Road finishing machine and method for laying mixed material with a road finishing machine

A technology for refinishing machines and pavements, applied in road repair, roads, roads, etc., can solve the problems of operators not running the ventilation system, noise pollution, ventilation system not being turned on, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

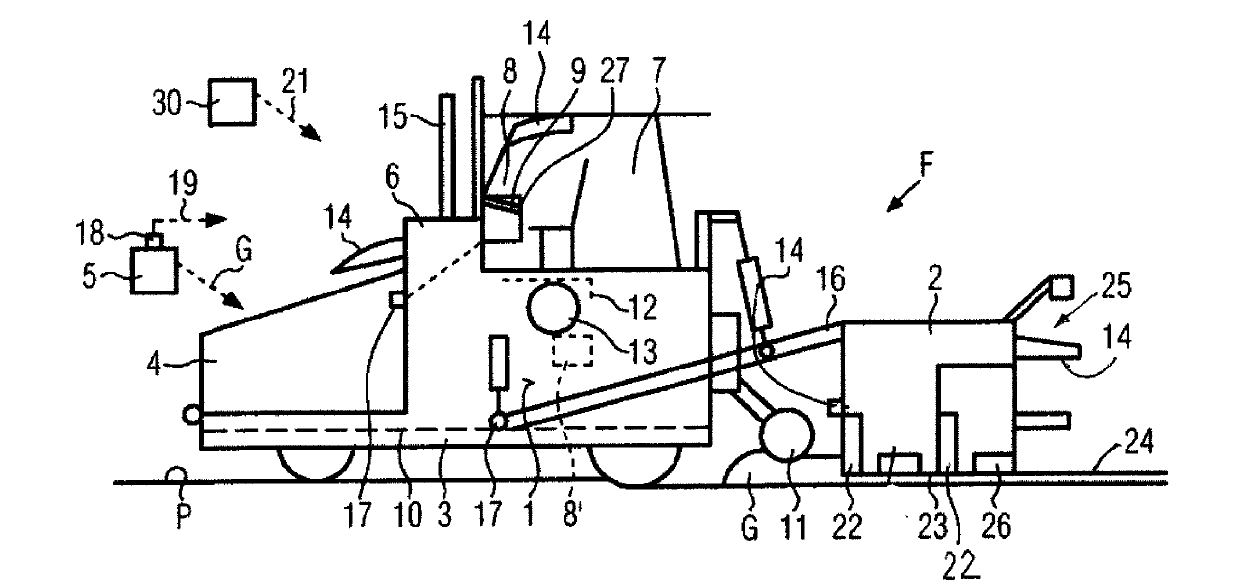

[0025] exist figure 1 The road finishing machine F shown schematically in FIG. 2 comprises a self-propelled tractor 1 operating at a low drive speed during laying and at a faster drive speed during transport and site change drives. At least one screed 2 is towed by the tractor 1 for laying a road surface 24 of material mixture G during the laying drive of the road finishing machine F. The road finisher F has a hopper 4 at the front of the chassis 3 which can be filled with a material mixture G eg from a dump truck, a conveyor belt or a charging truck 5 . A longitudinal conveyor 10 extends to the rear end of the chassis 3 at the bottom side. Behind the hopper 4, a main drive source 6 (such as a diesel engine) is arranged, and behind the main drive source, a driver's platform 7 equipped with a machine console 8 on the chassis 3 is arranged. The machine console 8 comprises, inter alia, a decision section 9, and preferably an input and display section 27, and is connected, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com