Automatic liquid level glue injection detection device and automatic liquid level glue injection method

An automatic detection device and glue injection technology, which is used in measuring devices, liquid level indicators, lubrication indicating devices, etc., can solve the problems of complex glue injection process control and high cost, and achieve high control accuracy, low cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

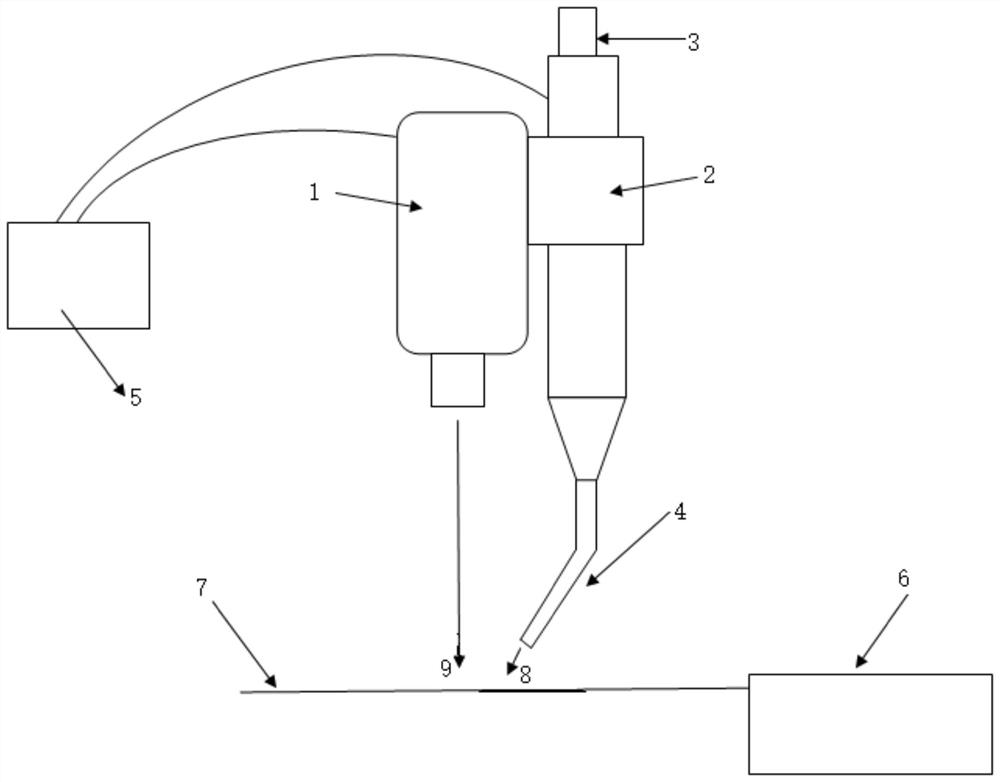

[0040] A liquid level glue injection automatic detection device, such as figure 1 As shown, it includes a control unit 5 and a monitoring unit electrically connected to the control unit 5;

[0041] The detection unit includes a range finder 1, a switching valve 2 and a glue injection pipeline 3. The distance gauge 1 is equipped with a probe, which is located directly above the glue injection point. The switch valve 2 is installed on the glue injection pipeline 3 and is located at the distance measuring On the side of the outer wall of the meter 1, the glue injection pipeline 3 and the rangefinder 1 are all vertically arranged, the inlet end of the glue injection pipeline 1 is connected to the outlet of the external glue injection raw material, and the outlet end of the glue injection pipeline 1 is connected to an oblique glue injection device. The head 4, the outlet end of the oblique glue injection head 4 is located above the glue injection point; the rangefinder 1 and the sw...

Embodiment 2

[0043] Except for the following content, all the other contents are the same as in Example 1.

