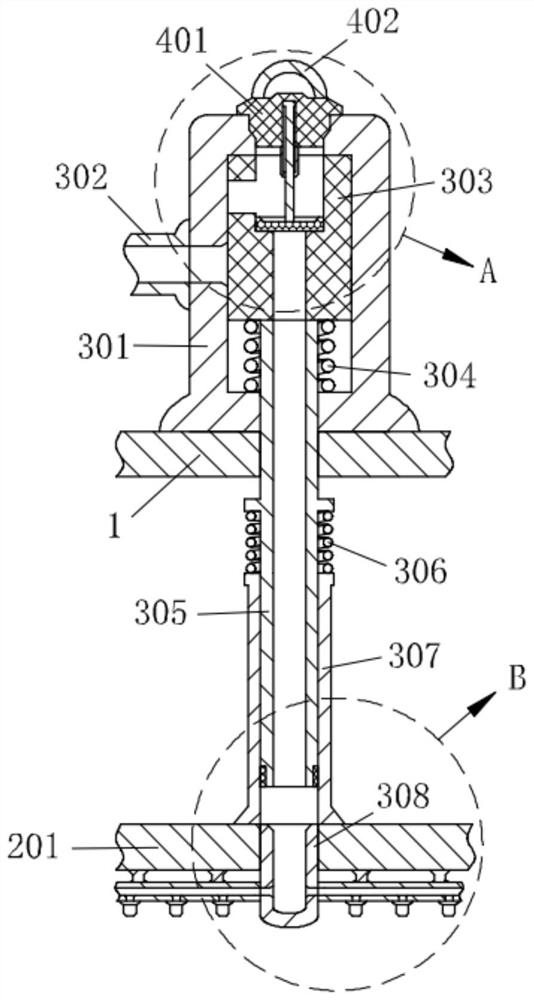

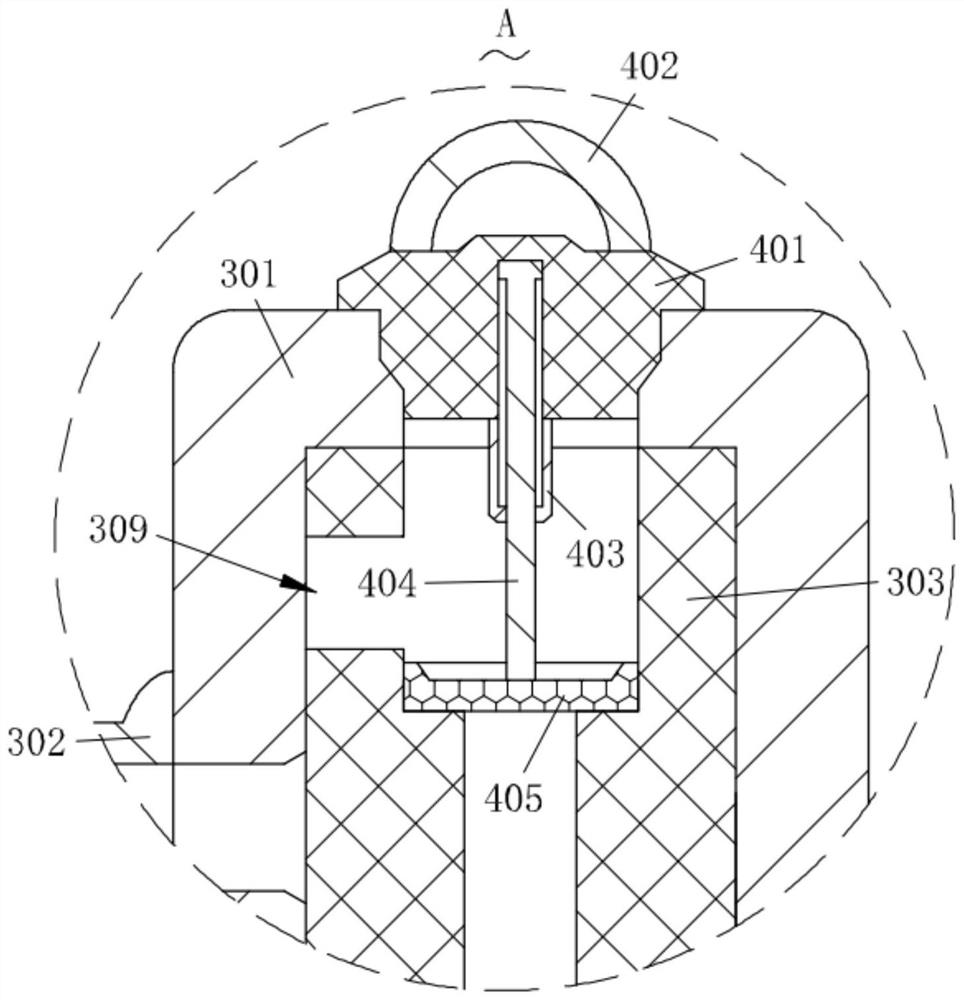

Nuclear power plant passive reactor cavity water injection system

PendingCN109243636AStable water injection processSmall fluctuation rangeNuclear energy generationCooling arrangementStable stateNuclear plant

The invention discloses a nuclear power plant passive reactor cavity water injection system. The nuclear power plant passive reactor cavity water injection system comprises a water injection tank, a water injection pipeline, an electric isolation valve and a self-actuated flow control valve assembly, wherein the water injection tank is used for storing water, and injecting water into a reactor cavity; one end of the water injection pipeline is connected with the bottom of the water injection tank, and the other end is connected with the reactor cavity; the water injection pipeline is used forinjecting water in the water injection tank into the reactor cavity; the electric isolation valve is arranged on the water injection pipeline, and is used for controlling the communication or isolation between the water injection tank and the reactor cavity; the self-actuated flow control valve assembly is arranged on the water injection pipeline between the electric isolation valve and the reactor cavity, takes potential energy of the water in the water injection tank as a power source, and is used for keeping water injection flow of the water injection tank in an approximately-stable state.Compared with the prior art, the nuclear power plant passive reactor cavity water injection system has the advantages of simple structure, convenience in arrangement, stable flow control, low requirement on water injection tank distribution, saving in water resources, and capability of improving the running safety of nuclear power plants.

Owner:中广核工程有限公司 +2

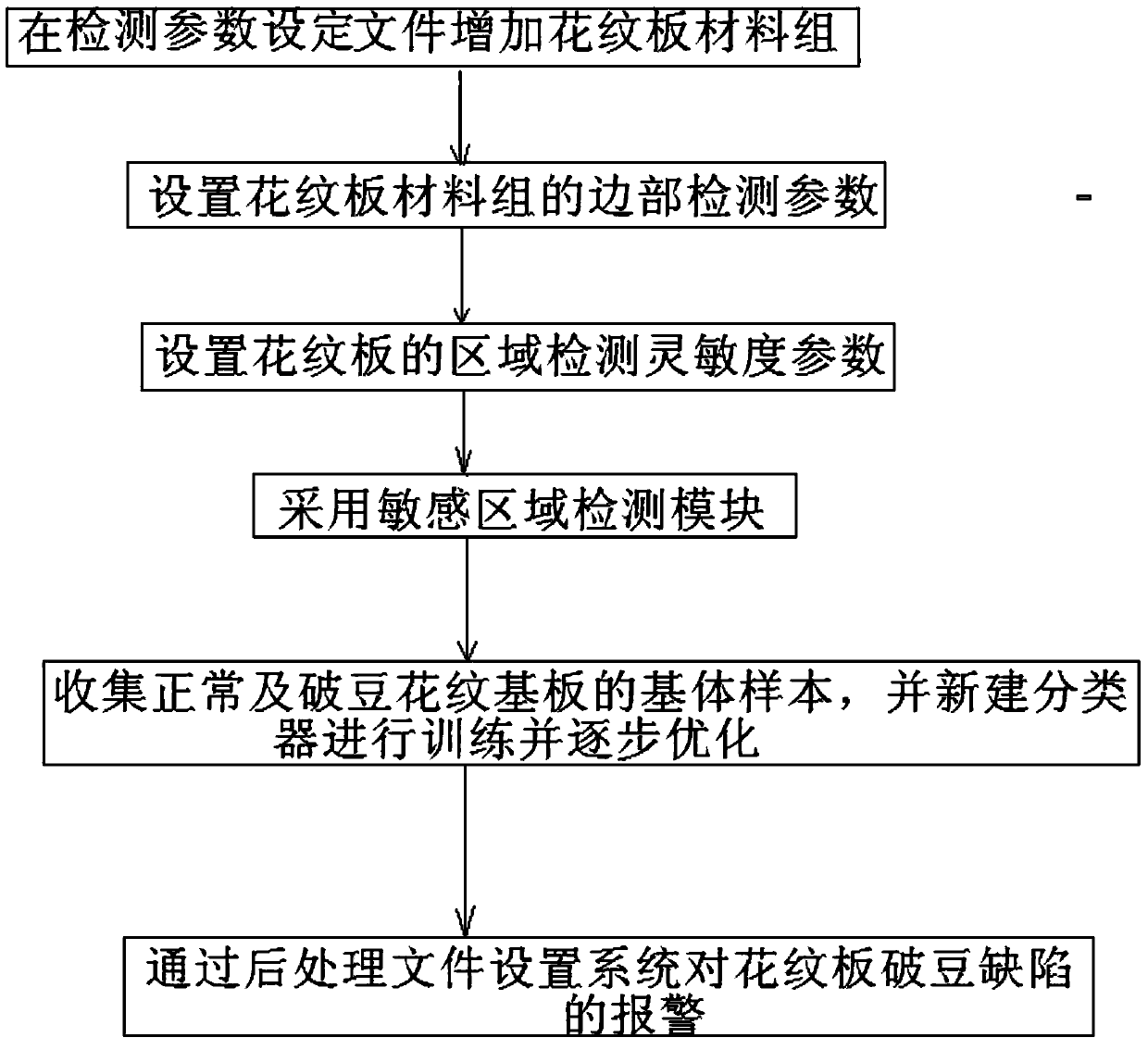

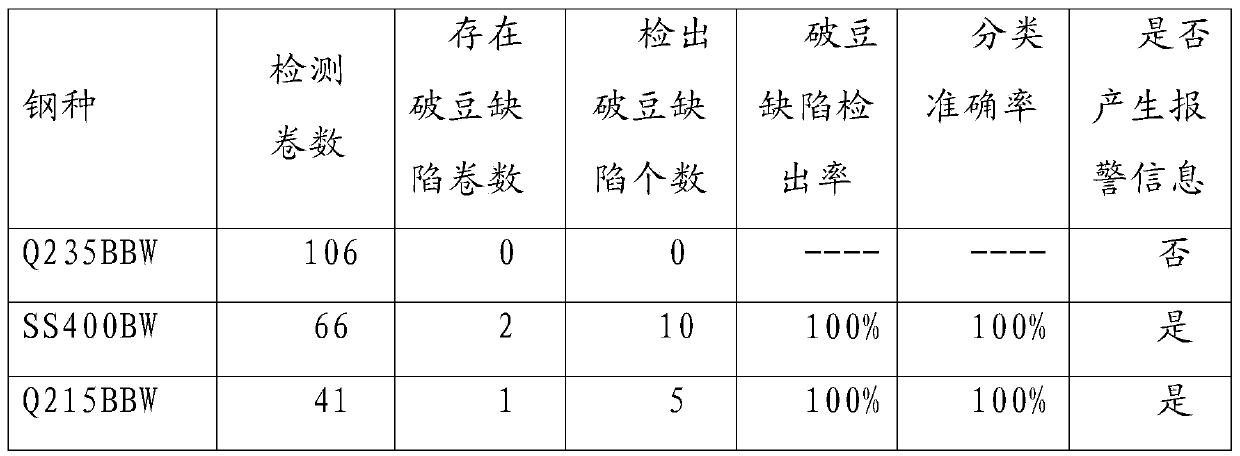

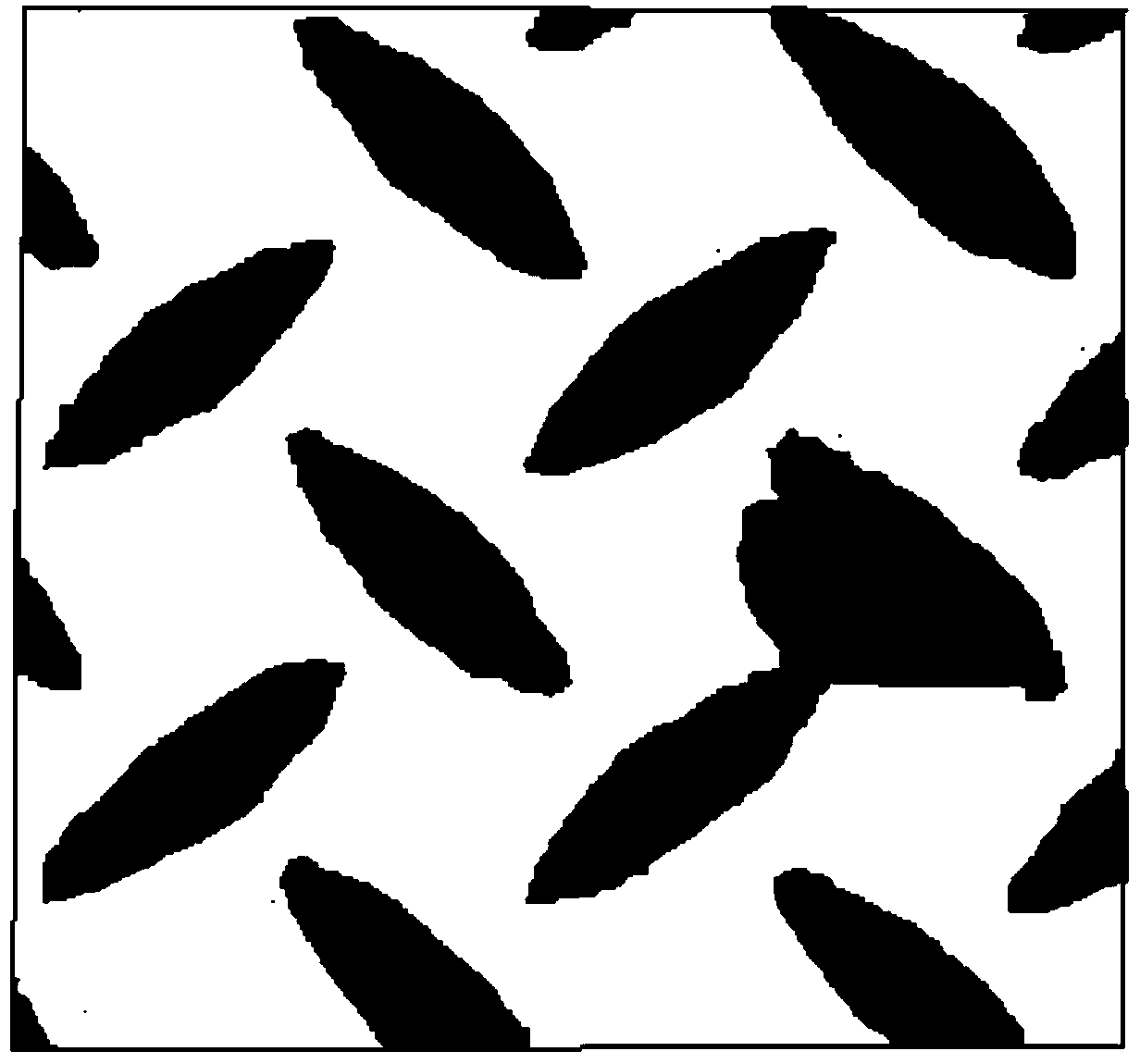

Detection apparatus and method for hot rolling Parsytec surface detection system checkered plate bean damage defect

ActiveCN103994999AAvoid Batch Quality IssuesAvoid batch quality accidentsImage analysisOptically investigating flaws/contaminationStrip steelEngineering

The present invention discloses a detection apparatus and a method for hot rolling Parsytec surface detection system checkered plate bean damage defect, and belongs to the technical field of hot rolling strip steel surface detection. The detection method comprises: 1, configuring a file to increase a checkered plate material set; 2, applying a standard edge portion detection module; 3, setting the detection sensitivity of the traditional hot rolling special area detection module to 0%, and setting the texture fitness to 100%; 4, adopting a sensitive area detection module; 5, collecting 30-50 matrix samples from a normal checkered base plate, and collecting 50-80 defect samples from a sample having bean damage defect; and 6, adopting the post-processing file setting of the system software program to make the system have the operation interface alarm function on the checkered plate bean damage defect. With the detection method, the system defect overflow can not be caused, and the batch quality accidents caused by roller bean damage are effectively avoided.

