Full-closed metallurgy rotary kiln

A rotary kiln, fully enclosed technology, applied in the field of rotary kiln, can solve the problems of workshop and surrounding environment pollution, poor air isolation effect, etc., to achieve the effect of protecting material characteristics, preventing leakage, and preventing entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be described in detail below with reference to the accompanying drawings.

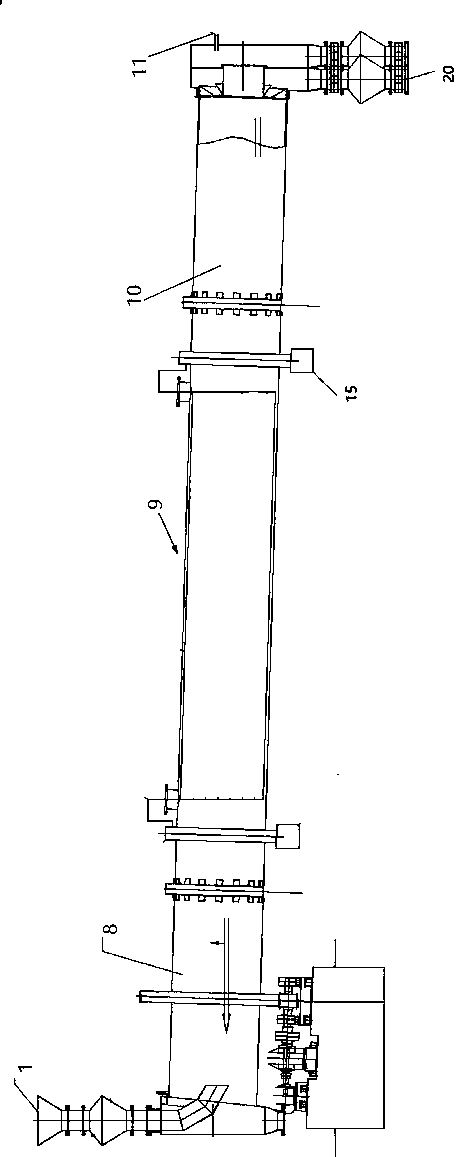

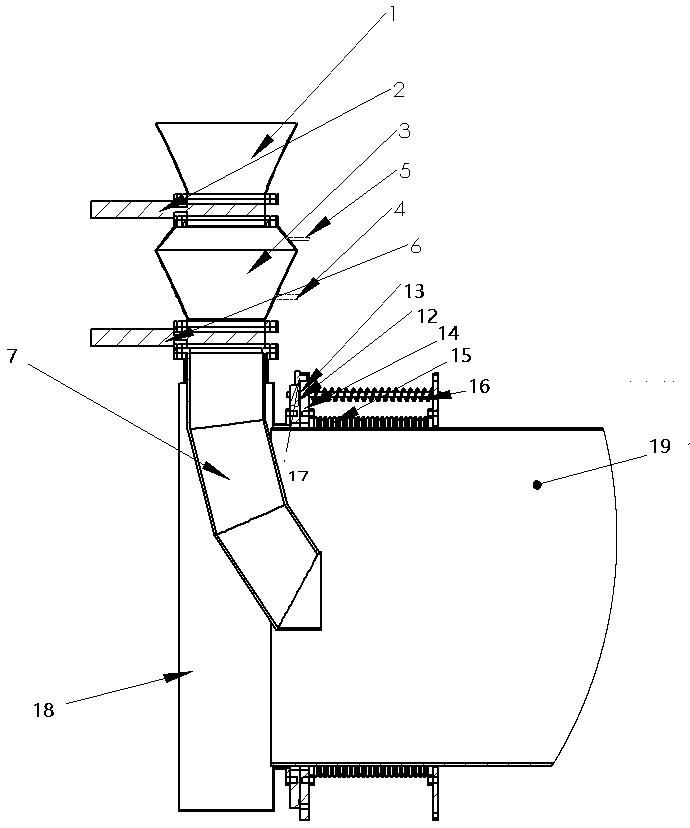

[0019] The technical solution adopted by the present invention to solve the technical problem is: a fully enclosed metallurgical rotary kiln, figure 1 It is a schematic diagram of the overall structure of the rotary kiln. figure 2 It is a structural schematic diagram of the rotary kiln cleaning sealed chamber 3 and the rotating joint.

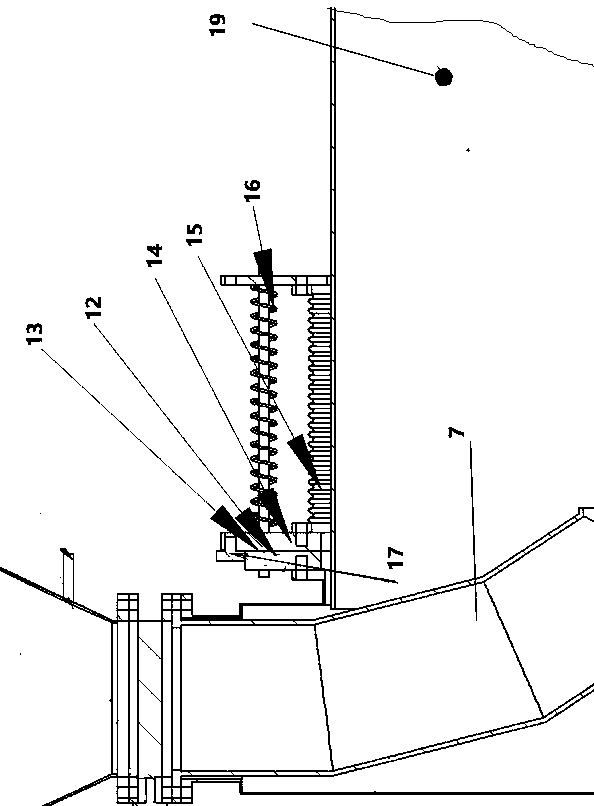

[0020] image 3 Schematic diagram of the enlarged structure of the rotating joint. In the figure, 1 is the feeding bin. The fully enclosed metallurgical rotary kiln includes the kiln head, the kiln barrel 19 and the kiln tail of the rotary kiln. On the side of the kiln head, there is a cleaning and sealing chamber 3 under the feeding chamber, and a feeding pipe 7 is arranged under the cleaning and sealing chamber 3. The feeding pipe 7 is connected to the upper end of the kiln head box 18. 19 extends into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com