Flip type garbage collection box capable of uniformly pouring garbage

A garbage collection and flip-top technology, which is applied in the field of garbage collection boxes, can solve problems affecting work efficiency and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

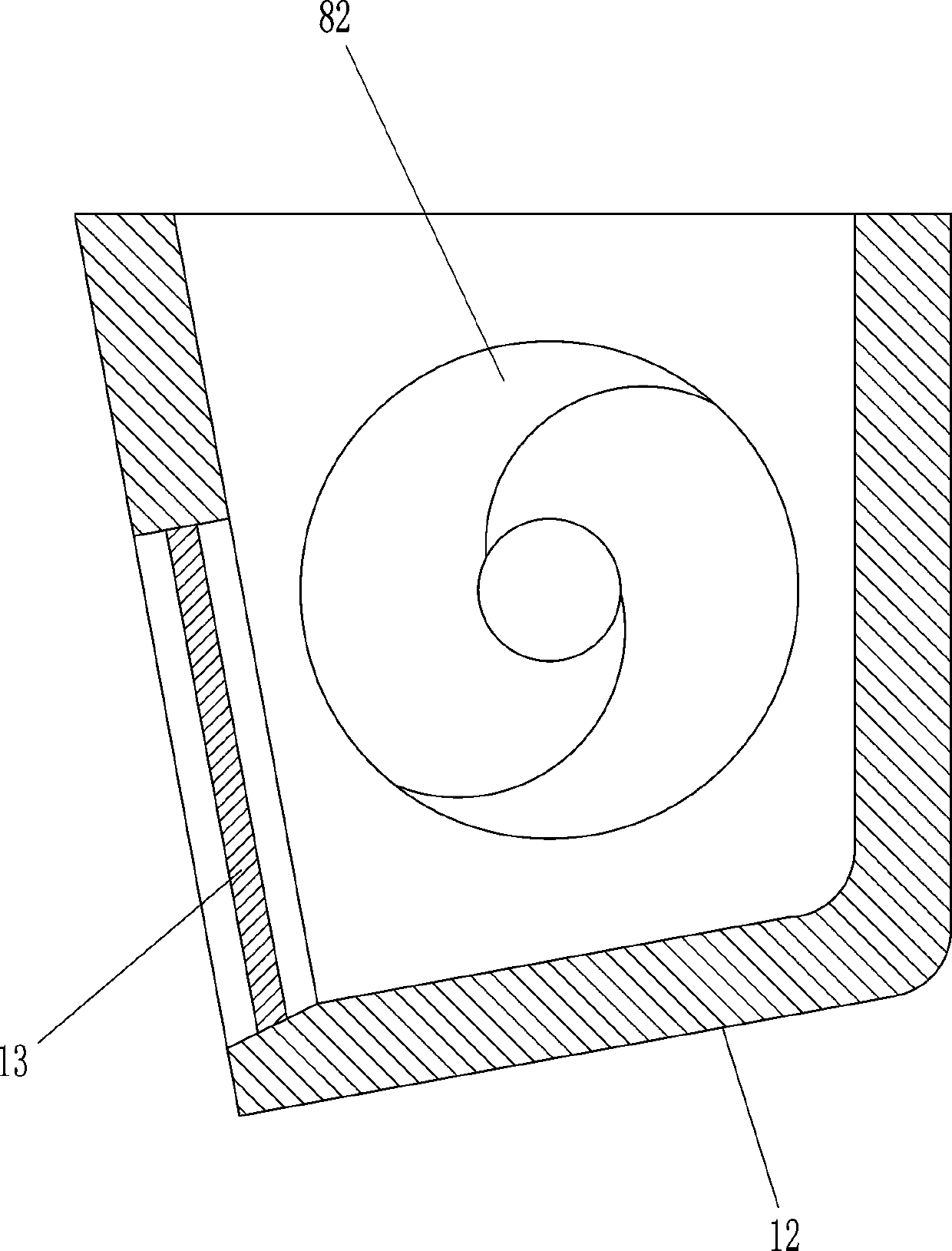

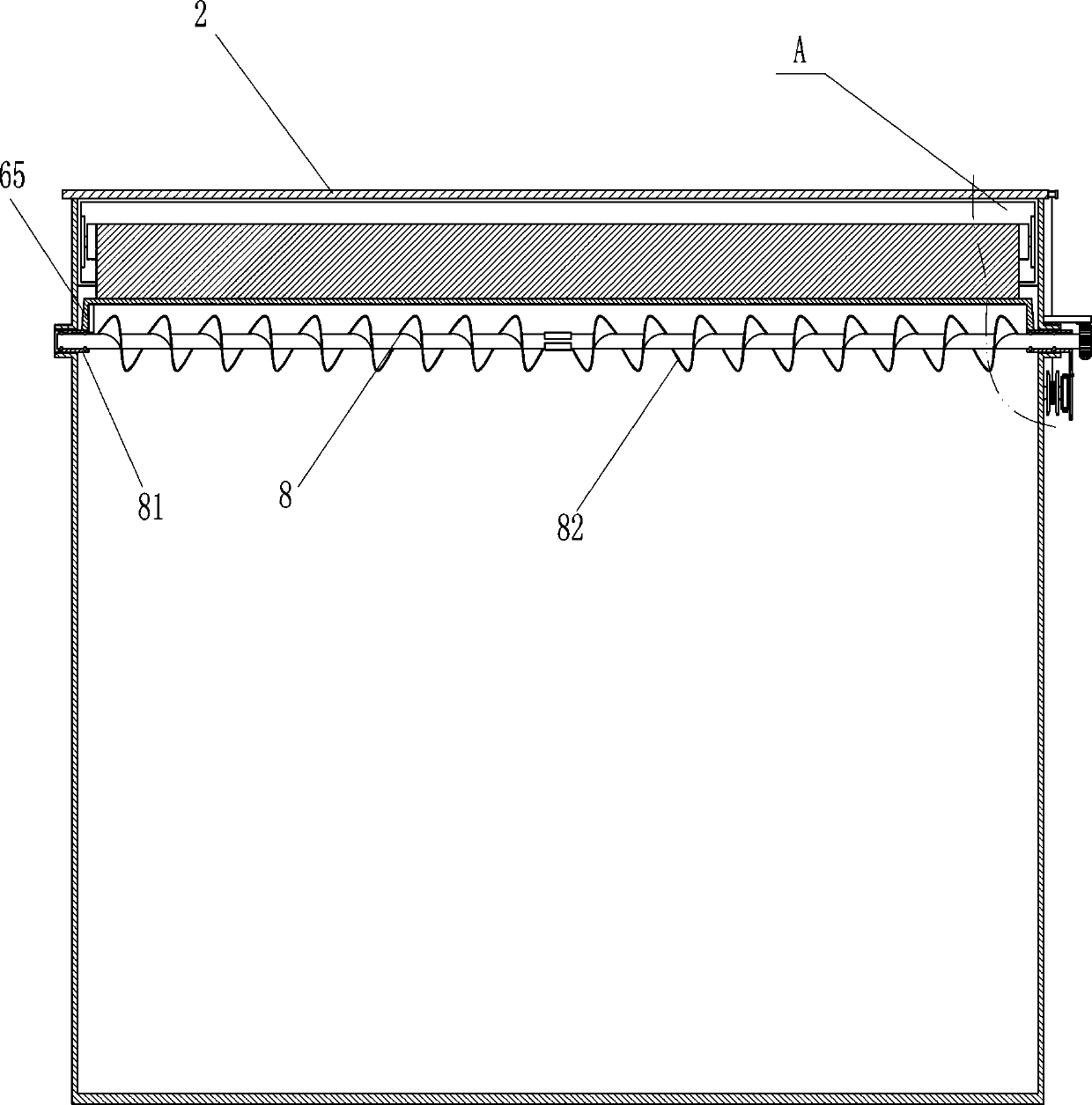

[0022] A kind of flip-top garbage collection box that can evenly dump materials, such as figure 1 As shown, it includes a garbage collection box 1 and a cover plate 2. The top of the garbage collection box 1 is hingedly connected with a cover plate 2. The cover plate 2 is connected to the garbage collection box 1 through a hinged connection. The cover plate 2 is used to cover the garbage. The top of the collection box 1 also includes a cylinder 3, a placement seat 4, a connecting rod 5, a flow guiding device 6 and a material distribution assembly 8, and the front and rear walls of the garbage collection box 1 are rotatably equipped with a cylinder 3 and a telescopic rod of the cylinder 3. It is hingedly connected with the bottom of the cover plate 2, and the tail end of the cover plate 2 is hingedly connected with a connecting rod 5. There are two connecting rods 5, and both connecting rods 5 are connected to the middle part of the tail end of the cover plate 2. The outer wall ...

Embodiment 2

[0029] Such as figure 1 and image 3 As shown, a transmission assembly 7 is also included, and the transmission assembly 7 includes a pulley 71, a flat belt 72, a winding wheel 73, a backguy 74, a second scroll spring 75 and a first guide block 76, and the left and right sides of the front wall of the garbage collection box 1 Both sides are equipped with belt pulley 71, two belt pulleys 71 are arranged symmetrically left and right, belt pulley 71 is connected with garbage collection box 1 through the mode of bearing seat connection, belt pulley 71 is positioned at gear 83 below, and there is a flat belt between two belt pulleys 71. Belt 72, right side pulley 71 rear side is provided with reel 73, and reel 73 is coaxially connected with right side pulley 71, is wound with backguy 74 on the reel 73, and backguy 74 tail end is connected with cover plate 2, left A second scroll spring 75 is connected between the side pulley 71 and the outer wall of the garbage collection box 1, a...

