Electrophoresis apparatus and process suitable for automobile leaf spring

An automobile steel plate and electrophoresis technology, applied in the direction of electrophoretic plating, electrolytic paint, coating, etc., can solve the problems of steel plate spring assembly ear hole paint sticking, not meeting the salt spray resistance time, poor paint film adsorption effect, etc., to achieve thermal The effect of improving exchange efficiency, reducing environmental risks, and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

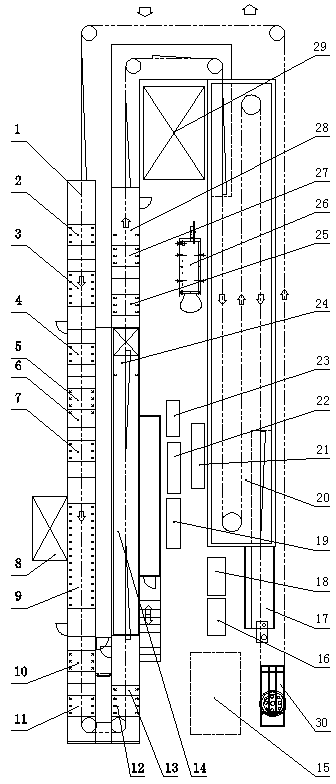

[0027] See figure 1 , an electrophoresis equipment suitable for automobile leaf springs, including a conveying system, a pretreatment system, a cathode electrophoresis system, a drying system and a cooling system arranged in sequence from front to back, and the pretreatment system, cathode electrophoresis system, Electronic control system connected with UF spray equipment, drying system and cooling system with ultrafiltration system 22;

[0028] The conveying system is a circulating conveying chain 1, and the circulating conveying chain is arranged above the pre-treatment system, the cathode electrophoresis system, the UF spraying device, the drying system and the cooling system in sequence;

[0029] Among them, the pre-treatment system includes a pre-degreasing device 2 arranged in sequence from front to back, a degreasing spray device 3 connected with a heating device 26 of a water heater, a water-washing spray chamber 4, and a second water-washing spray chamber 5. Fresh wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com