Owner:SHOUGANG CORPORATION

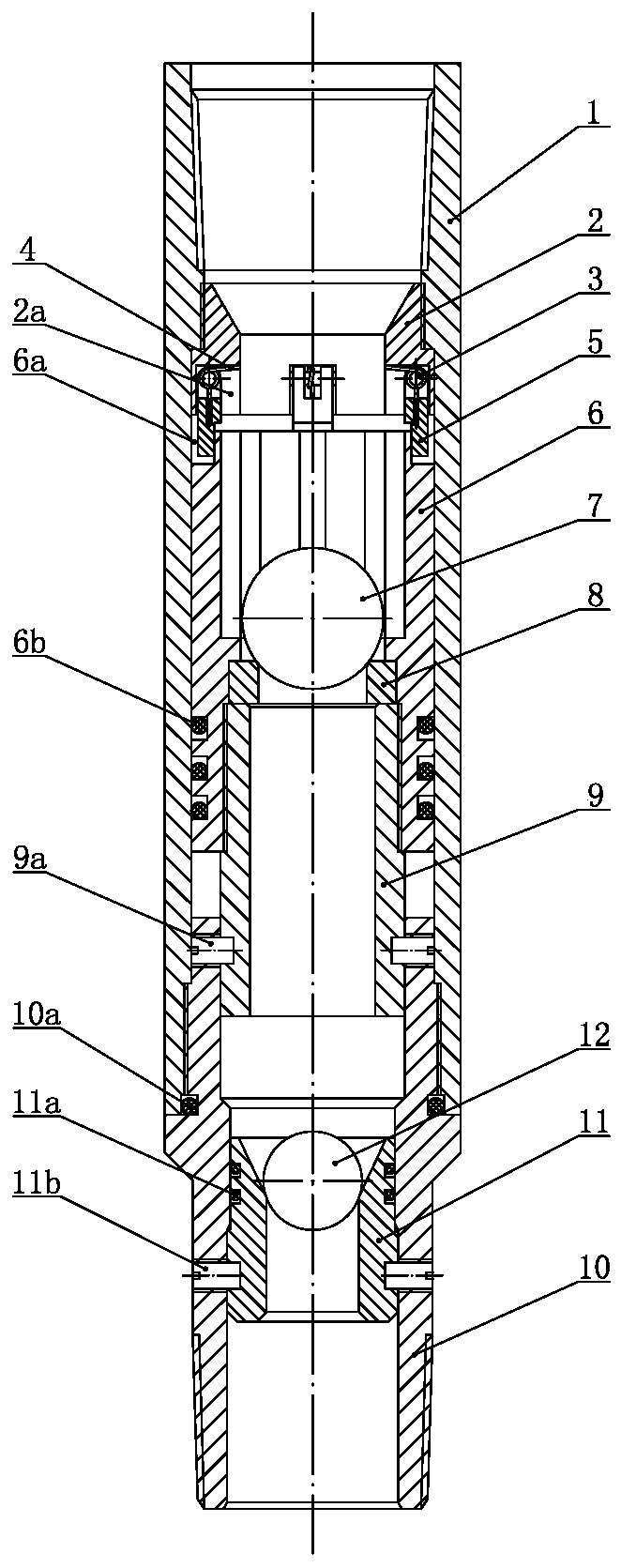

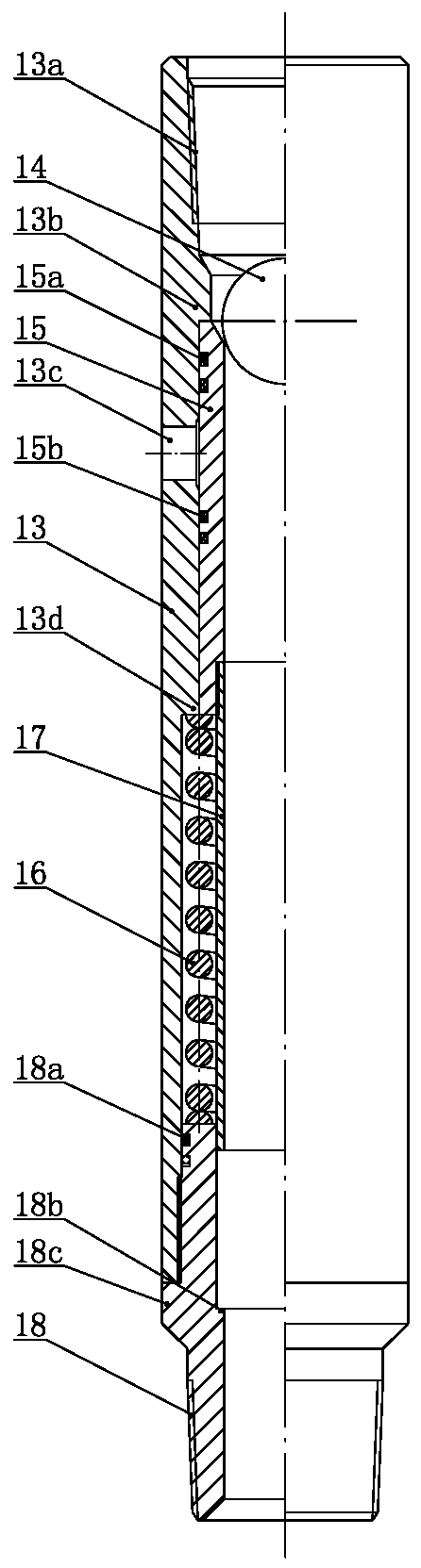

Layer-by-layer acidification and stratified water injection method

ActiveCN110439510AShorten the timeWill not cause overflowCleaning apparatusWell/borehole valve arrangementsTruckPre treatment

The invention relates to a layer-by-layer acidification and stratified water injection method. The method comprises the following steps in sequence that an acid injection integrated tubular column isput into a casing, pretreatment fluid and respective acid liquor of upper and lower strata are prepared, after the positive circulation of fluid is normal, the positive substitution of the pretreatment fluid is carried out, a 31mm steel ball is dropped into a acidizing single flow valve, and a cement truck forward presses to set a packer; the cement truck continues to boost the pressure, shears ashear pin of an inner sleeve ball seat, and the inner sleeve ball seat falls into an inner coated tubing; lower acid liquor is then sent down a well, flows from a screen and enters into a lower waterinjection layer; another a 48mm soluble ball is dropped into a switch valve for setting, the pretreatment fluid is forward pressed to open an acid liquor channel of a barrel wall of the switch valve,and then upper acid liquor is injected into an upper water injection layer; then the well is closed, and two strata continue to acidify; after the acidification reaction is complete, and the soluble ball is dissolved; and a 40mm sealing steel ball is put in, and water is injected normally after tests of throwing and retrieving and sealing are qualified. According to the method, only one trip is needed, the operation cost is low, a well occupancy period is short, the development cost of an oilfield is reduced, and the environmental benefit is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Filter pressing device for producing amino acid

InactiveCN105999834AWill not cause overflowSmall particle diameterFiltration circuitsFilter pressMachining process

The invention discloses a filter pressing device for producing amino acid. The filter pressing device comprises a pressing head and a funnel; the inner diameter of the funnel is matched with the outer diameter of the pressing head; the pressing head can be pressed into the funnel; and one group of counter bores are uniformly formed in the bottom of the pressing head. Compared with the prior art, a whole filter pressing process has a certain air pressure gap all the time through the design of the pressing head and the counter bores on the funnel in the aspect of manufacturing; the overflowing, even splashing of an intermediate are not caused and the production efficiency of filter pressing can also be effectively controlled, so that the peripheral environment of a filter pressing field is protected; and meanwhile, a biological film is matched with the filter pressing in the design so that the grain diameter of the intermediate subjected to filter pressing is reduced, a foundation is laid for rapidly entering a next path of fine machining process and the quality of products is also ensured.

Owner:宜兴市前成生物有限公司

Ice machine control method, ice machine and computer readable storage medium

ActiveCN110274415AAvoid ice jamsNo lossLighting and heating apparatusIce productionIce storageEnergy loss

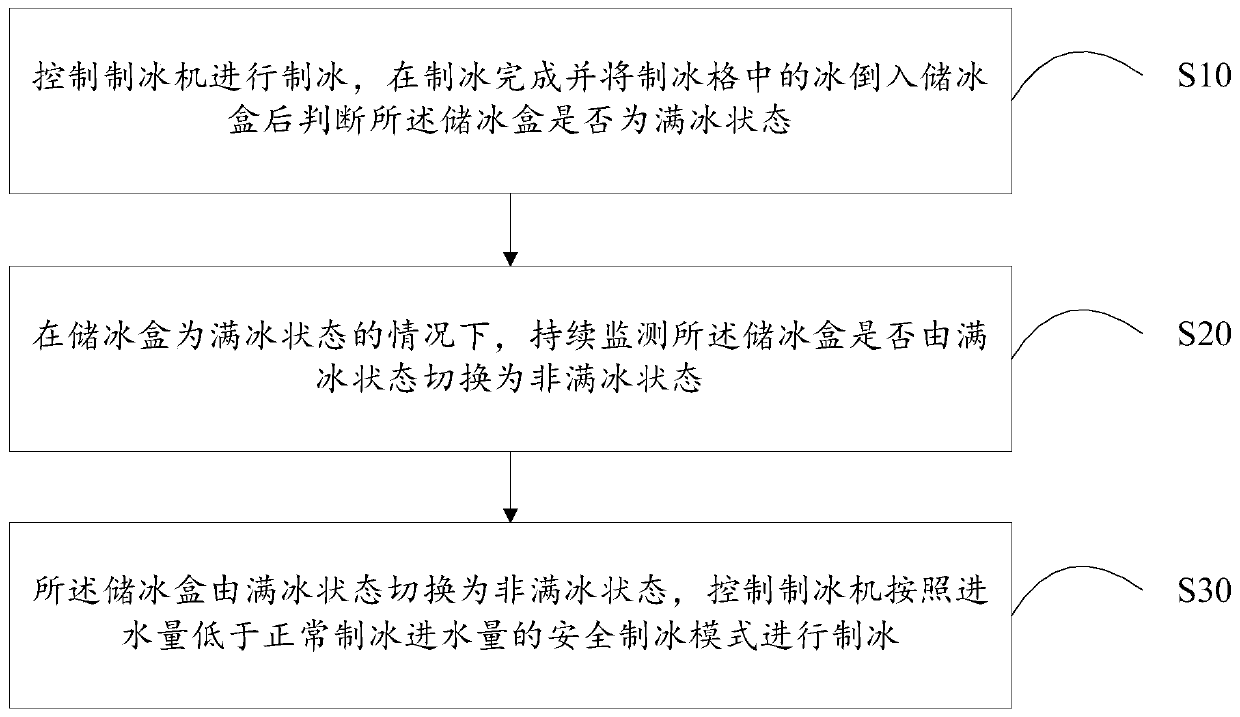

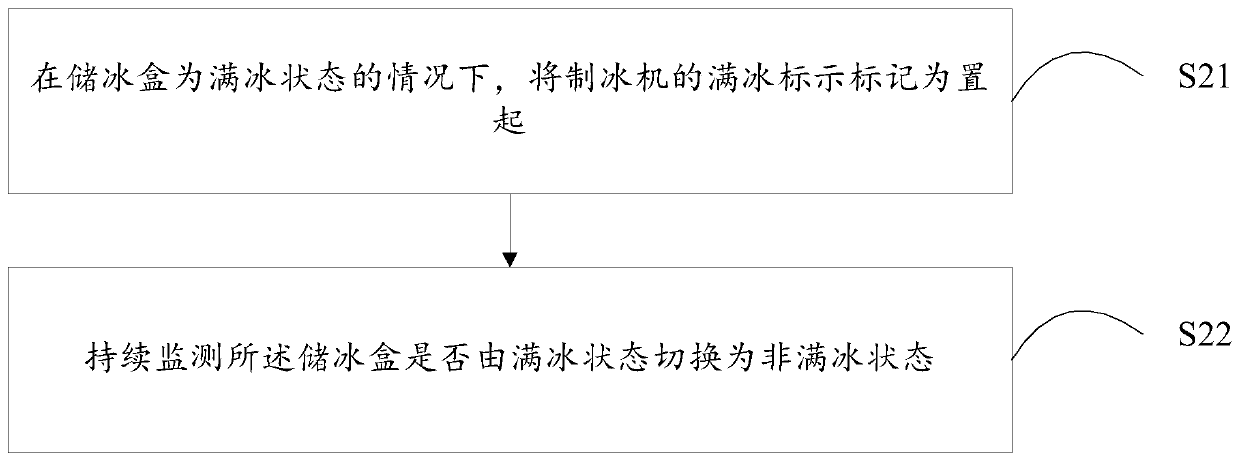

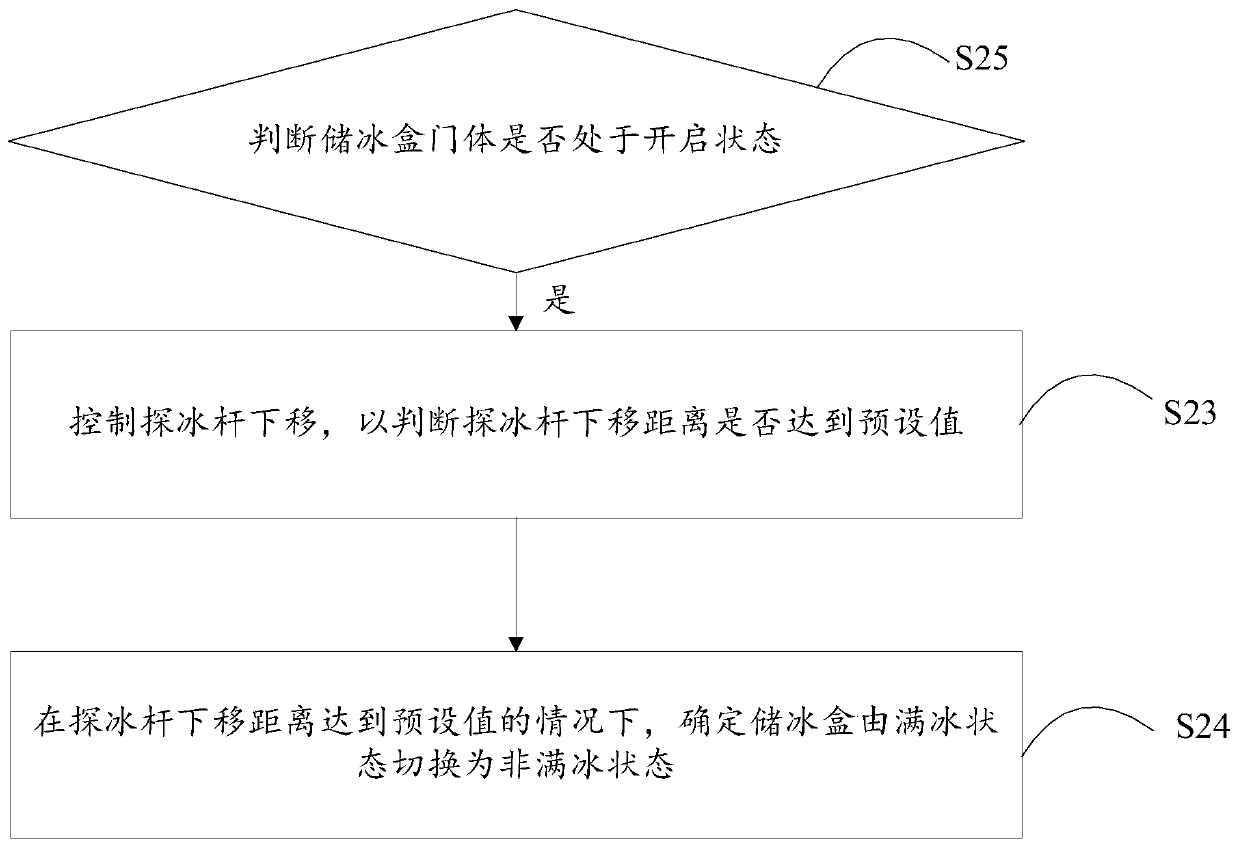

The invention discloses an ice machine control method, an ice machine and a computer readable storage medium. The ice machine comprises an ice storage box and ice cells. The method comprises the following steps: the ice machine is controlled to produce ice; after the ice production is finished, and ice in the ice cells is poured into the ice storage box, the ice storage box is judged in a full ice state or not; when the ice storage box is in the full ice state, the ice storage box is continuously monitored to switch from the full ice state to a non-full ice state or not; and when the ice storage box is switched from the full ice state to the non-full ice state, the ice machine is controlled to produce the ice according to a safety ice production mode of a water inlet quantity lower than a normal ice production water inlet quantity. Through arrangement of the safety ice production mode, broken ice at he bottom of the ice machine is used as raw materials to feed in the ice production, so that the ice blockage problem is prevented, the additional energy loss is not caused, and the ice storage environment is not influenced.

