Oil and gas field drilling fluid waste treatment-while-drilling system

A drilling mud and treatment system technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of increasing the total amount of waste and treatment costs, groundwater pollution, etc., to achieve Convenient scheduling, environmental protection, simple processing system effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

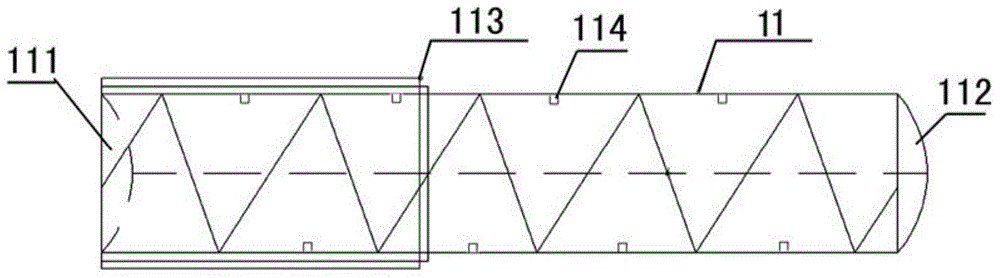

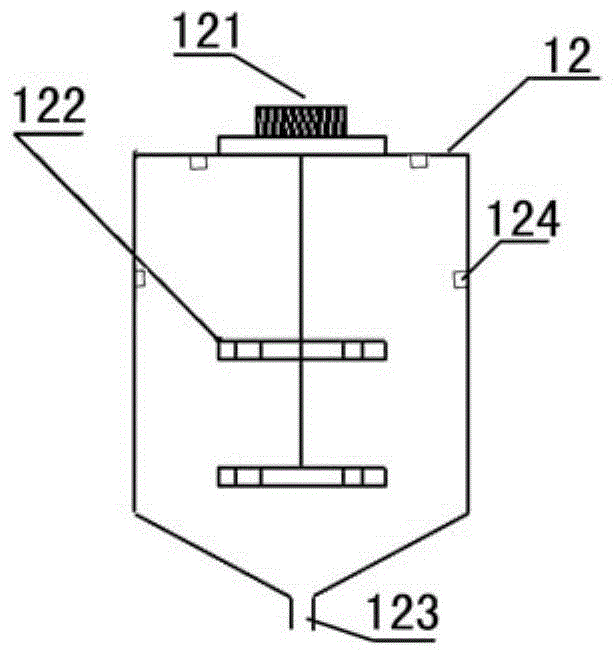

[0028] The processing system of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] The mud waste in the present invention is a mixture of various substances such as drilling sewage, drilling mud and cuttings.

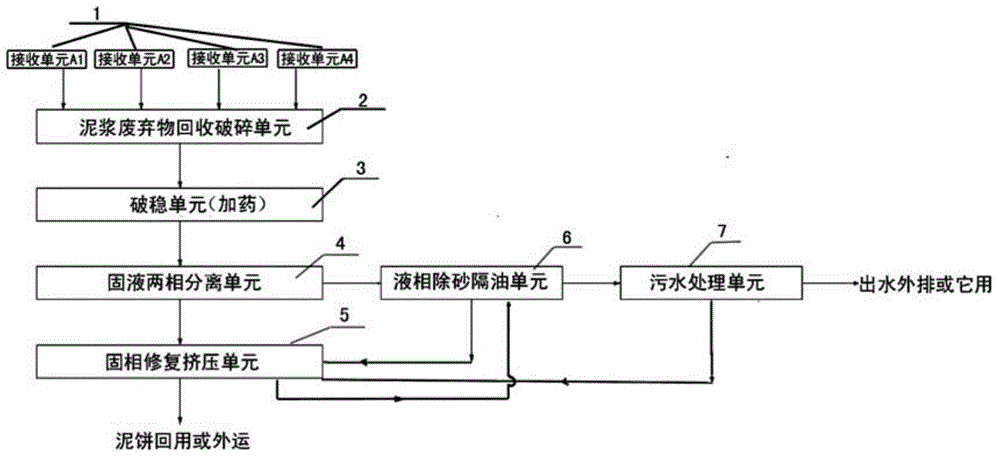

[0030] see figure 1 , an oil and gas field drilling mud waste treatment system while drilling, the treatment system includes a mud waste receiving unit 1, a mud waste recycling and crushing unit 2, a stabilization unit 3, a solid-liquid two-phase separation unit 4, and a solid phase repair extrusion Unit 5, liquid phase desanding and oil separation unit 6, sewage treatment unit 7. Each unit and its connection relationship will be described in detail below.

[0031] The mud waste receiving unit 1 , the inlet is connected with the mud waste discharge outlet of the drilling mud circulation system, and is used to receive the mud waste from the drilling mud circulation system.

[0032] The drilling mud circulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com