Automatic cleaning device for eccentric separators

An automatic cleaning and separator technology, applied in centrifuges and other directions, can solve problems such as hidden safety hazards, difficulty in comprehensive cleaning, manual cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

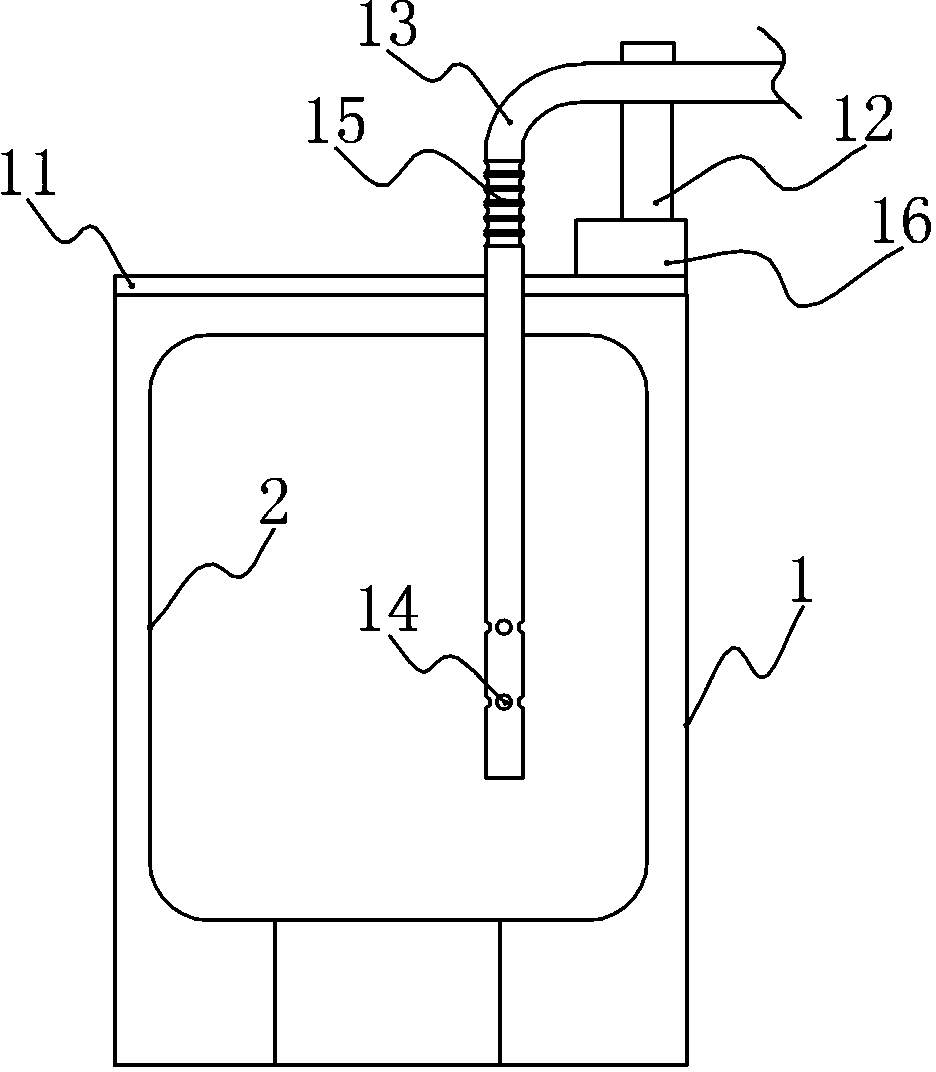

[0010] Such as figure 1 As shown, the automatic cleaning device for the eccentric separator of the present invention includes a drum shell 1, a frequency conversion deceleration motor is fixed inside the drum housing 1, the frequency conversion deceleration motor is eccentrically connected with the cam through a coupling, and the rotating shaft of the drum 2 is connected to the cam Connection; the upper end of the drum shell 1 is open, and the edge of the opening protrudes upwards to form a circle of liquid baffles 11. A bracket 12 is fixedly installed on the side wall of the opening, and a pneumatic ball valve is fixedly installed on the bracket 12. The water pipe 13, the water pipe 13 forms a cantilever, the end of the water pipe 13 is located in the drum 2, and the side wall of the water pipe 13 is provided with eight spray holes 14, and each of the eight spray holes 14 is divided into two groups of four. Groups of spray holes 14 are uniformly distributed on the side wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com