Oxidation fan operation optimization algorithm based on particle swarm optimization

A technology of particle swarm optimization and oxidation fan, which is applied to the separation of dispersed particles, design optimization/simulation, chemical instruments and methods, etc., can solve the problems of slurry quality deterioration, energy consumption increase, and false liquid level of the absorption tower, etc. Economic and environmental benefits, reduction of material consumption and energy consumption, and reduction of environmental risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0035] Example figure 1 Shown:

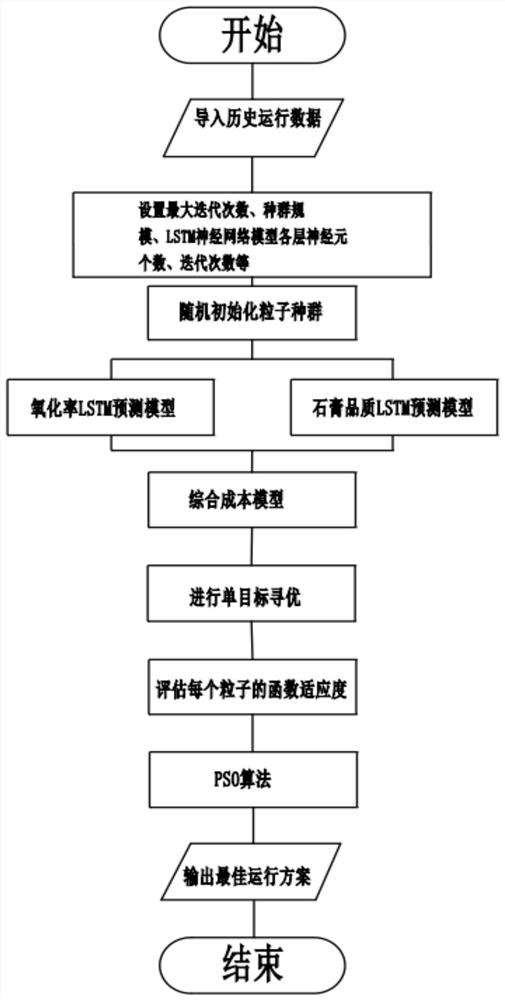

[0036] An oxidation fan operation optimization algorithm based on particle swarm optimization, comprising the following steps:

[0037] S1: Based on the historical operation data, find out the influencing factors that affect the operation efficiency of the oxidation fan, and establish a data set. The influencing factors include sulfite concentration, pH value, flue gas volume, slurry density, slurry volume, flue gas SO2 concentration, oxidation rate and Gypsum quality, specifically: the historical data collection interval is 0.5s, and the fluctuation curve of oxidation rate and gypsum quality is recorded emphatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com