Owner:HEFEI HUALING CO LTD +2

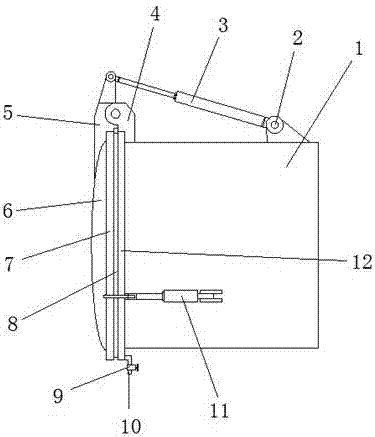

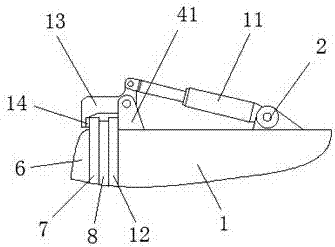

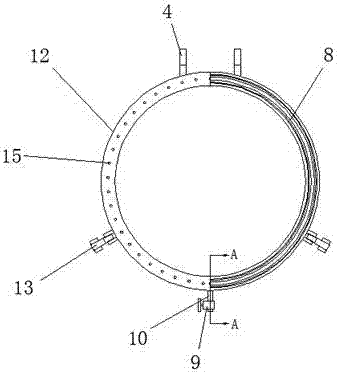

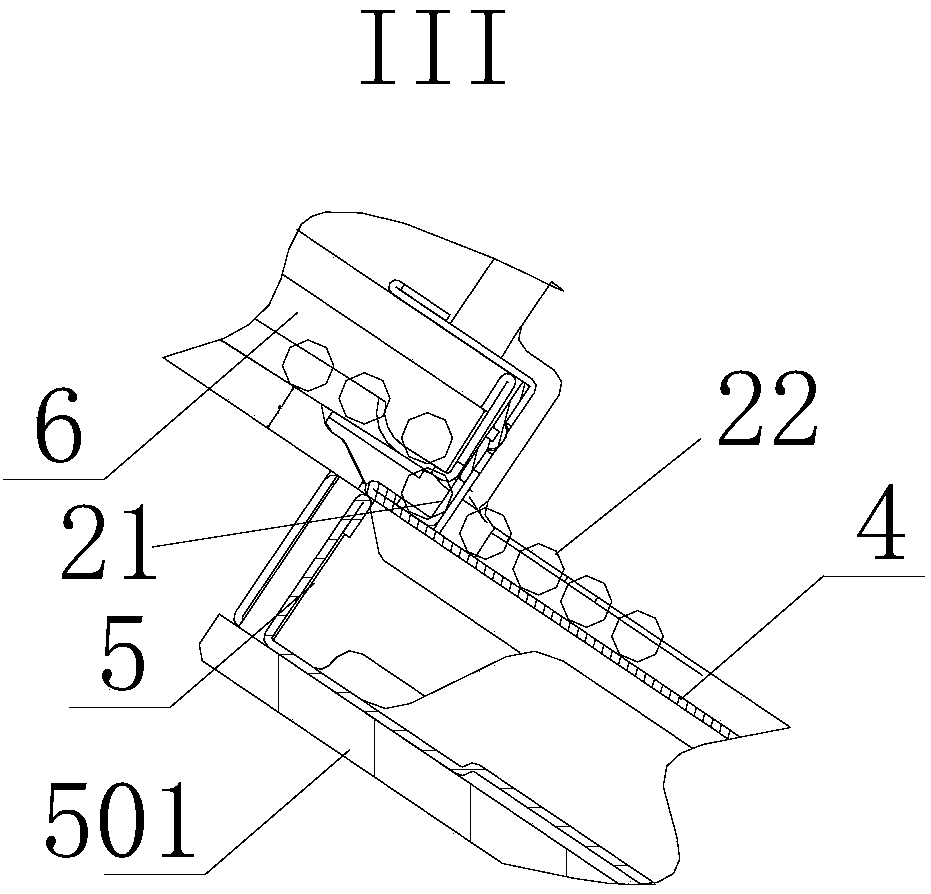

Locking and sealing device of tank body and rear cover of suction-type sewer scavenger

The invention discloses a locking and sealing device for the back cover of a tank body of a sewage suction vehicle, which comprises a tank body, a first bracket is fixedly connected to the upper left side of the tank body, and a connecting bracket is movably connected to the upper end of the first bracket through a hinge. The upper end of the connecting plate is movably connected with a rear cover opening device through a hinge, the lower end of the connecting plate is fixedly connected with a rear cover, one side of the rear cover is fixedly connected with a first ring body, and the first ring One side of the tank body is fixedly connected with a sealing ring, and the left side of the tank body is fixedly connected with a second ring body, and several groups of exhaust holes are evenly distributed in the left inner cavity of the second ring body, and the second ring body is fixedly connected with a second ring body. An air collecting ring is opened in the inner cavity of the ring body, and an air pipe is fixedly connected to the right side of the bottom of the second ring body, and an air valve is fixedly installed in the middle of the air pipe. The invention is convenient and practical, effectively prevents the failure of cooperation between the back cover and the tank body, does not cause secondary pollution caused by garbage overflow in the tank body, and better ensures the tight cooperation between the back cover and the tank body.

Owner:宿迁洁丽环保设备制造有限公司

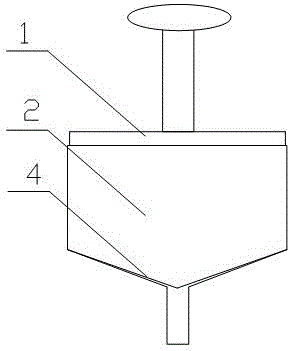

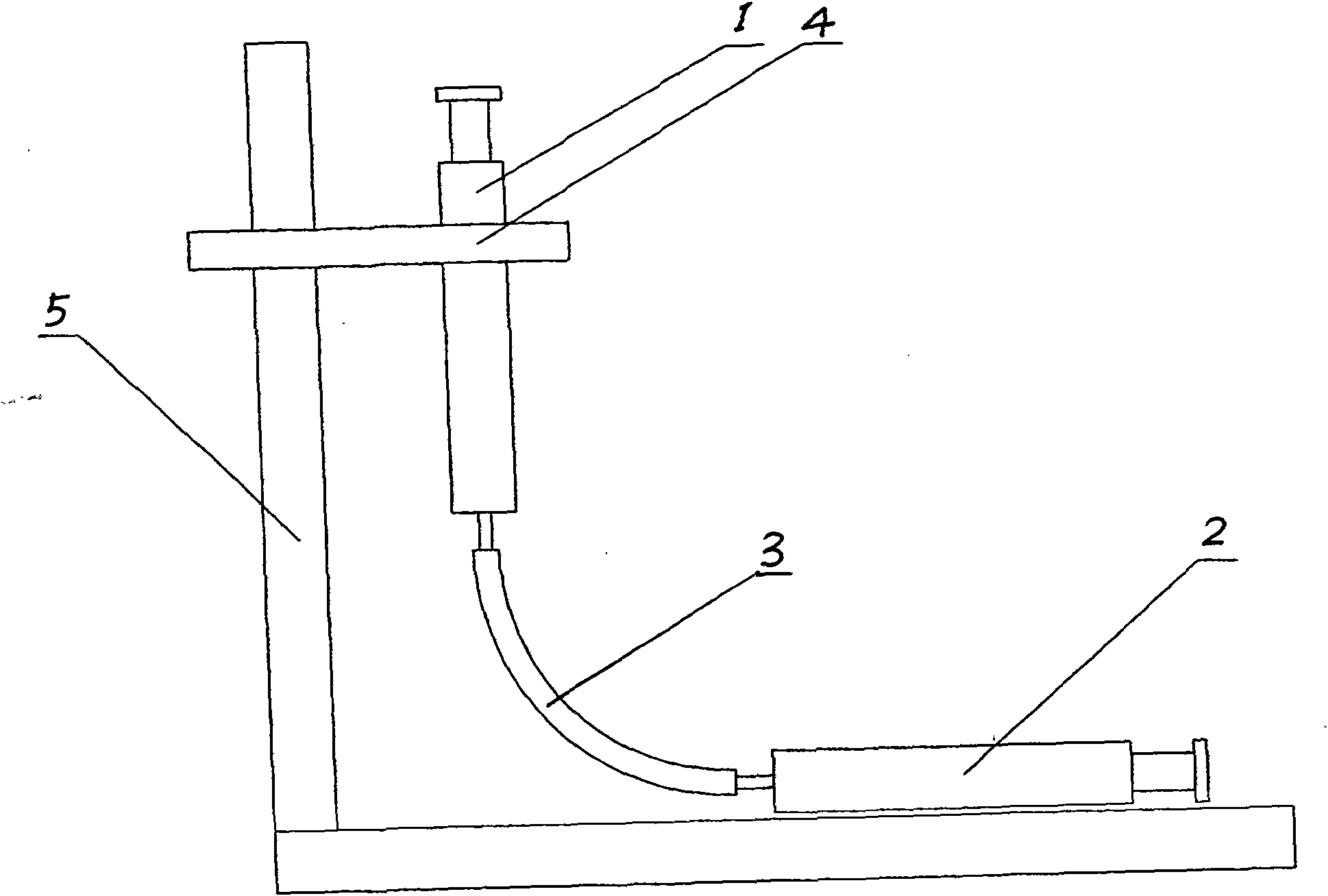

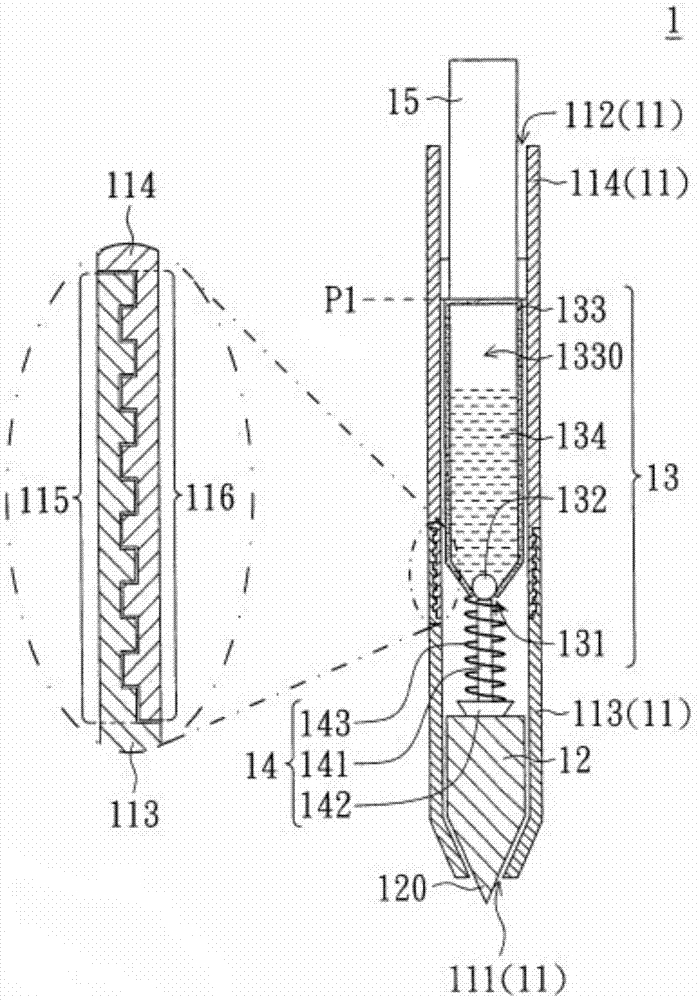

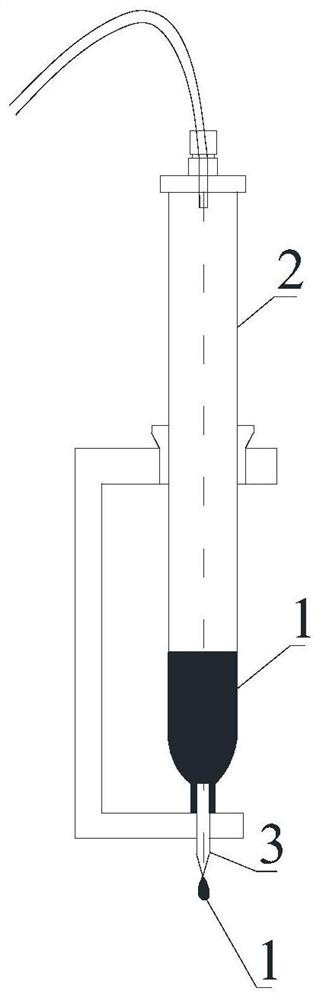

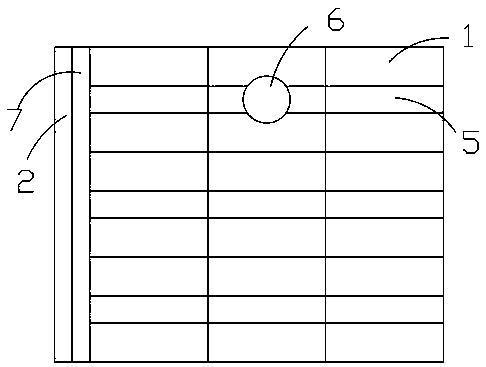

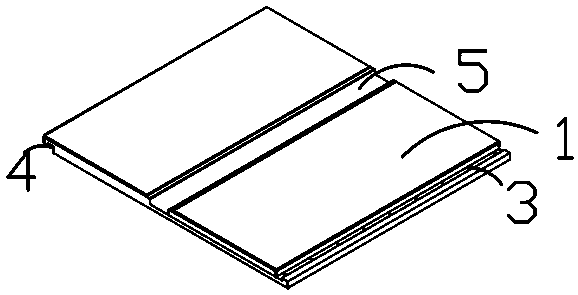

Experiment demonstration device of copper and concentrated nitric acid reaction

InactiveCN102723029AWill not cause overflowStimulate the desire to experiment and exploreEducational modelsToxic gasNitrogen dioxide

The invention provides an experiment demonstration device of a copper and concentrated nitric acid reaction. The device mainly comprises a transparent plastic shell injector (1), a transparent plastic shell injector (2), a connecting flexible pipe (3), a fixing iron clamp (4) and a fixing support (5). The device is characterized in that: the transparent plastic shell injector (1) is vertically fixed on the fixing iron clamp (4), and the transparent plastic shell injector (1) and the transparent plastic shell injector (2) are connected by a connecting flexible pipe (3). The device has the following advantages: (1) a method of operating the copper and concentrated nitric acid reaction in a sealed device is employed, a reaction rate can be controlled, the reaction can be stopped at any time, the overflow of a toxic gas nitrogen dioxide is not prevented, and the method is safe and environmentally friendly; (2) a life material or a waste material beside a student is taken as a test material, which is in accordance with the spirit of the new curriculum reform, an experimental exploration desire of the student can be simulated, and a saving consciousness is reflected; (3) operation is simple, materials are easy to obtain, and experiment cost is saved.

Owner:戴荣华

Flip type garbage collection box capable of uniformly pouring garbage

ActiveCN110937289ASave human effortLabor savingWaste collection and transferRefuse vehiclesGarbage collectionTruck

The invention relates to a garbage collection box, and particularly relates to a flip type garbage collection box capable of uniformly pouring garbage. The invention aims to provide the flip type garbage collection box capable of uniformly pouring garbage in a garbage can into a garbage truck, and manpower can be saved during pouring. The flip type garbage collection box capable of uniformly pouring the garbage comprises a garbage collection box body, a cover plate, air cylinders, a placing seat and the like, wherein the top of the garbage collection box body is hinged to the cover plate; thecover plate is used for covering the top of the garbage collection box body; the air cylinders are rotationally mounted on the front wall and the rear wall of the garbage collection box body; and telescopic rods of the air cylinders are hinged to the bottom of the cover plate. According to the garbage collection box, the garbage can is placed in the placing seat firstly, then the garbage in the garbage can is poured into the garbage collection box by opening the cover plate, and the garbage can only needs to be placed on the placing seat manually when the garbage collection box is used, so that the manpower is saved to a certain extent.

Owner:ZHEJIANG ZHENYANG COLD INSULATION TECH CO LTD

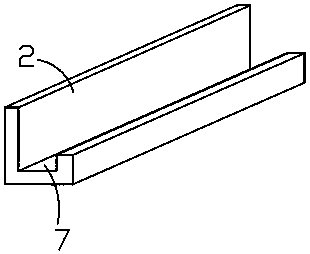

White board pen

The invention discloses a whiteboard marker, which comprises a pen tube, the pen tube includes a first nozzle and a second nozzle which are arranged oppositely, an ink guide unit and an ink supply unit are arranged inside the tube of the pen tube, and the ink guide unit includes an exposed first nozzle. A writing part outside the nozzle, the ink supply unit includes a tube body and a seal, the tube body is provided with an opening, the ink supply unit and the ink guide unit are connected by a push-off unit, and the push-off unit includes an elastic element, a cylinder and a block , the top of the ink supply unit is provided with a push rod. The invention is simple in structure, easy to replace and clean, and will not cause ink overflow.

