Filter pressing device for producing amino acid

An amino acid and indenter technology, applied in the chemical industry, can solve the problems of overflow, affecting product quality, amino acid waste, etc., and achieve the effect of reducing particle diameter, protecting surrounding environment and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

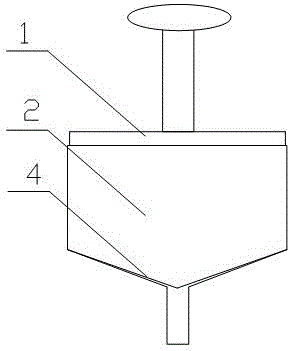

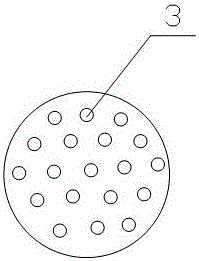

[0013] like figure 1 The shown filter press device for amino acid production includes a press head 1 and a funnel 2, the inner diameter of the funnel 2 matches the outer diameter of the press head 1, the press head 1 can be pressed into the funnel 2, and the press head A group of counterbore 3 is evenly opened on the bottom of 1; the inner wall of the funnel 2 is evenly opened with counterbore, and the diameter of the counterbore is 20cm.

[0014] The curved opening in the funnel 2 is filled with a layer of 200-400µm biofilm, and the diameter of the curved opening in the funnel is 40cm.

[0015] In the actual work of the present invention, due to the counterbore design of the indenter and the funnel, when the indenter is pressurized and moves downward, there will be no phenomenon of amino acid splashing due to excessive air pressure, and it will not be affected by the splash of amino acids. Surroundings. At the same time, it is designed to fill a layer of biofilm between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com