Layer-by-layer acidification and stratified water injection method

A layer-by-layer water injection and layer-by-layer technology, which is applied to earthwork drilling, wellbore/well valve devices, cleaning tools, etc., can solve the problems of increased material costs, long cycle, and acid liquid cannot be discharged on site, and achieve saving the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

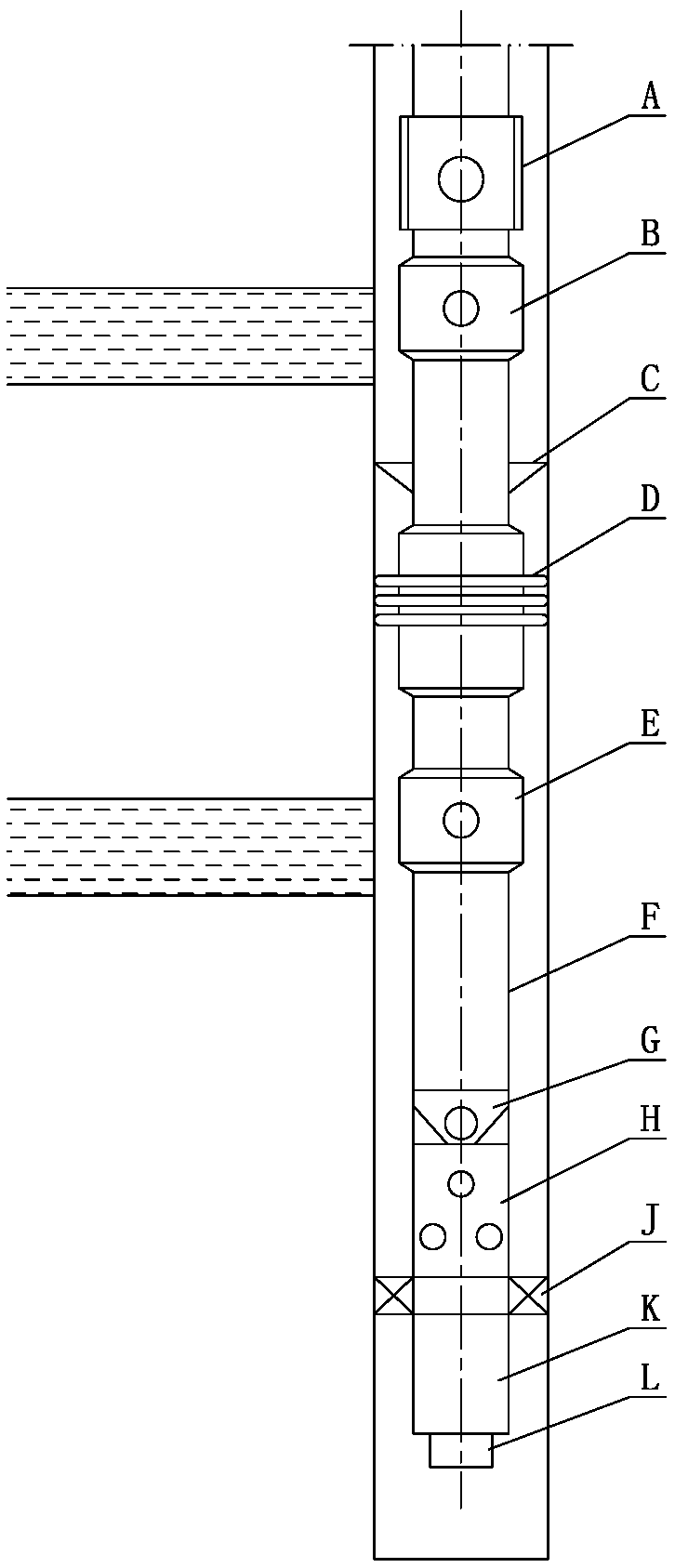

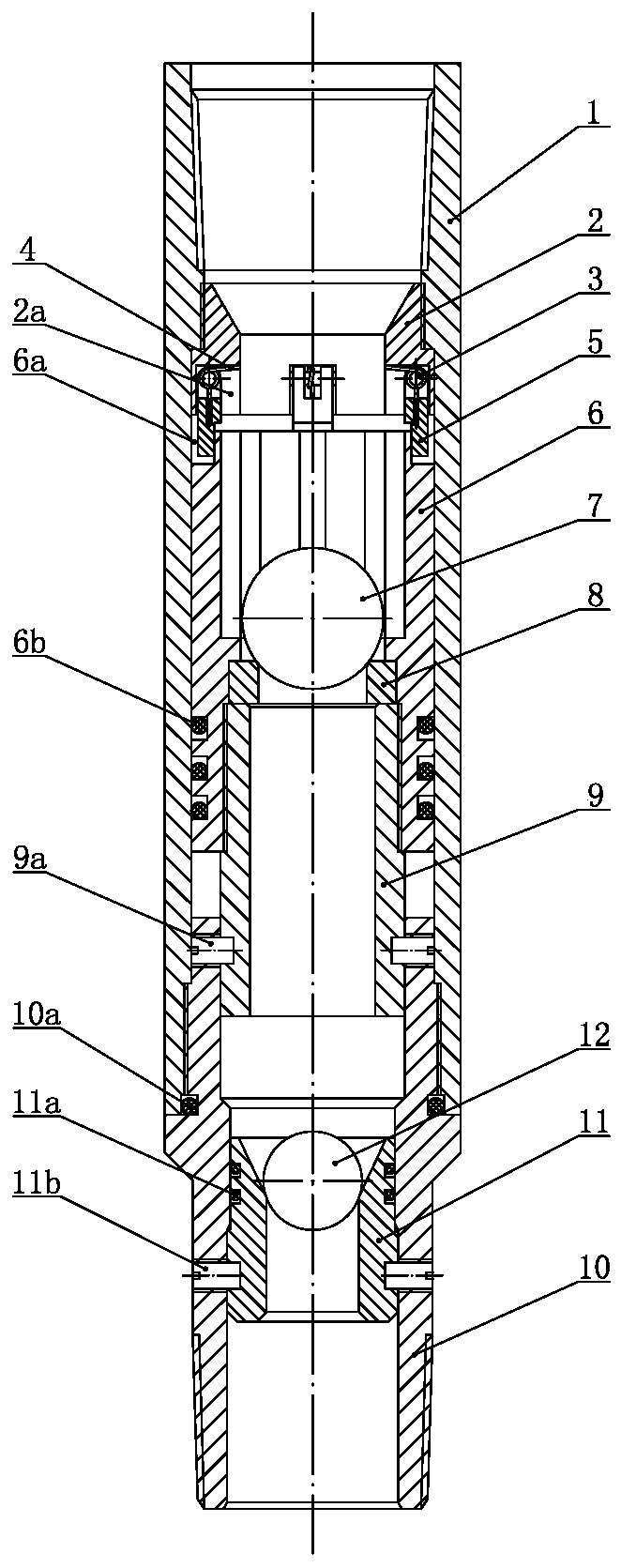

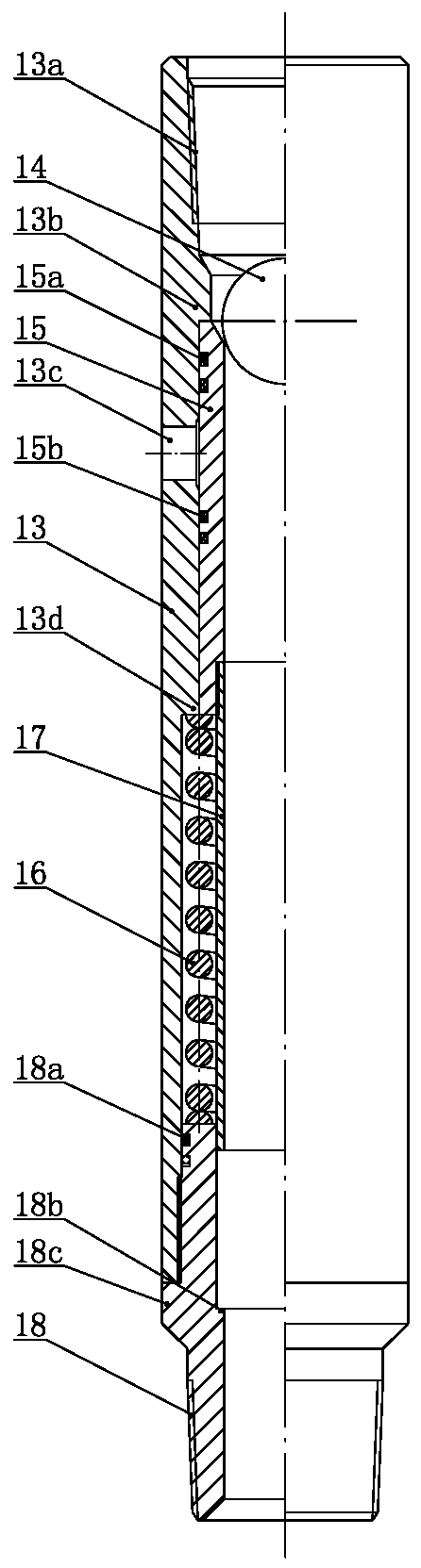

[0026] The method for layer-by-layer acidification and layered water injection of the present invention comprises the following steps in turn: (1) down the acid injection integrated pipe string into the casing, the acid injection integrated pipe string is as follows: figure 1 As shown, from top to bottom, it includes switch valve A, upper eccentric water distributor B, packer D, lower eccentric water distributor E, intermediate oil pipe F, acidizing check valve G, screen pipe H, paint oil pipe K and plug L; a centralizer C can be installed above the packer D to make the expansion of the rubber cartridge more uniform when the packer D is set, and a tubing holder J can be installed between the screen H and the paint tubing K.

[0027] ⑵According to the different clogging conditions of the upper and lower water injection layers, the pretreatment liquid is configured, and the respective acid liquids are configured.

[0028] (3) Start the cement truck for positive circulation, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com