Owner:重庆智成友和会计服务有限公司

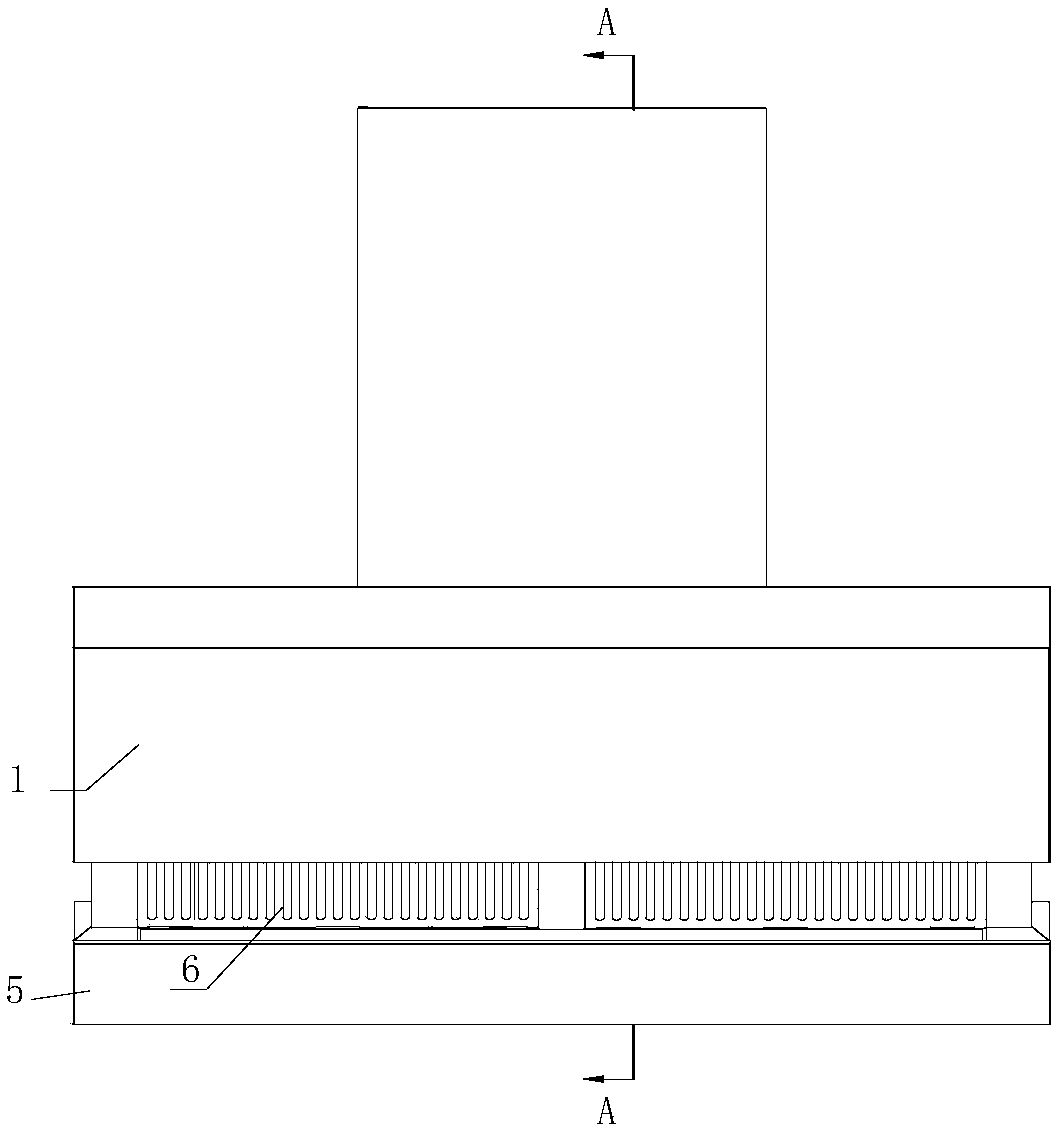

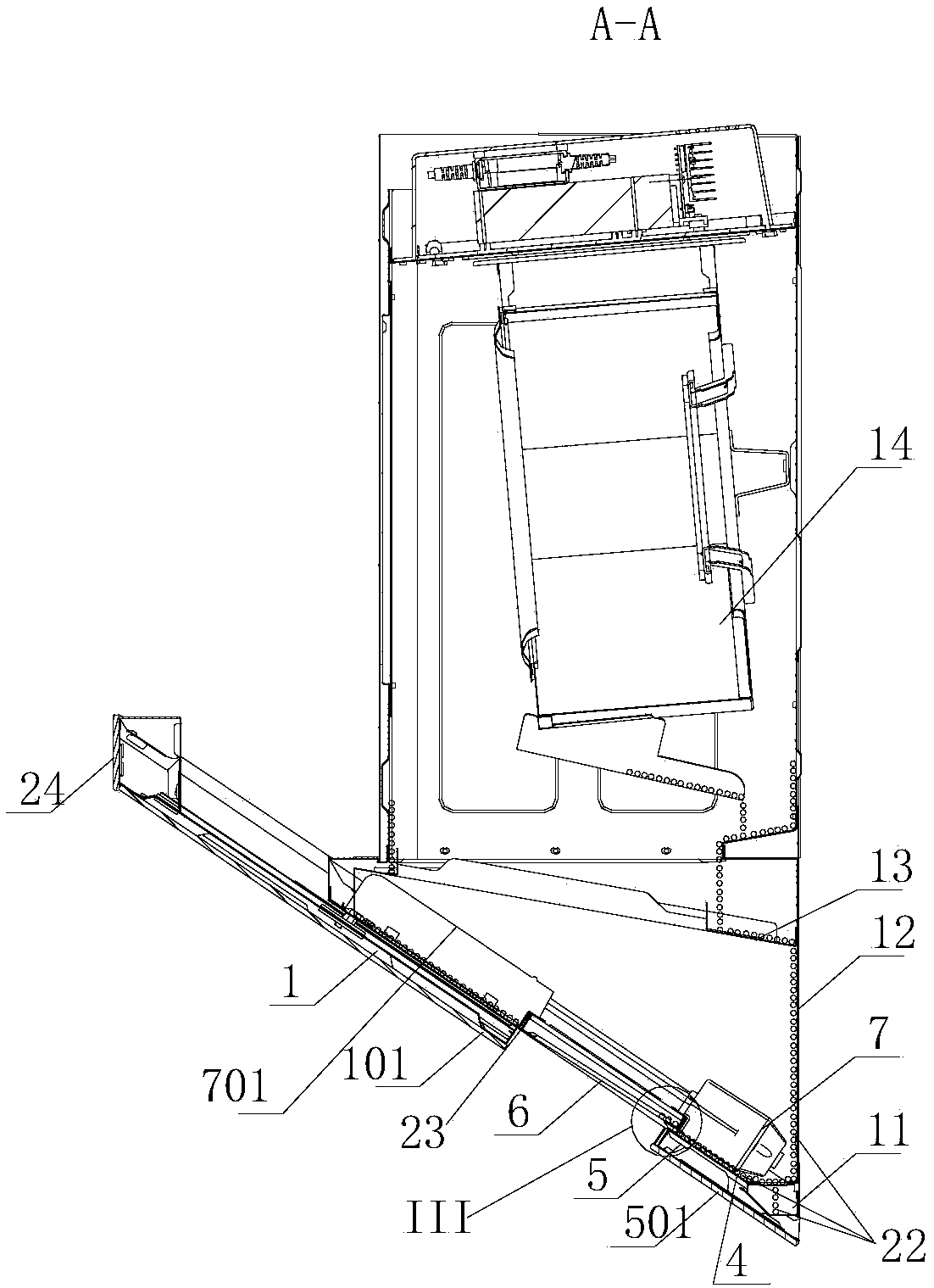

Extractor hood

PendingCN109990336AEasy to cleanLarge amount of solutionDomestic stoves or rangesLighting and heating apparatusEngineeringL# .NET

The invention discloses an extractor hood. The extractor hood comprises a shell, a smoke absorbing port is formed in the shell, the extractor hood comprises an oil net installed on the smoke absorbingport, the oil net is inclined and fixed relative to the smoke absorbing port, the oil net is a flat plate body, and at least one side of the oil net is separated from the edge of the smoke absorbingport and forms a gap with the smoke absorbing port. The extractor hood well solves the problem that the oil smoke is large and urgent in the oil net through oil discharge gaps formed in the oil net and the smoke absorbing port, greatly reduces the oil pollution accumulation on the lowest surface of the oil net, and solves the problem that oil droplet particles are large and form a concentrated problem in a short period of time on the lowest surface of the oil net, so that most of the oil droplets can smoothly flow into an oil cup as soon as possible, oil pollution overflowing is not caused, the sanitary dead corner is reduced, and the extractor hood is easier to clean.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

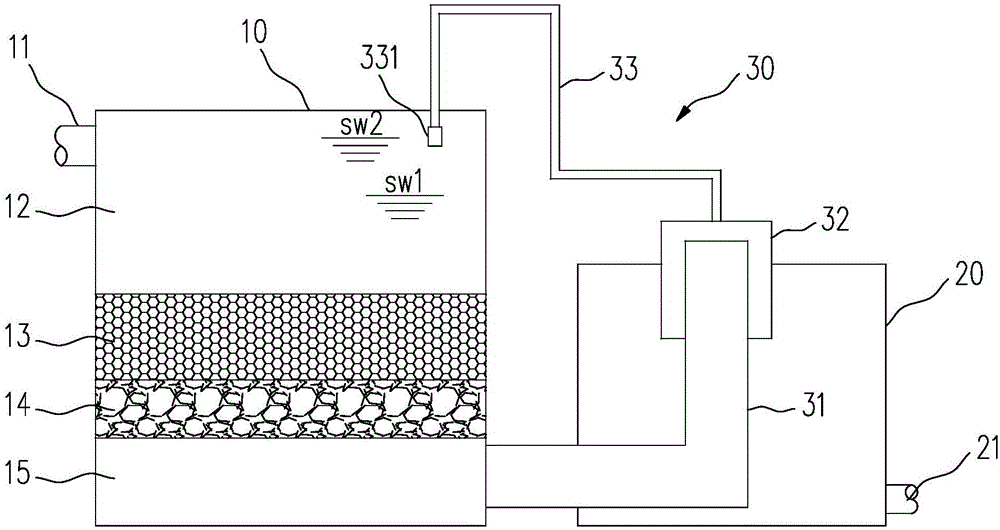

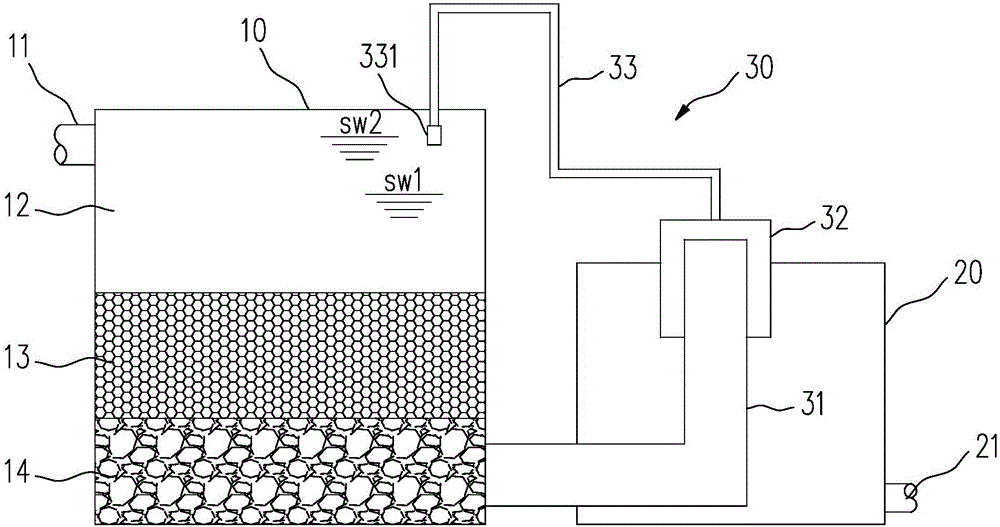

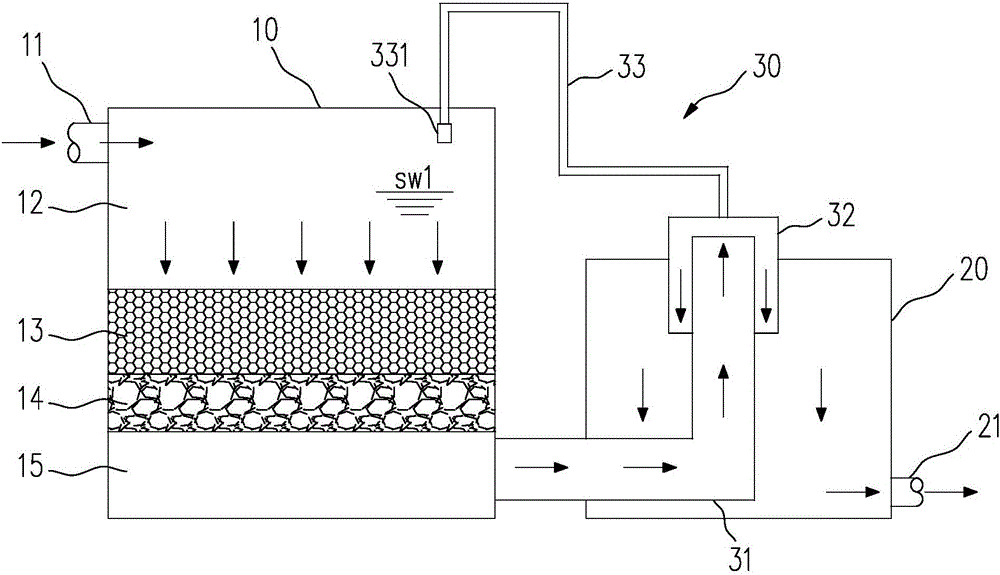

Constant-water-level filtration and back flush integrated device and control method

ActiveCN105771341ASimple structureRun smoothlyLoose filtering material filtersGravity filtersData transmissionWater storage tank

The invention belongs to the technical field of filtration devices, and particularly relates to a constant-water-level filtration and back flush integrated device and a control method. The device comprises a filtration pool, a water storage tank and a constant-water-level filtration device. A filter material layer is arranged in the filtration pool. The constant-water-level filtration device is provided with a lower port, a middle port and an upper port from bottom to top. The lower port is connected with a filtration pool water outlet. The middle port is communicated with the water storage tank and is lower than the filtration water level of the filtration pool. The upper port is communicated with the upper space, higher than the filtration water level, of the filtration pool. The water storage tank is set as a closed space. A water drain pipe is arranged on the lower portion of the water storage tank. The constant-water-level filtration and back flush integrated device has the advantages that frequently-operative adjusting valves are not needed, constant-water-level filtration can be realized without data transmission, and backwashing of the filter material layer can be achieved effectively; the device is simple in structure, stable constant-water-level operation, energy conservation and environment protection are achieved, and filtering and backwashing integrated control can be also realized.

Owner:HEFEI GENERAL MACHINERY RES INST +1

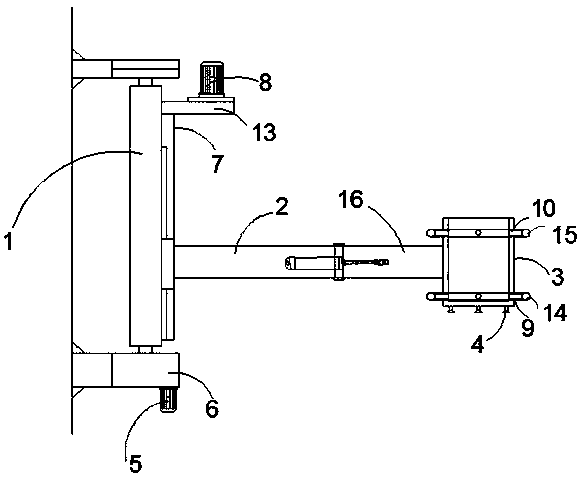

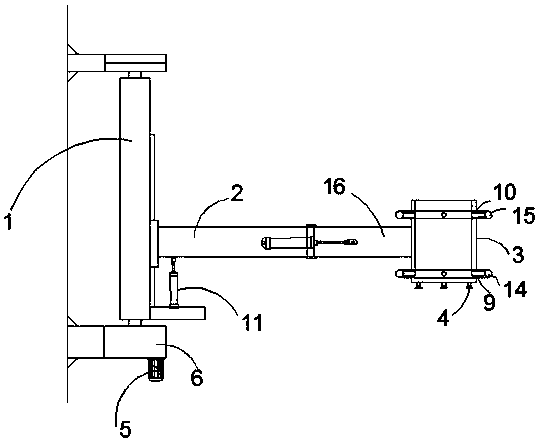

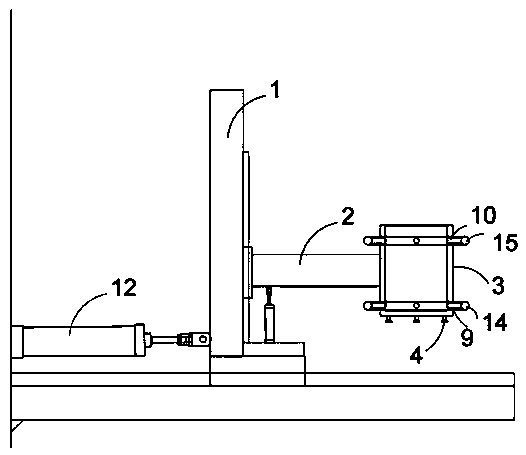

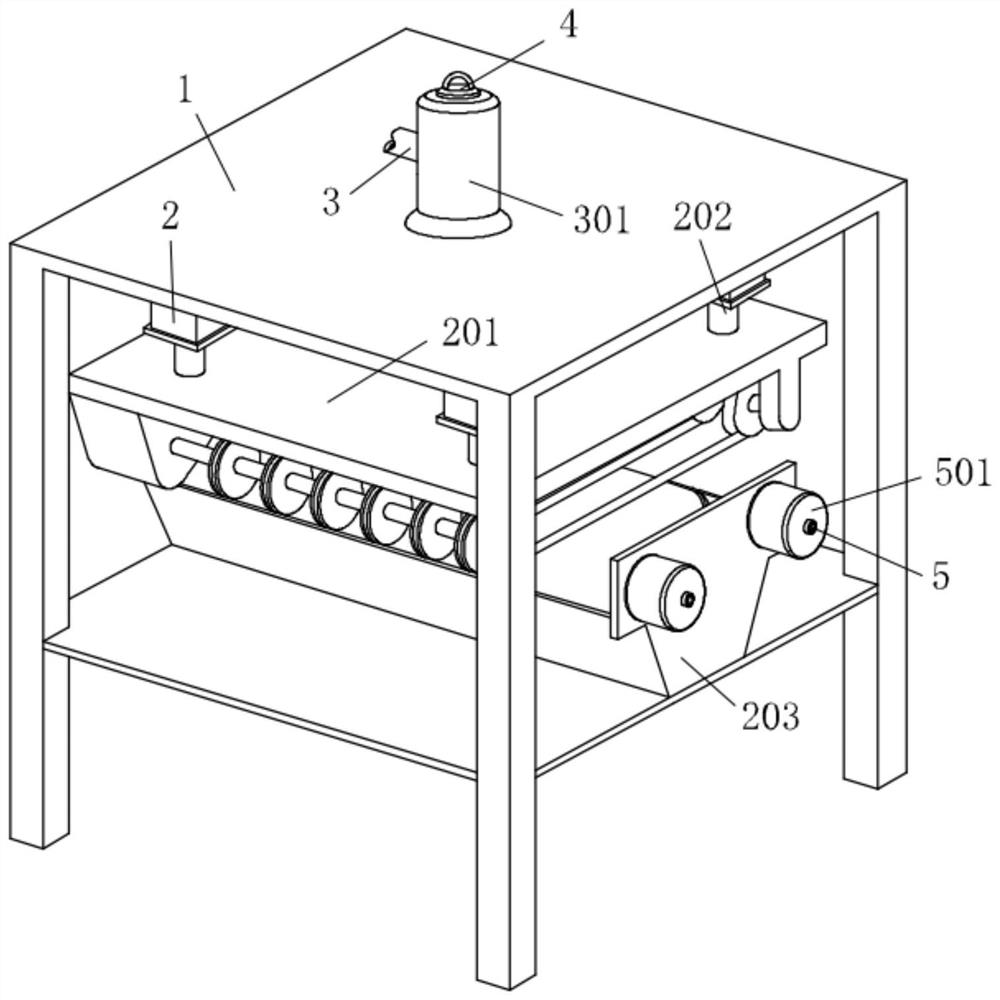

Graphite spray device and spray method thereof

PendingCN111229538ANo wasteSolve the lack of cooling capacityLiquid surface applicatorsSpraying apparatusStructural engineeringGraphite

The invention discloses a graphite spray device and a spray method thereof. The graphite spray device comprises a rack arranged at one side of a forging press machine, a movable frame movably arrangedon the rack, a lifting frame with one end part which is slidably arranged on the movable frame in the vertical direction, and a spray bucket fixedly arranged on the other end part of the lifting frame and used for storing colloidal graphite, wherein the opening of the spray bucket is upward; a plurality of nozzles communicating with an inner cavity of the spray bucket are formed in the bottom ofthe spray bucket; a first drive mechanism moving the movable frame to / out of a forging station of the forging press machine is arranged between the movable frame and the rack; and a second drive mechanism driving the lifting frame to lift is arranged between the lifting frame and the movable frame. The graphite spray device is capable of improving a spray effect for the colloidal graphite, free from causing the waste of the colloidal graphite, and capable of effectively protecting an environment.