Embodiment 3

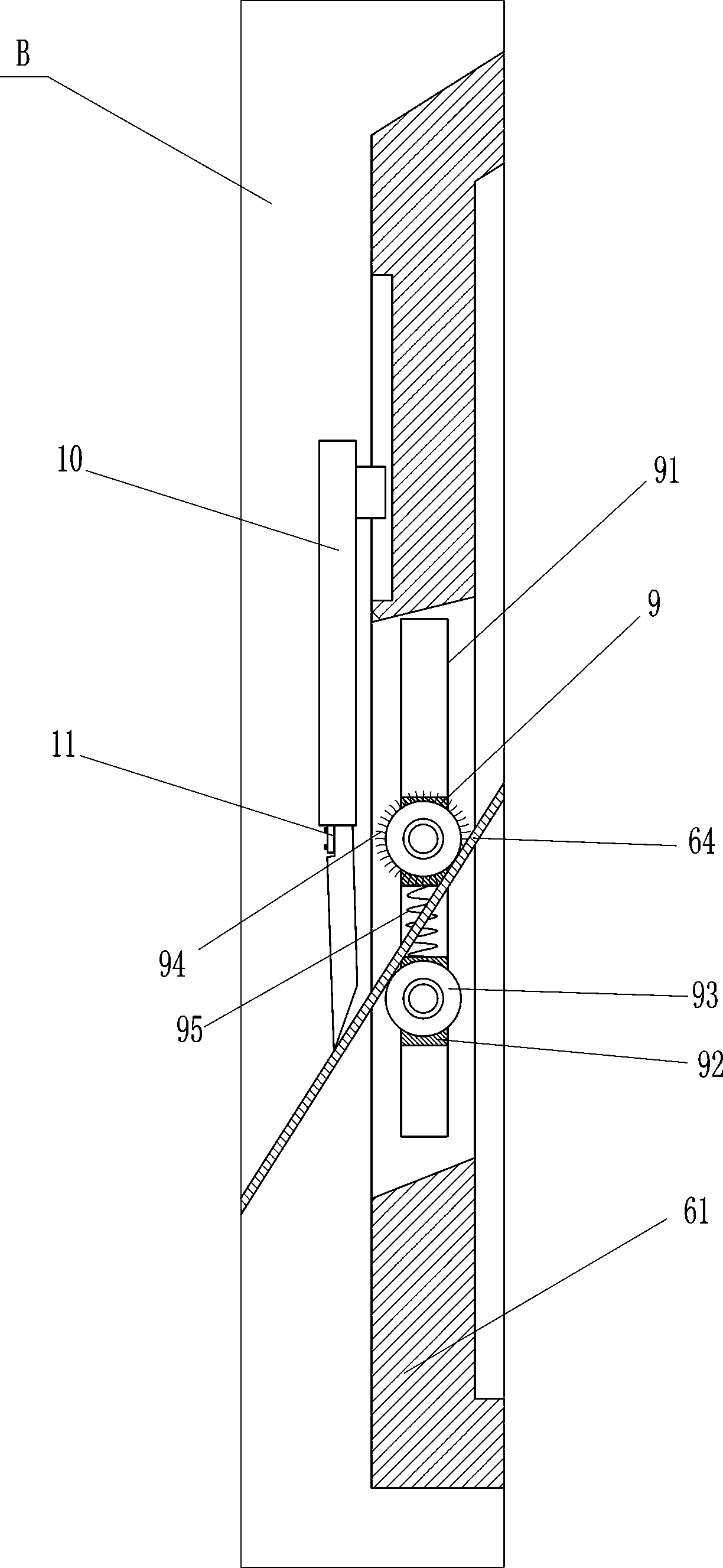

[0034] Such as Figure 5 As shown, it also includes a second guide block 10 and a scraper 11. The left wall outside the installation frame 61 is slidably provided with a second guide block 10. The second guide block 10 can vertically reciprocate on the installation frame 61. The bottom of the guide block 10 and the second guide block 10 is connected with a scraper 11 for scraping out impurities on the guide cloth 64 , and the scraper 11 is in contact with the top surface of the guide cloth 64 .

[0035] When the guide cloth 64 is withdrawn, under the action of the second guide block 10, the scraper 11 can move on the installation frame 61 according to the angle at which the guide cloth 64 is pulled out, so that the scraper 11 and the guide cloth 64 are always in contact In this way, all the rubbish on the surface of the guide cloth 64 can be scraped off, preventing the rubbish from being rolled together with the guide cloth 64, ensuring the cleanliness of the guide cloth 64, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com