Graphite spray device and spray method thereof

A technology of spraying device and graphite, applied in spraying device, device for coating liquid on the surface, coating and other directions, can solve problems such as inability to spray, waste of graphite milk, environmental pollution, etc., and achieve good spraying effect and protect the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

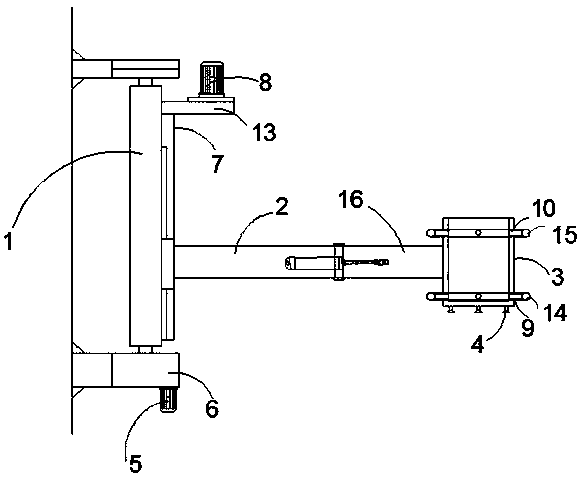

[0027] Embodiment one: if figure 1 As shown, a graphite spraying device and the spraying method of the graphite spraying device include a frame arranged on one side of the forging press, a movable frame 1 which is rotated on the frame, and one end slides along the vertical direction The elevating frame that is arranged on the movable frame 1, the spraying bucket 3 that is used for storing graphite milk that is fixedly arranged on the other end of the lifting frame, the opening of the spraying bucket 3 faces upwards, and the bottom of the spraying bucket 3 Four nozzles 4 communicated with the inner chamber are provided, and a first device for moving the movable frame 1 to / from the forging station of the forging press is arranged between the movable frame 1 and the frame. A driving mechanism, a second driving mechanism for driving the lifting frame to go up and down is arranged between the lifting frame and the movable frame 1 .

[0028] In this embodiment, preferably, the rota...

Embodiment 2

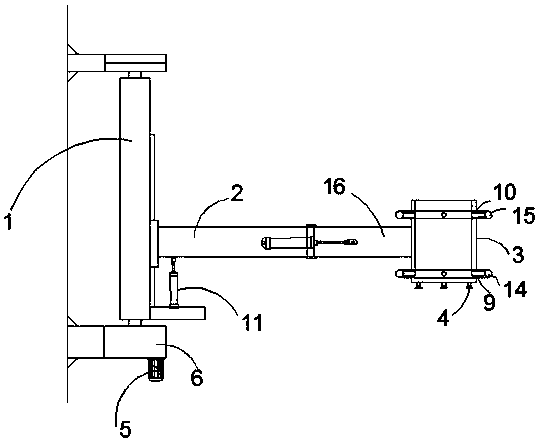

[0035] Embodiment two: if figure 2 As shown, the difference from Embodiment 1 is that the second driving mechanism is the second driving cylinder 11 arranged on the movable frame 1, and the piston rod of the second driving cylinder 11 is connected with the lifting frame , the second drive cylinder 11 can be an air cylinder or a hydraulic cylinder or the like.

Embodiment 3

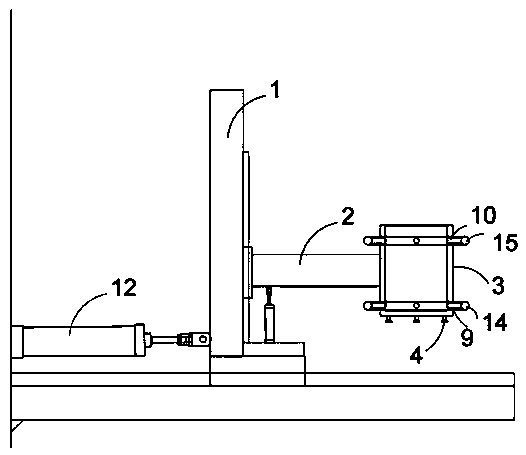

[0036] Embodiment three: as image 3 As shown, the difference from Embodiment 1 is that the movable frame 1 is slidably arranged with the frame along the horizontal direction, and the first driving mechanism is a first driving cylinder 12 arranged on the frame. The piston rod of the first driving cylinder 12 is connected with the movable frame 1, and the first driving cylinder 12 can adopt an air cylinder or a hydraulic cylinder, etc., and the bottom of the movable frame 1 is provided with a second guide, and the frame There is a second guide rail extending along the horizontal direction on the top, and the second guide member is matched with the second guide rail. Of course, the structure of screw movement can also be used to drive the movable frame 1, and it is not limited to the use of cylinders or hydraulic pressure. Compared with Embodiment 1, the way of the cylinder needs enough operating space, that is, the installation and moving space of the movable frame 1 needs a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com