Owner:吴鉴鸿

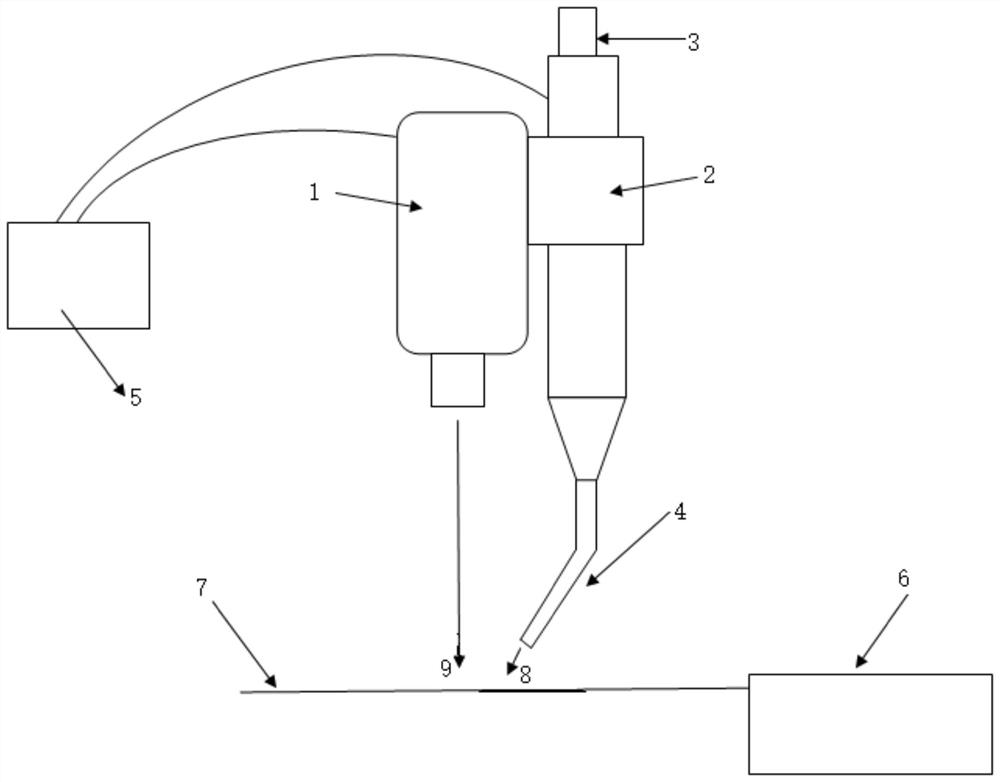

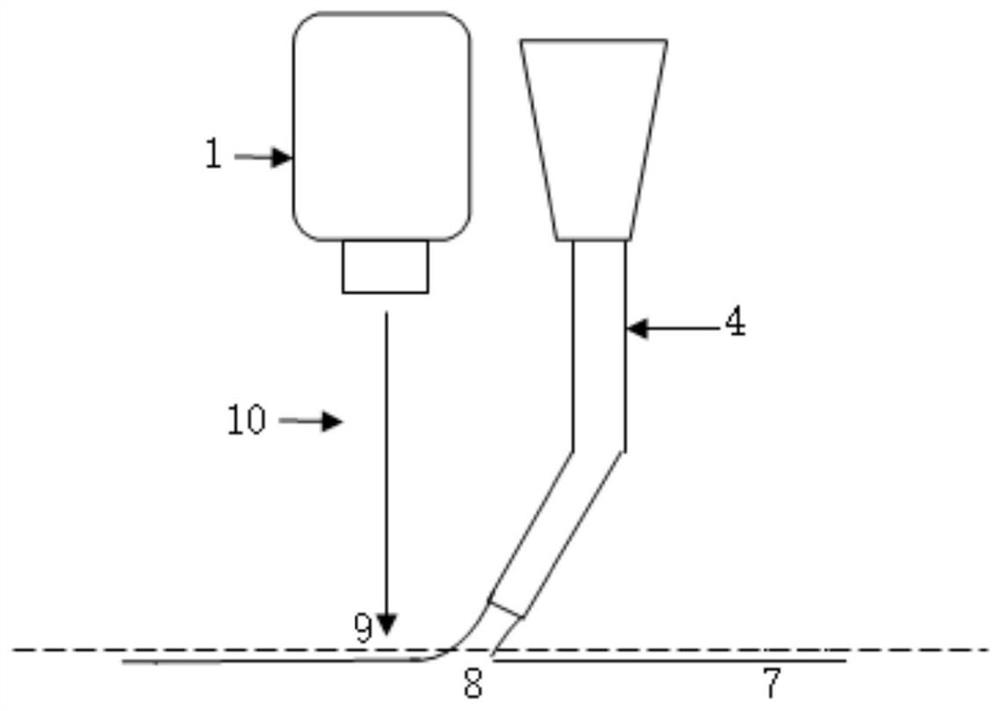

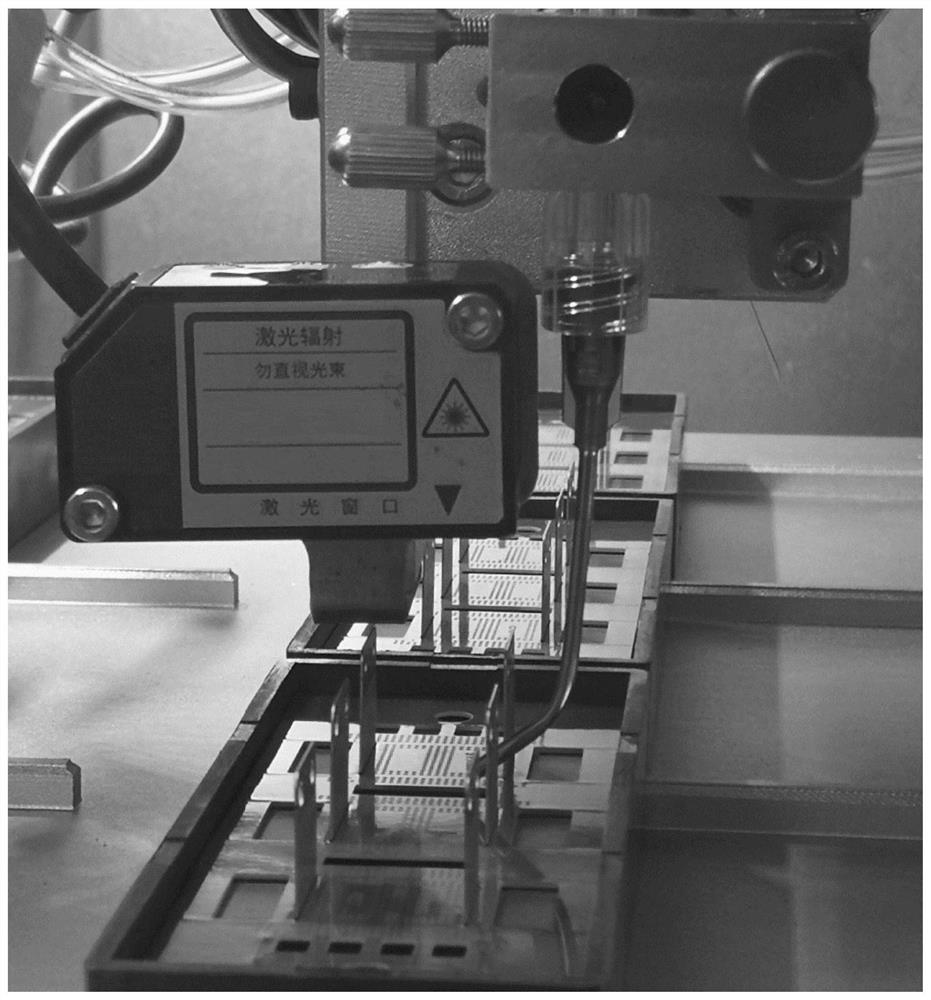

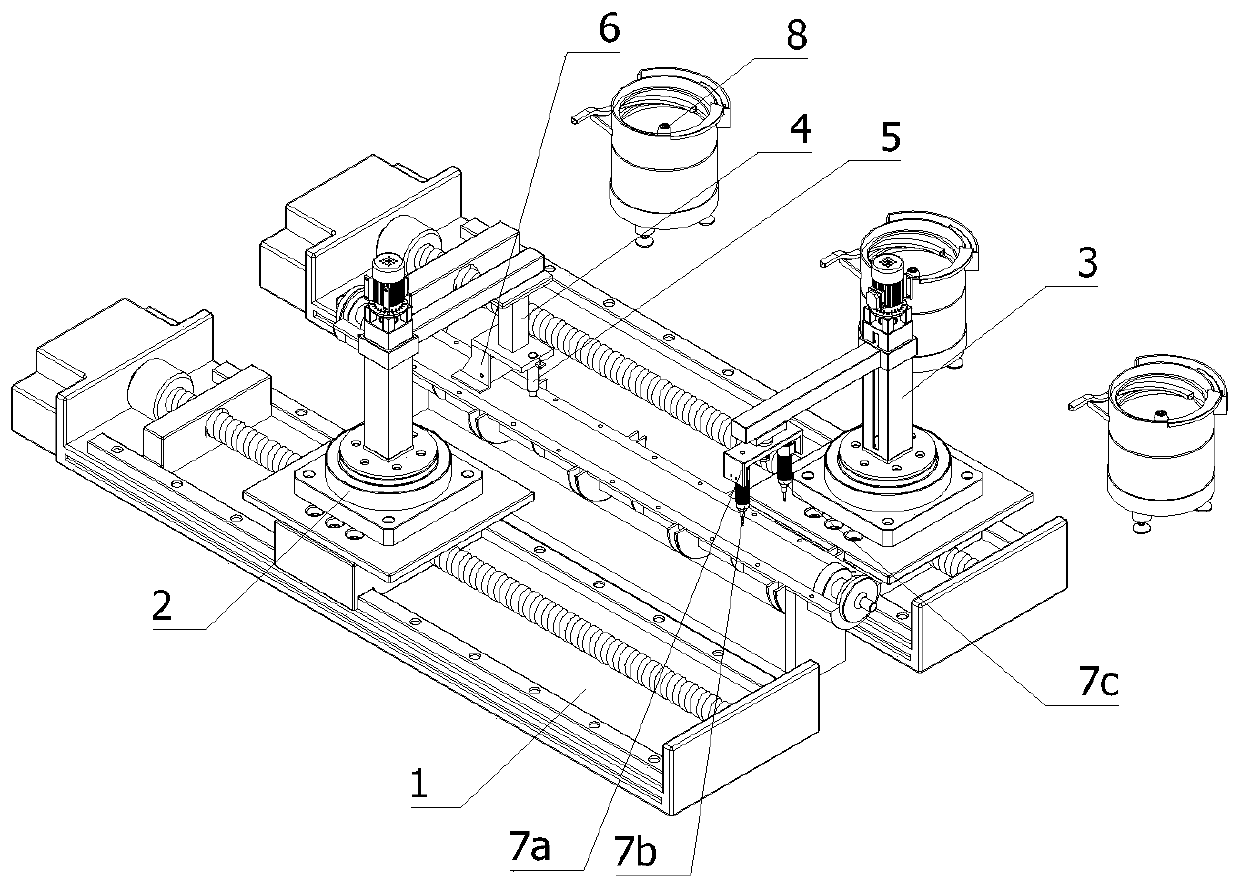

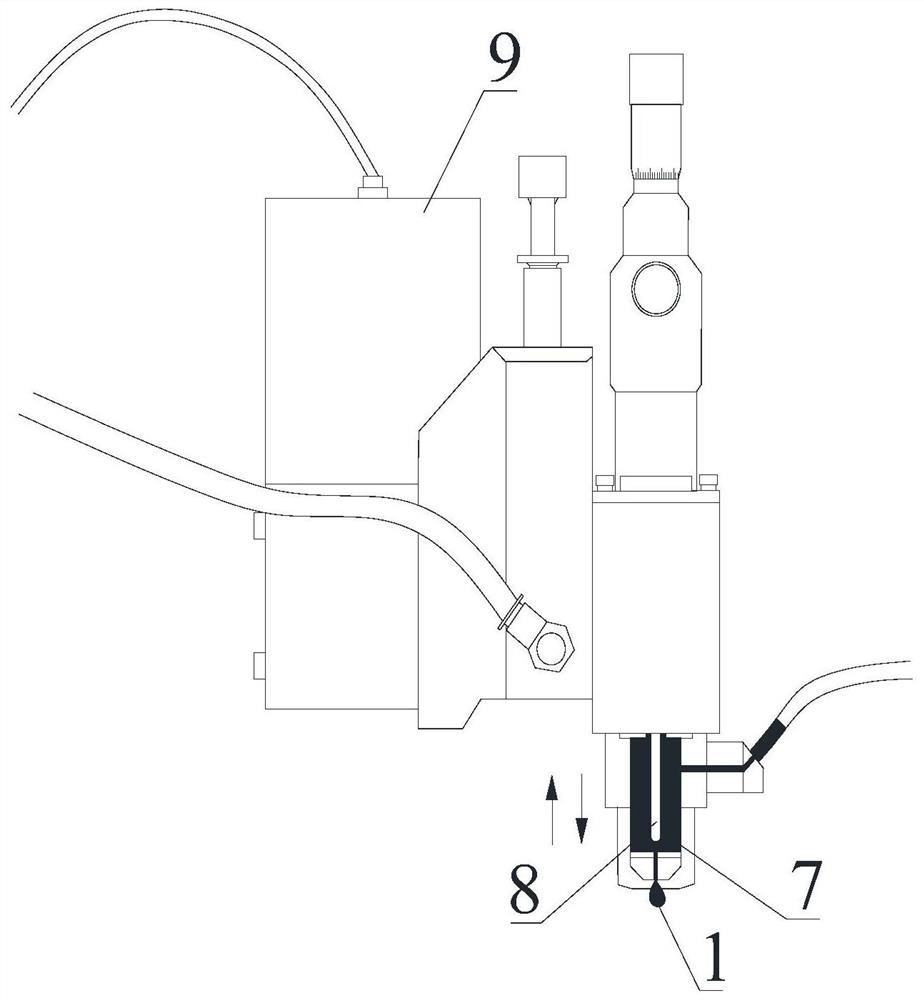

Automatic liquid level glue injection detection device and automatic liquid level glue injection method

PendingCN113917950ALow costSimple structureLevel controlMachines/enginesFluid controlControl engineering

The invention discloses an automatic liquid level glue injection detection device and an automatic liquid level glue injection method, and belongs to the technical field of automatic fluid control. A control unit, a laser height measuring probe, a switch valve and an inclined glue injection head are combined, so that the glue injection liquid level height is accurately controlled in a simple and convenient manner; the switch valve is used, the cost is low, the structure is simple, blockage is not prone to occurring, a metering pump with a complex and expensive structure is not used, and the control effect similar to that of the metering pump can be achieved. The device is simple in structure, easy to manufacture, good in stability, high in liquid level control precision, easy and convenient to use and high in efficiency, can achieve the effect similar to that of a metering pump, is suitable for various automatic glue injection schemes under the background of automation popularization, and has wide industrial application prospects.

Owner:XIAN MICROELECTRONICS TECH INST

Fuel oil pump assembly of dual-oil-tank system

ActiveCN105952557AWill not cause overflowFlexible activitiesMachines/enginesLiquid fuel feedersUltrasonic weldingFuel tank

The invention discloses a fuel oil pump assembly of a dual-oil-tank system. The fuel oil pump assembly comprises an oil storage bucket, an oil storage bucket cover, an oil return pipeline and an oil outlet pipeline. An oil pump, an oil pump connecting pipe and an oil inlet pipe are arranged in the oil storage bucket. The fuel oil pump assembly is characterized in that a shuttle valve is further arranged in the oil storage bucket and is arranged on the oil return pipeline to control on-off of the oil return pipeline; fuel oil pumped in the oil inlet pipe is in drive fit with the driving end of the shuttle valve, the oil inlet pipe is fixed in the oil storage bucket in an ultrasonic welding manner, and the oil inlet pipe and the shuttle valve are fixed in an ultrasonic welding manner; the oil pump connecting pipe and the shuttle valve are fixedly connected with the oil storage bucket cover through a buckle structure after being subjected to ultrasonic welding, and the oil pump is mounted in the oil pump connecting pipe and fixed in the oil storage bucket through the buckle structure on the oil storage bucket cover; and a check valve is arranged at an oil inlet hole. The fuel oil pump assembly is reasonable in structure, buckle connecting and fixing are adopted, the structure is simple, assembly is easy, and the umbrella-shaped check valve is flexible in movement and good in check sealing performance.