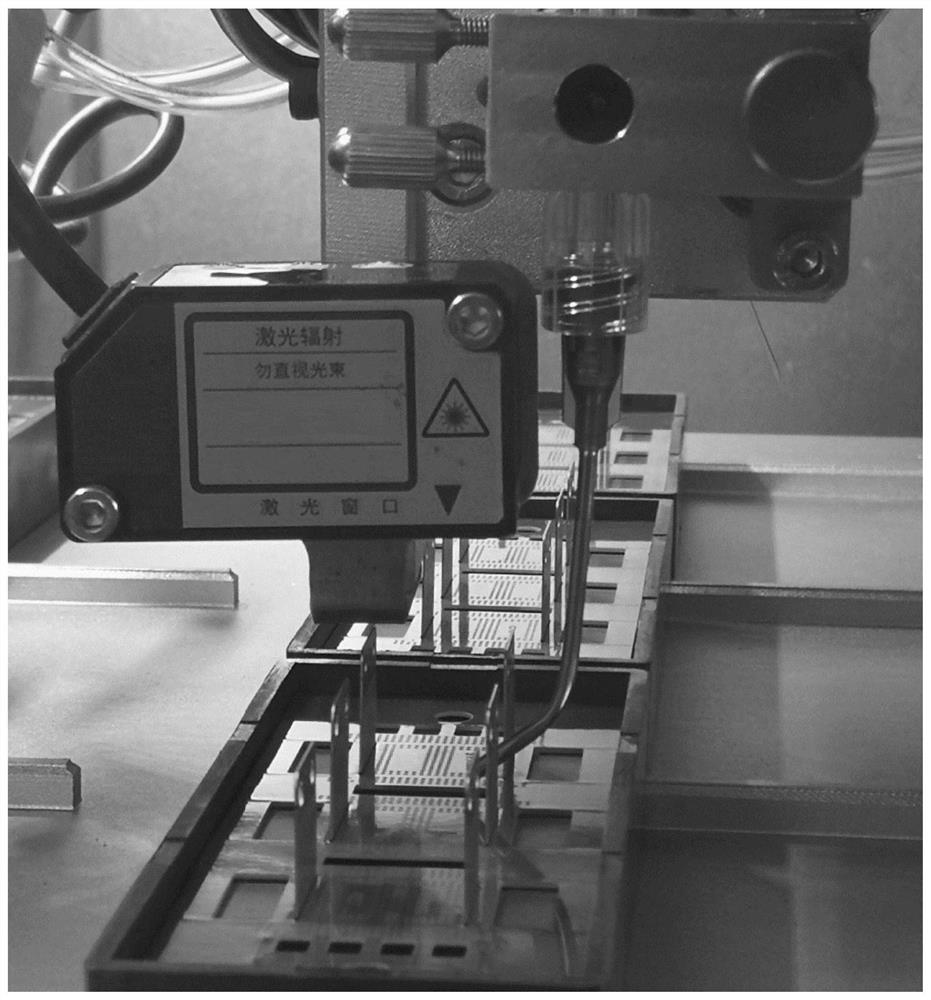

[0044]The control unit 5 includes a controller and a display electrically connected to the controller. The range finder 1 is a laser range finder. The distance between the probe of the rangefinder 1 and the glue injection point is 10 mm to 40 mm; the angle between the horizontal plane where the inclined glue injection head 4 and the glue injection point is located is 45° to 60°; The distance between glue points is 0mm~2mm.

[0045] It should be noted that the specific time needs to be determined by programming according to the specific experiment of the leveling and liquid surface sinking time jointly formed by the viscosity of the glue and the internal shape of the potting structure. The liquid with higher viscosity generally has a slower leveling speed; the internal cavity structure is complex and the gap is narrow, and the sinking speed of the liquid surface will also be slowed...

Embodiment 3

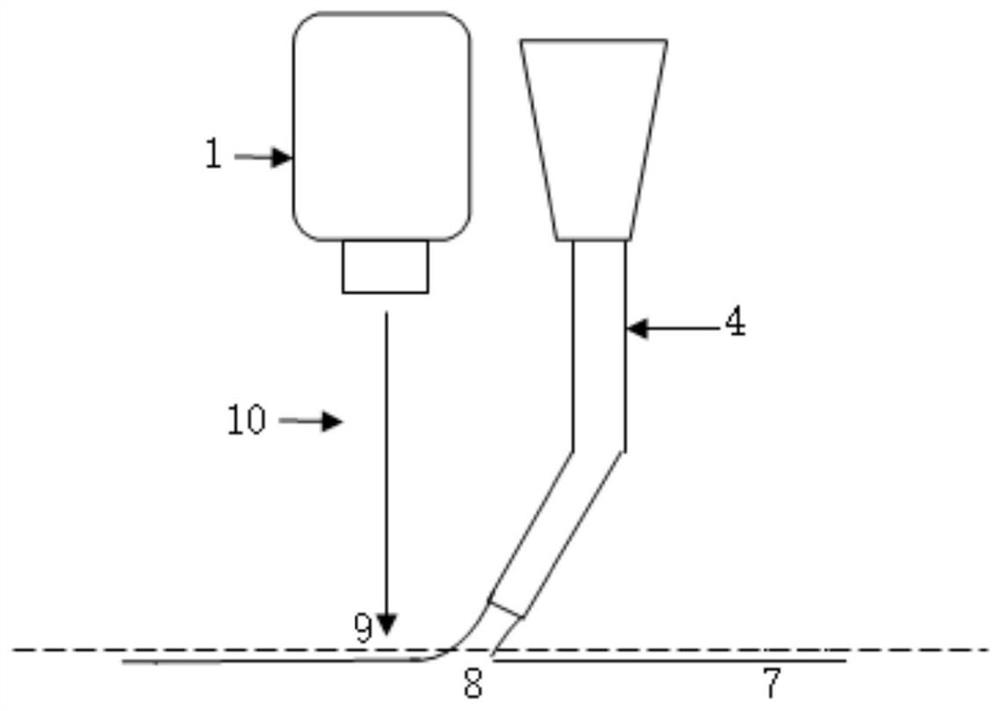

[0047] A glue injection method based on the automatic liquid level control of the liquid level glue injection automatic detection device, such as figure 2 shown, including the following steps:

[0048] Step 1) Install the oblique glue injection head 4, adjust the inclination angle of the oblique glue injection head 4, so that the glue liquid flowing out of the outlet end of the oblique glue injection head 4 is located on the glue injection point, and the glue injection point is located on the rangefinder 1 The light spot detection point of the upper probe;

[0049] Step 2) The control unit 5 controls the switch valve 2 to open, so that the glue is injected through the glue injection pipeline 3 and the inclined glue injection head 4, and the control unit 5 is provided with a preset height;

[0050] Step 3) The rangefinder 2 measures the height of the glue injection, and transmits the measured real-time glue injection height to the control unit 5, and the control unit 5 receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com