Owner:ZHEJIANG JINJIA AUTOMOBILE PARTS

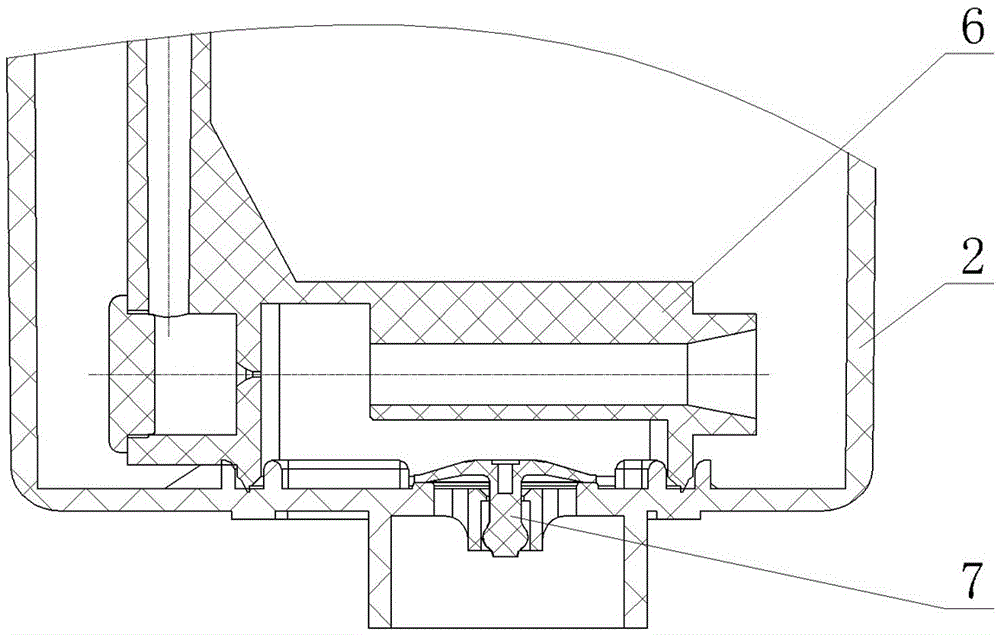

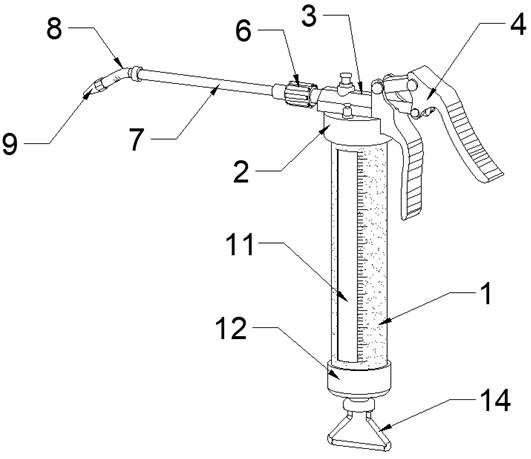

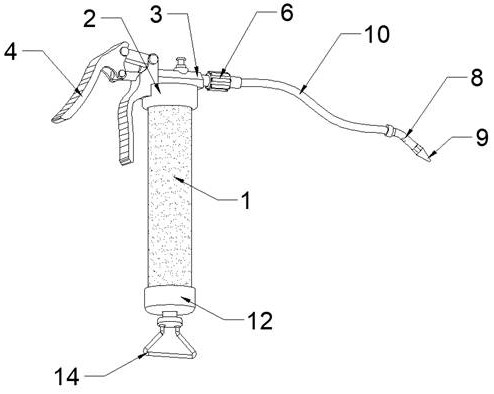

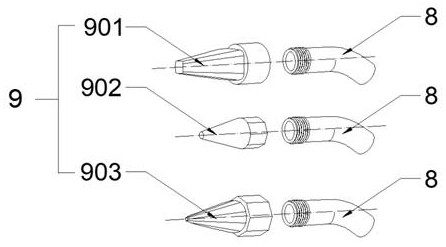

Grease gun capable of achieving multi-angle filling for automobile maintenance

ActiveCN113375030AWill not cause overflowImprove sealingManual lubricationConduits/junctionsMechanical engineeringAutomotive engineering

The invention discloses a grease gun capable of achieving multi-angle filling for automobile maintenance, which comprises a gun body, the upper end of the gun body is in threaded connection with an upper sealing cover, and a grease outlet mechanism is arranged at the upper end of the upper sealing cover; an observation window which is arranged at the front end of the outer surface of the gun body, and a dial for observation is arranged on the right side of the observation window made of a transparent material; a lower sealing cover which is installed at the lower end of the gun body in a threaded connection mode, and a control mechanism is installed in the gun body; and the grease outlet mechanism comprises a gun head, a grip and a grease outlet valve. According to the grease gun capable of achieving multi-angle filling and used for the automobile maintenance provided by the invention, a grease filling head can be replaced according to specific use requirements, gas in grease can be emptied after the grease filling work is completed, the sealing effect in the grease gun is good, grease overflowing cannot be caused, meanwhile, the angle of the grease filling head can be rotatably adjusted, and multi-angle filling is facilitated.

Owner:WULIAN COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

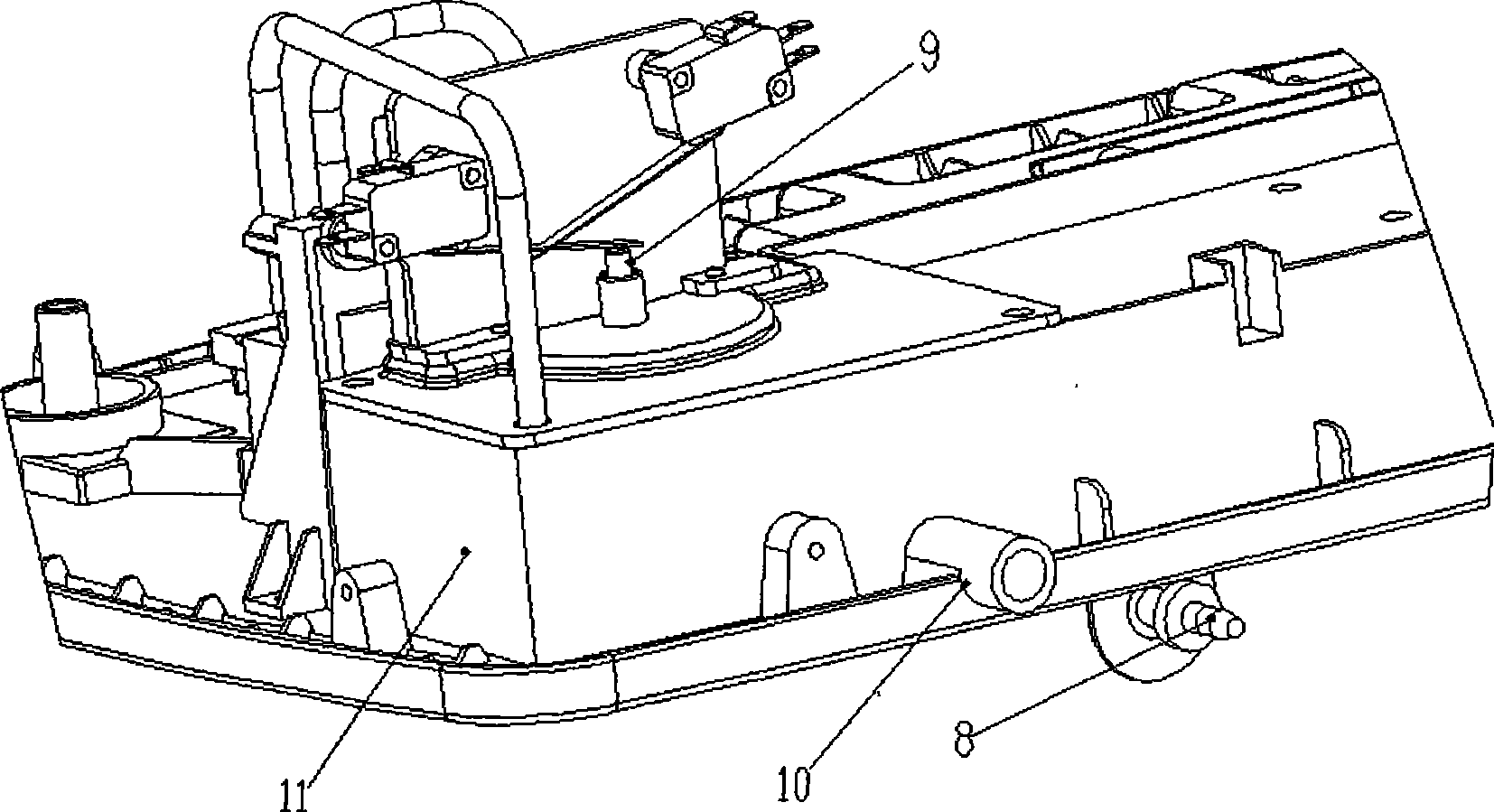

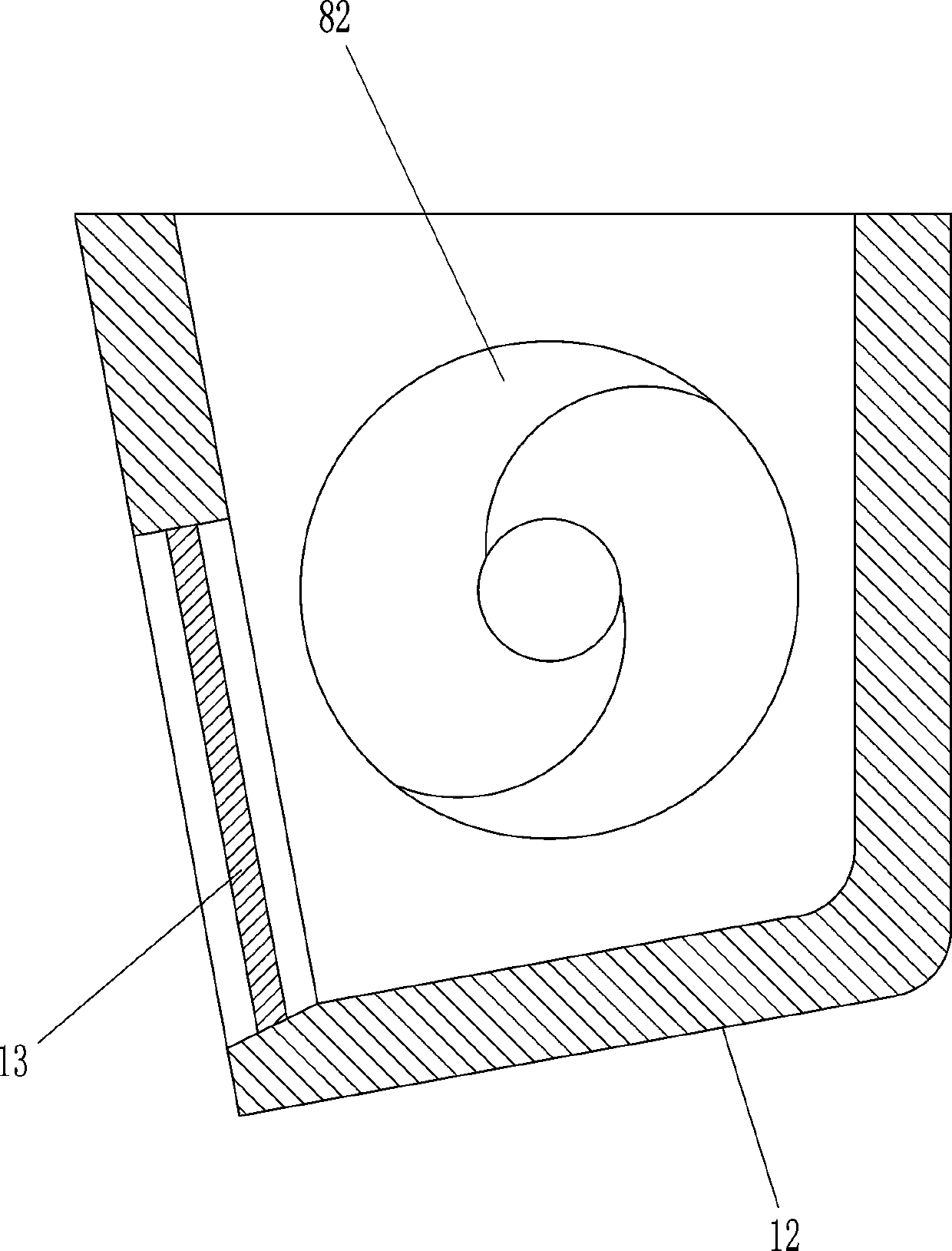

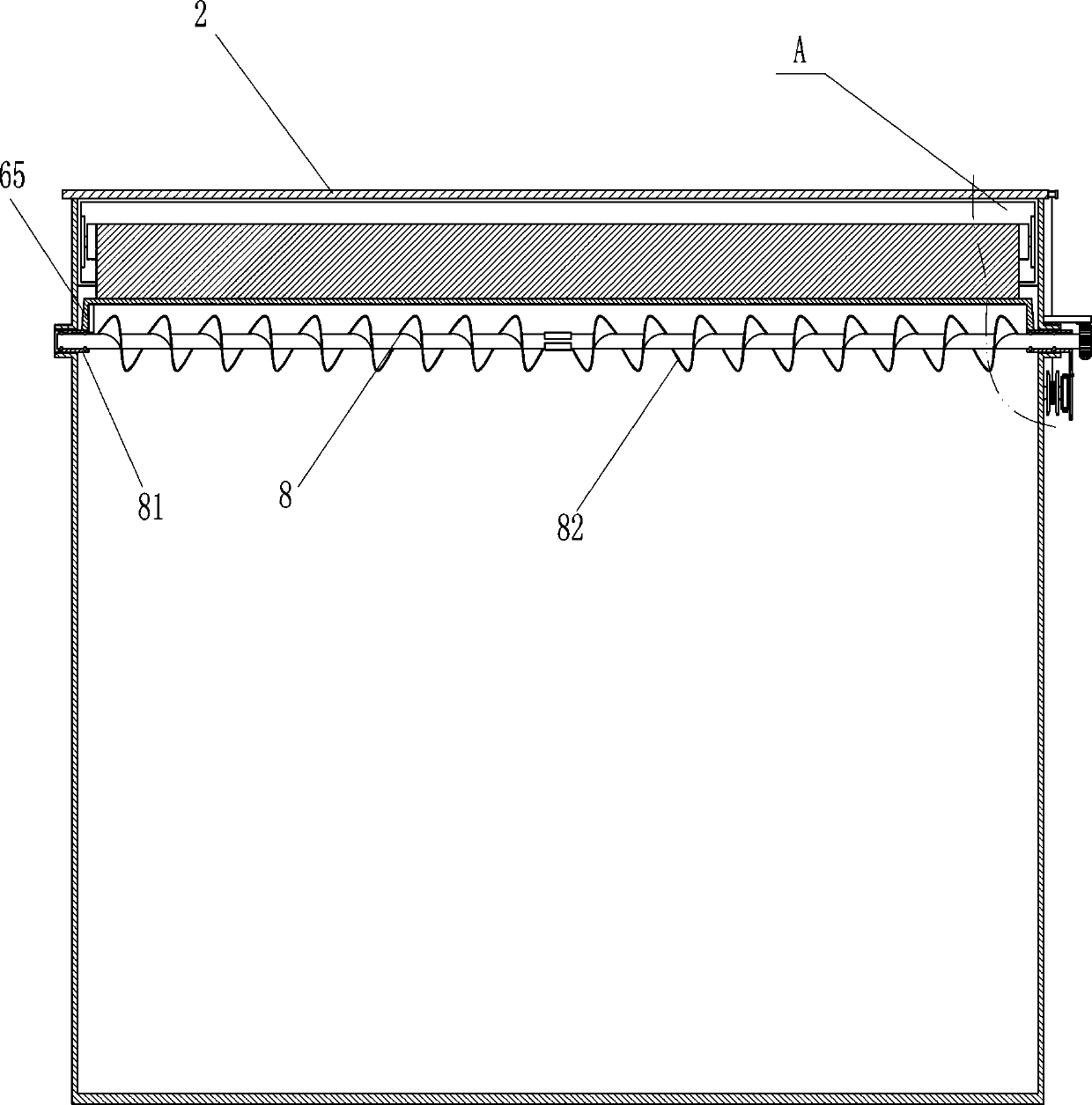

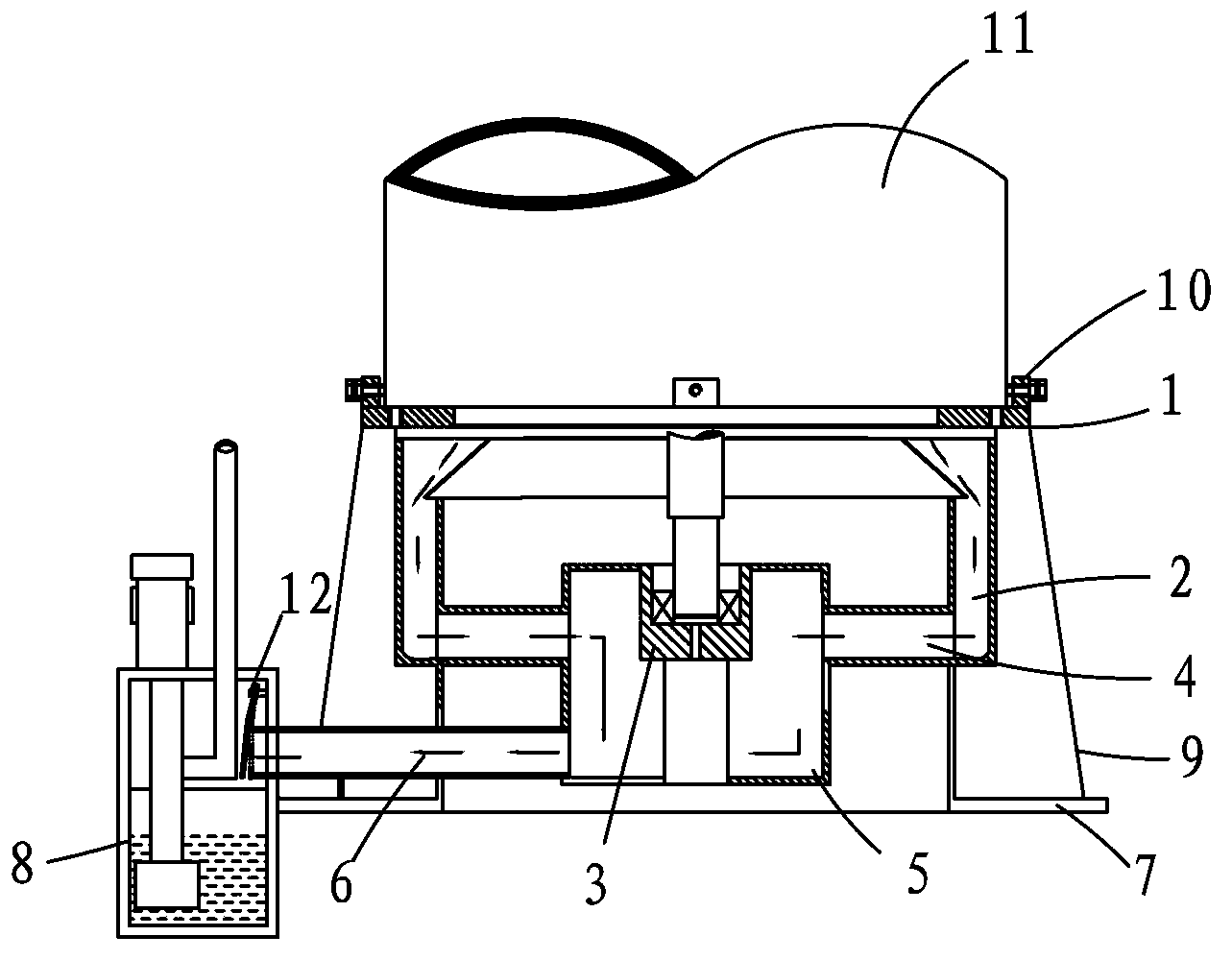

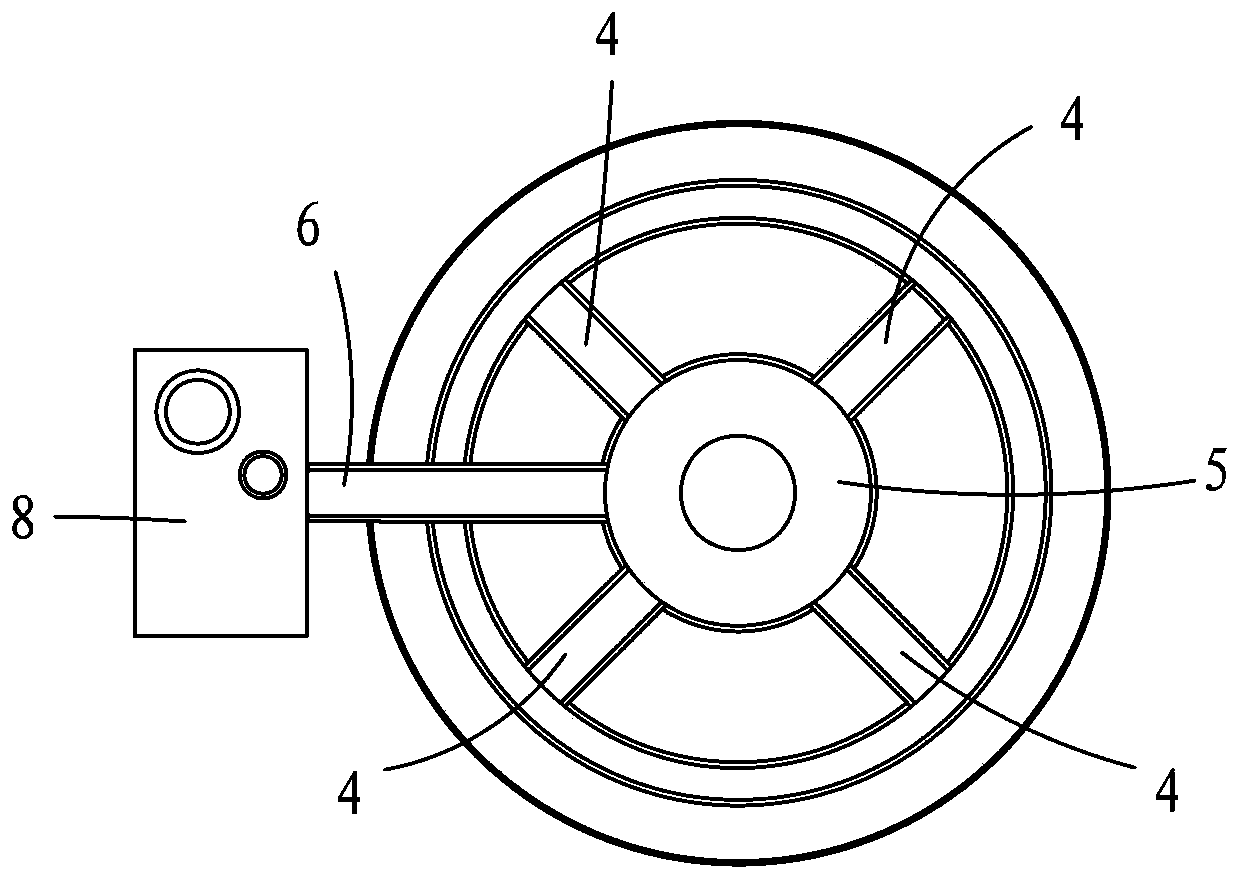

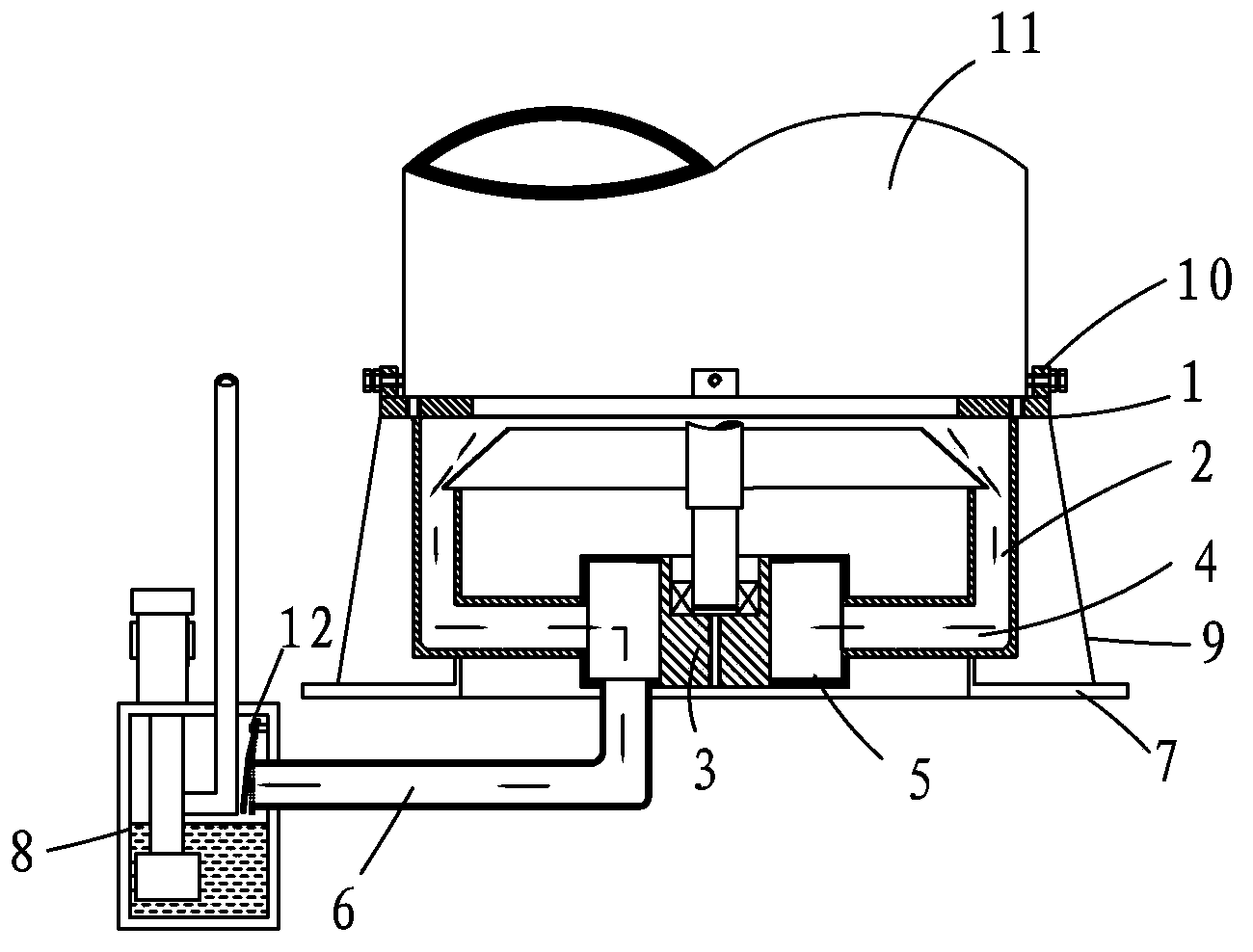

Improved base device of marine slice ice machine

ActiveCN103411361AWill not cause backflowWill not cause overflowLighting and heating apparatusIce productionEngineeringWater flow

The invention discloses an improved base device of a marine slice ice machine. The improved base device comprises a base upper plate, an annular water receiving groove, a bearing base, water guiding pipes, an auxiliary water box, a water outlet pipe and a base lower plate, wherein the annular water receiving groove is positioned below the base upper plate, and an outer cylinder of the annular water receiving groove is connected with the base upper plate; the auxiliary water box is arranged below the annular water receiving groove, and the annular water receiving groove and the auxiliary water box are communicated through three or more than three water guiding pipes, and the water guiding pipes are uniformly arranged; the water outlet of the auxiliary water box is connected with the water outlet pipe, and the bearing base is connected above the middle of the auxiliary water box. The improved base device provided by the invention has the advantages that stream is avoided leaking, meanwhile, the safe and reliable operation of an ice manufacturing water circulating system is guaranteed.

Owner:FUJIAN SHENGRONG MARINE EQUIP MFG

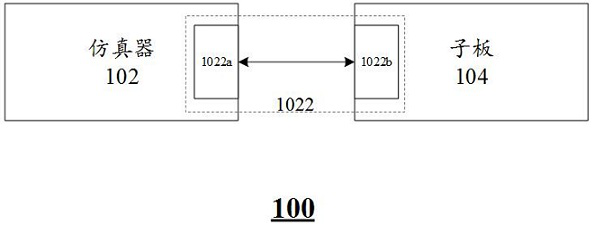

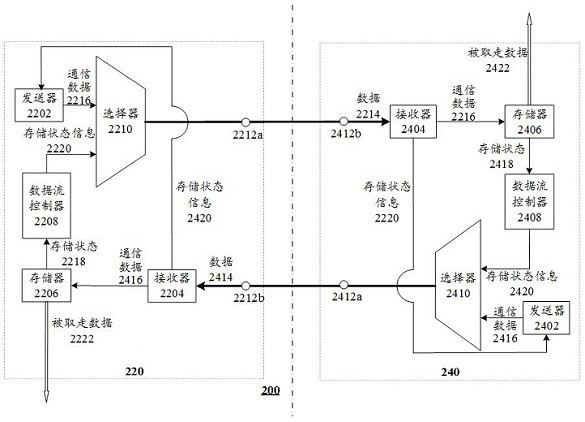

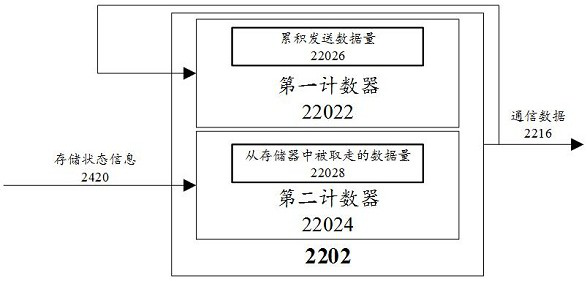

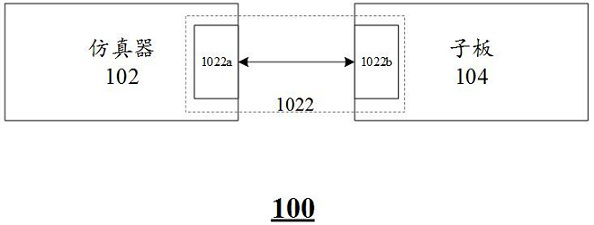

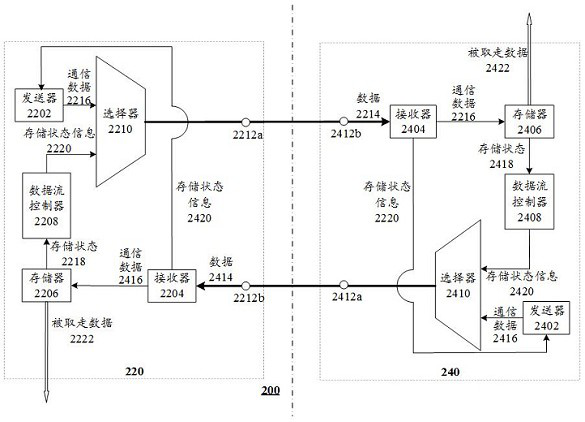

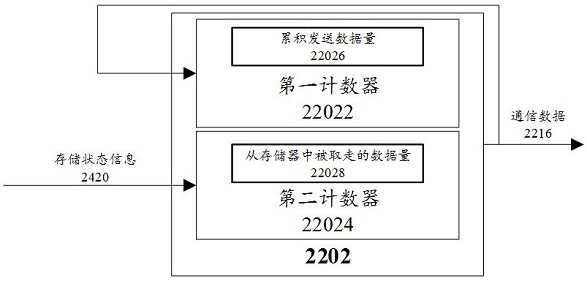

Interface device and method for serial communication and electronic equipment

ActiveCN112035391AWill not cause overflowReduce consumptionElectric digital data processingEngineeringStorage cell

The invention provides an interface device and method for serial communication and electronic equipment. The interface device comprises: a sending unit used for sending communication data to an opposite interface device corresponding to the interface device, wherein the opposite interface device comprises a storage unit used for storing the communication data; and a receiving unit electrically coupled to the transmitting unit and configured to receive input information from the opposite interface device, the input information including storage state information of a storage unit of the opposite interface device, the transmitting unit being configured to: determine the expected data volume of the communication data sent to the opposite interface device according to the data volume of the sent communication data and the storage state information of the storage unit of the opposite interface device.

Owner:芯华章科技股份有限公司

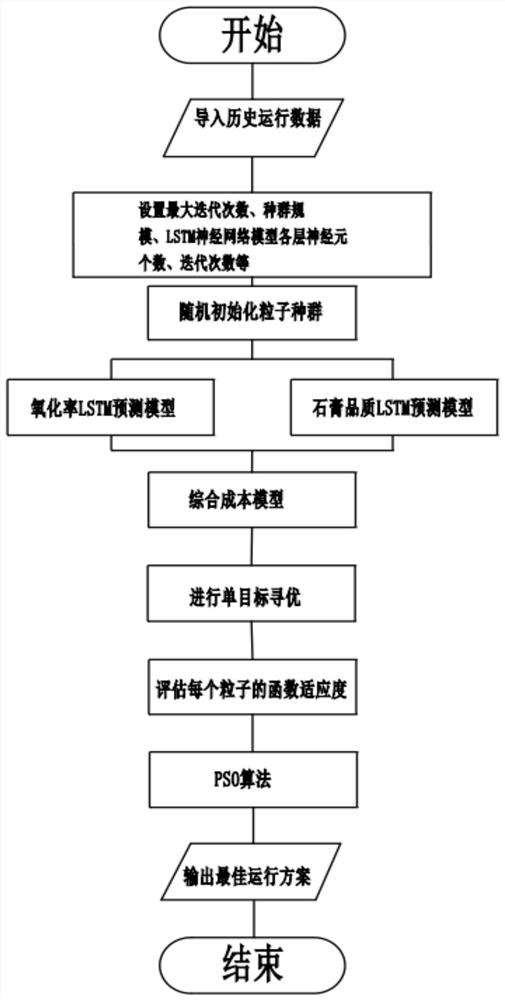

Oxidation fan operation optimization algorithm based on particle swarm optimization

PendingCN114444391AReduce environmental risksReduce energy consumptionGas treatmentDispersed particle separationGypsumProcess engineering

The invention relates to the technical field of flue gas desulfurization of a coal-fired power plant, and particularly discloses an oxidation fan operation optimization algorithm based on particle swarm optimization, which comprises the following steps: S1, finding out influence factors influencing the operation efficiency of an oxidation fan according to historical operation data, and establishing a data set, S2, carrying out correlation preprocessing on the data set in S1 by adopting a Pearson correlation analysis method, s3, selecting operation parameters related to the oxidation rate and the gypsum quality as input, taking the oxidation rate and the gypsum quality as output, and establishing an oxidation rate LSTM prediction model and a gypsum quality LSTM prediction model, S4, taking the oxidation rate and the field operation parameters as references, establishing a mechanism model, obtaining a comprehensive cost model of the desulfurization system under various working conditions, and calculating the comprehensive cost of the desulfurization system. S5, performing single-target optimization on the oxidation air volume by adopting a particle swarm optimization algorithm on the basis of the LSTM prediction model, the gypsum quality LSTM prediction model and the desulfurization system comprehensive cost model; and S6, searching the optimal oxidation air volume and providing the optimal oxidation air volume to an oxidation fan control system.

Owner:華能重慶珞わん発電有限責任公司

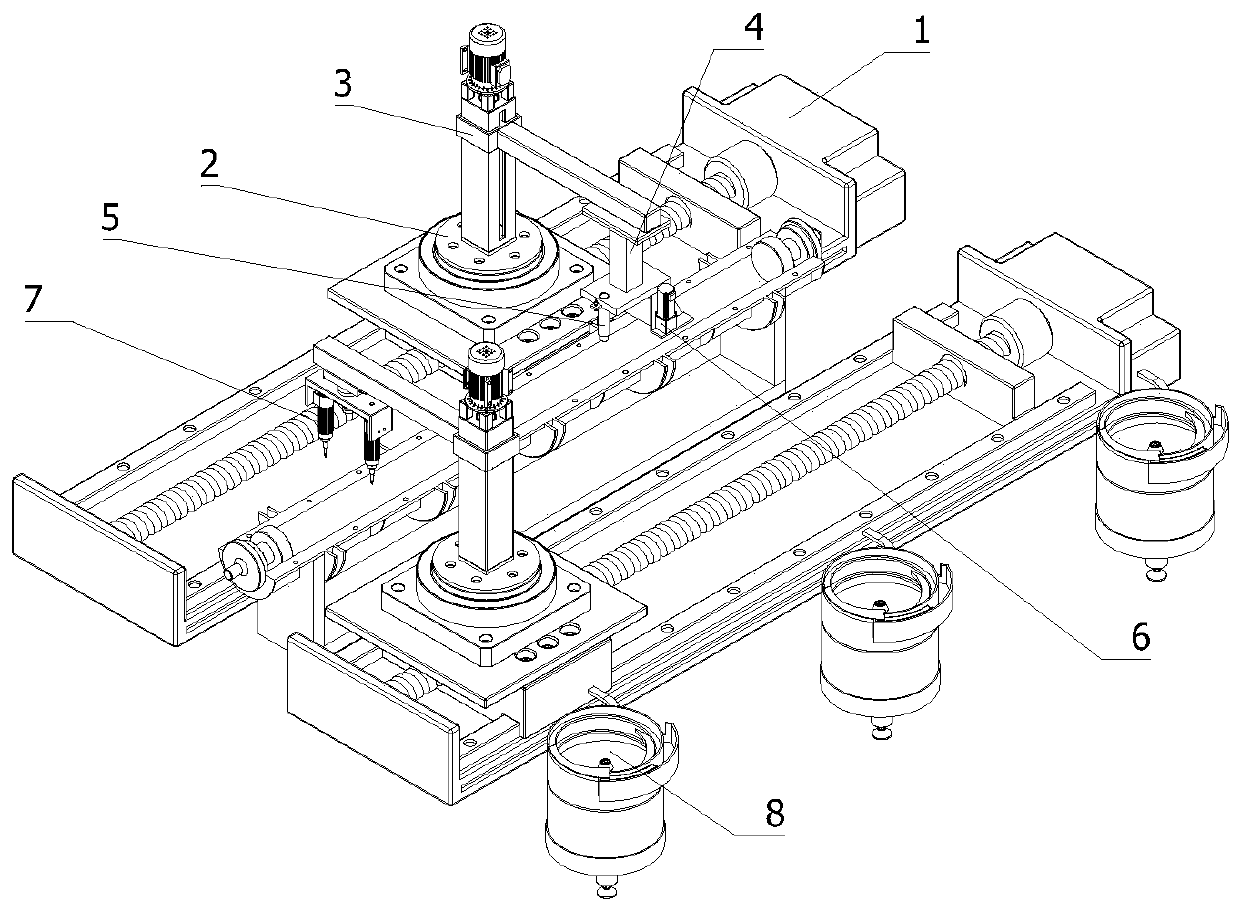

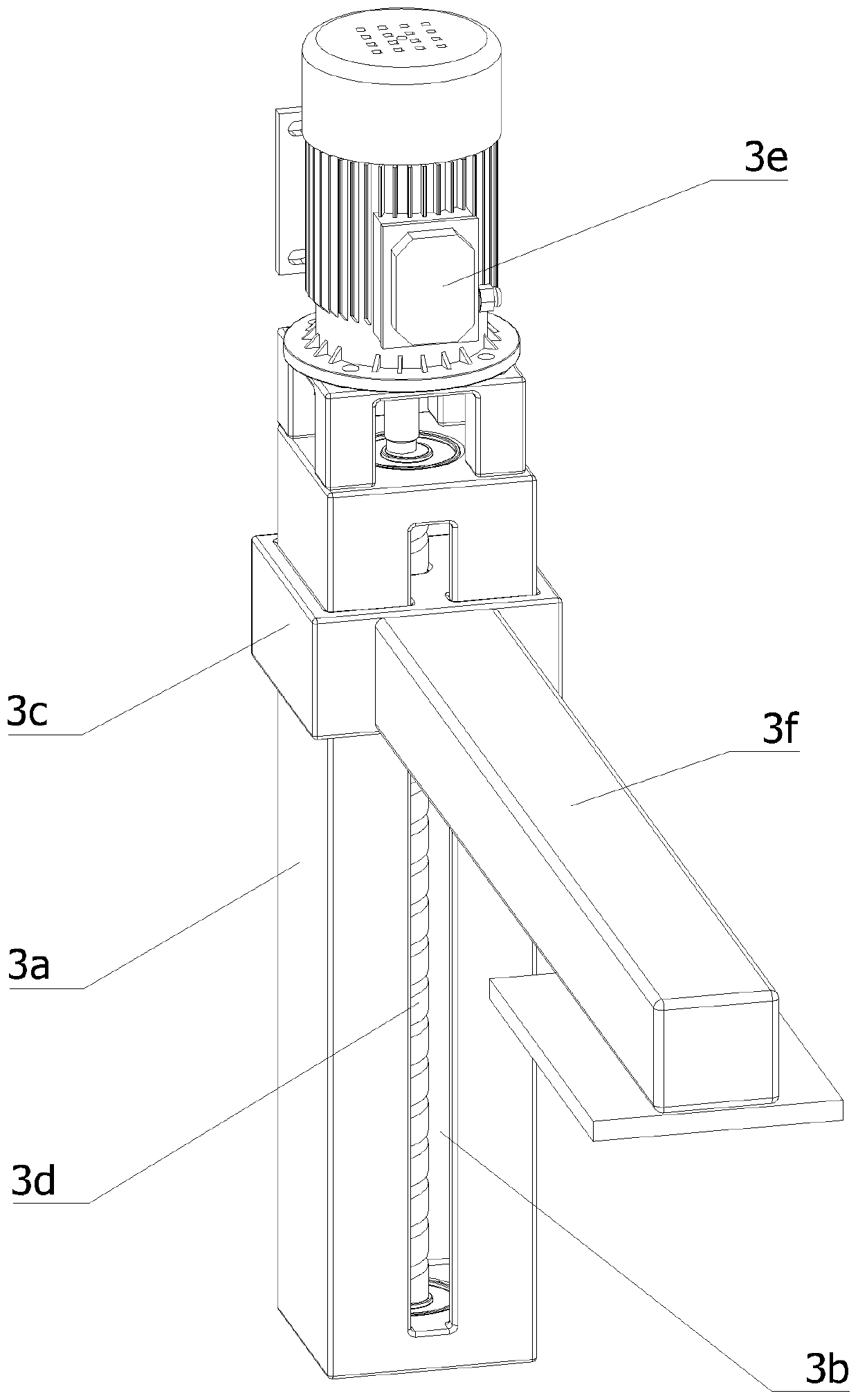

Automatic filling and cleaning device for cement telegraph pole

InactiveCN111516133AEasy to pick up nearbyUniform injectionMouldsFeeding arrangmentsMechanical engineeringIndustrial engineering

The invention relates to the technical field of cement telegraph pole production, in particular to an automatic filling and cleaning device for a cement telegraph pole. The automatic filling and cleaning device comprises a pair of linear driving mechanisms, a pair of rotating mechanisms, a pair of lifting mechanisms, a hanging bracket, a cement pouring mechanism, a cleaning mechanism, an automaticbolt assembling mechanism, an automatic bolt loading mechanism and a controller. The pair of linear driving mechanisms is symmetrically arranged on two sides of a lower die of the cement telegraph pole, the pair of rotating mechanisms is separately arranged at the working ends of the pair of linear driving mechanisms, the pair of lifting mechanisms is separately arranged on the pair of rotating mechanisms, the hanging bracket is mounted at the working end of one of the pair of lifting mechanisms, the cement pouring mechanism and the cleaning mechanism are arranged on the hanging bracket and the cement pouring mechanism is closer to an advancing direction compared with the cleaning mechanism, the automatic bolt assembling mechanism is mounted at the working end of the other lifting mechanism, and the automatic bolt loading mechanism is arranged on one side of the lifting mechanism where the automatic bolt assembling mechanism is arranged. According to the scheme, the manpower is saved,the production efficiency is improved greatly, and the automatic filling and cleaning device is precise to position.

Owner:张恒

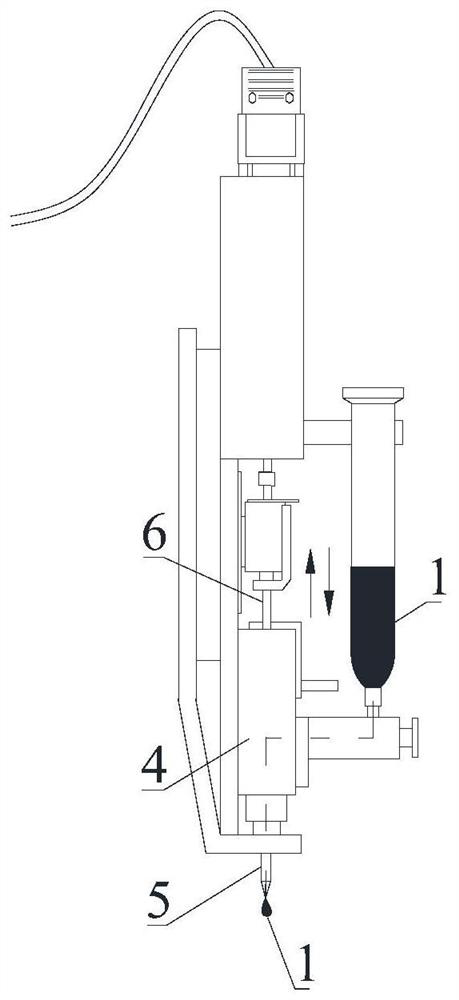

Process for coating fluorescent glue layer on surface of LED chip

InactiveCN112156950AControl the amount of glue dipped in a single timeWill not cause overflowLiquid surface applicatorsSemiconductor/solid-state device manufacturingFluorescenceEngineering

The invention discloses a process for coating a fluorescent glue layer on the surface of an LED chip. The process comprises a mounting step; a glue preparation step; a feeding step; a glue dipping step; a glue supplementing step; and a dispensing step. After the dispensing step is completed, the working cycle of the glue dipping step, the glue supplementing step and the dispensing step is repeatedfor multiple times until the surface of the LED chip is completely coated with the fluorescent glue layer. According to the process, coating is carried out in a multi-time dispensing manner, so thatthe coating amount of each chip can be accurately controlled, the situations of glue overflow and glue waste are avoided, and the cost is better saved; and by accurately controlling the amount of gluecoated on the LED chip, the consistency of the coating amounts of different LED lamp beads is ensured, so that the consistency of mixed color light of the LED lamp beads is ensured, and the standardization degree of large-batch products is improved.

Owner:GUANGZHOU JUHONG OPTOELECTRONICS

Automatic cleaning device for eccentric separators

The invention discloses an automatic cleaning device for eccentric separators. The automatic cleaning device comprises a rotor drum shell. A variable-frequency gear motor is arranged in the rotor drum shell and is eccentrically connected with a cam by a coupling, and a rotary shaft of a rotor drum is connected with the cam; an opening is formed in the upper end of the rotor drum shell, a circle of liquid barrier is arranged at the edge of the opening, a support is fixedly mounted on a side wall of the opening, a water pipe with a pneumatic ball valve is fixedly mounted on the support and forms a cantilever, the tail end of the water pipe is positioned in the rotor drum, eight spraying holes are formed in the side walls of the water pipe and are divided into an upper group and a lower group, each group comprises four corresponding spraying holes, and the spraying holes in each group are circumferentially uniformly distributed on the side walls of the water pipe. Compared with an existing manual flushing mode, the automatic cleaning device has the advantages that the eccentric separators can be automatically cleaned by the aid of the flushing pipe additionally arranged on the side wall of the rotor drum; the liquid barrier can prevent liquid from being splashed on human bodies; a protection effect can be realized by the ball valve on the water pipe, so that the liquid can be prevented from spilling.

Owner:CHONGQING CHENGSHUO TECH

Shower room floor drainage structure

InactiveCN110206266AWill not cause overflowPrevent overflowSewerage structuresBuilding insulationsAgricultural engineeringShower

The invention discloses a shower room surface drainage structure, which includes a waterproof floor body and a water retaining strip arranged on the outer side of the waterproof floor body. Each unitplate includes a first splicing structure arranged on the front side of one side of the unit plate and a second splicing structure arranged on the back side of the other side of the unit late, the unit plate is made of an SMC, a drainage ditch groove is formed in the front side of the unit plate, the depth of the drainage ditch groove is less than the thickness of the unit plate, drainage ditch grooves of each rank unit plates communicate in turn, drainage ditch grooves of each row unit plates are parallel to one another, a drainage groove is formed in the water retaining strip, the drainage groove communicates with each rank drainage ditch grooves, one of the unit plates is provided with a floor drain mounting hole corresponding to a drainage opening of a shower room, the floor drain mounting hole communicates with the drainage ditch groove on the unit plate, each unit plate is detachably provided with a cover plate for closing the drainage ditch groove correspondingly, and the coverplate is provided with a leakage hole communicating with the drainage ditch groove.

Owner:泉州昌荣贸易有限公司

Wafer seat

InactiveCN104576550AImprove adhesionWill not cause overflowSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The invention discloses a wafer seat which comprises a wafer seat main body, wherein an annular seat is arranged in the middle of the upper end surface of the wafer seat main body and is arranged in a way of projecting the upper end surface of the wafer seat, and an annular groove is correspondingly formed in the wafer seat; a plurality of convex sticking points are arranged on the end surface of the wafer seat main body in the annular seat, and the arrangement height of each convex sticking point is flush with that of the annular seat. By the mode, the wafer seat can increase the adhesion degree between the wafer and the wafer seat and enable redundant tin liquid flowing out during wafer welding to flow along the annular groove so as not to cause overflow.

Owner:WUXI KENUODA ELECTRONICS

CT scanning device and method for sediment pore structure in hydrate generation and decomposition processes

InactiveCN111337523AUniform responseEasy to splitMaterial analysis using wave/particle radiationSoil scienceImage segmentation

The invention provides a CT scanning device and method for a sediment pore structure in hydrate generation and decomposition processes, and the CT scanning device comprises a steel cylinder, a barometer, a three-way connecting valve, a gas communicating pipe, a sediment bin, a sediment filling groove, a spring and a breathable gasket. According to the technical scheme, the difference between the density of the xenon hydrate and the density of water is large, and therefore CT image segmentation is easy. And the three-way connecting valve and the gas communicating pipe are combined for use, so xenon can enter the sediment loading tank from top to bottom, and hydrate reacts uniformly in the generation process. The combination of the spring and the sediment loading groove can control the movement of the sediment loading groove caused by self-weight change in the hydrate generation process, and alleviate the impact and vibration of the sediment loading groove. The breathable gaskets are distributed on the upper portion and the lower portion of the sediment loading groove, ventilation can be achieved, sediment falling and overflowing cannot be caused, and the requirement for uniformity of xenon in the hydrate generation process is met.

Owner:OCEAN UNIV OF CHINA

Interface device, method, electronic device for serial communication

ActiveCN112035391BWill not cause overflowReduce consumptionElectric digital data processingEngineeringStorage cell

The present disclosure provides an interface device, method and electronic equipment for serial communication. The interface device includes: a sending unit, configured to send communication data to the opposite interface device corresponding to the interface device, wherein the opposite interface device includes a storage unit for storing the communication data; A receiving unit electrically coupled to the unit, configured to receive input information from the opposite interface device, wherein the input information includes storage state information of a storage unit of the opposite interface device, wherein the sending unit is configured The method is: according to the data volume of the sent communication data and the storage status information of the storage unit of the opposite interface device, determine the expected data volume of the communication data to be sent to the opposite interface device.

Owner:芯华章科技股份有限公司

Multi-section slicing machine for monocrystalline silicon processing

ActiveCN114407211AEasy to hold and placeReduce wearFine working devicesSilicon chipMonocrystalline silicon

The invention relates to the technical field of monocrystalline silicon slicing, in particular to a multi-section slicing machine for monocrystalline silicon processing, which comprises a fixing frame, a mounting mechanism is mounted on the fixing frame, a spraying mechanism is mounted on the fixing frame, a filtering mechanism is mounted on the spraying mechanism, an abutting mechanism is mounted on the mounting mechanism, and an abutting mechanism is mounted on the abutting mechanism. A collecting mechanism is mounted in the mounting mechanism, and a pollution discharge mechanism is mounted on the collecting mechanism; the mounting mechanism and the abutting mechanism facilitate good placement and slicing work of monocrystalline silicon with different lengths, the spraying mechanism and the filtering mechanism work, better cutting of the monocrystalline silicon is facilitated, abrasion of equipment is reduced, impurities in water can be filtered, and the service life of the equipment is prolonged. And by means of the importance of the collecting mechanism and the sewage discharging mechanism, the cut silicon wafers can be collected and placed, abrasion caused by falling of the silicon wafers is reduced, and meanwhile sewage can be conveniently recycled and stored.

Owner:无锡京运通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com