Making method of hemp root bast filter paper for anti-fog and anti-haze mask

A technology for preventing haze and filtering paper, which is applied in pulp beating methods, pulping with inorganic alkalis, pulping with organic compounds, etc., can solve the problems of roughness, low application value, difficult processing, etc. The market application prospect is broad and the effect of good filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

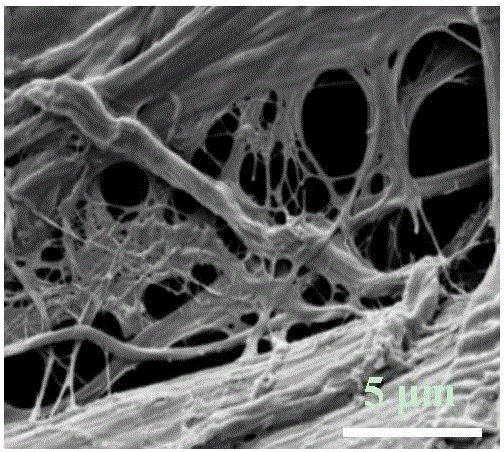

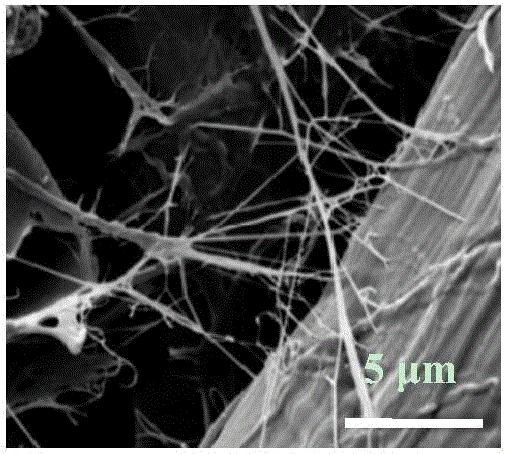

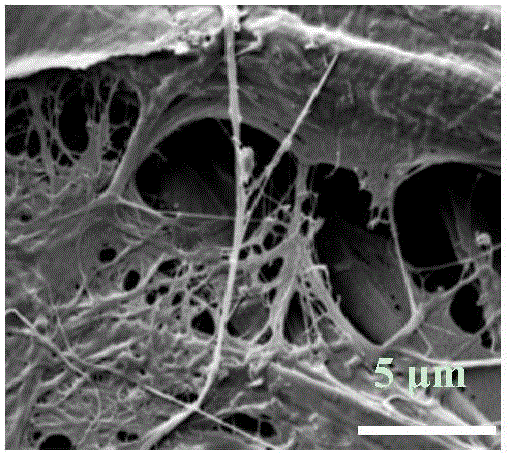

Image

Examples

Embodiment 1

[0028] 1) The bast of the hemp root was provided by Hanma Industry Investment Holding Co., Ltd. (Menghai County, Xishuangbanna Dai Autonomous Prefecture, Yunnan Province). The bast of the hemp root was cut into a length of 5 cm, and the concentration was 14% NaOH and 15% NaOH Anthraquinone is cooked in a 1:1 mixed solution by volume, cooking conditions: temperature 170°C, pressure 0.8 MPa, time 2.5h;

[0029] 2) Perform three bleaching processes: the first process uses 3% NaOH and 0.5% MgSO 4 Prepare a bleaching agent at a volume ratio of 1:1, place the cooked hemp root bast in the bleaching agent to form a slurry, the concentration of the slurry is 15%, the bleaching temperature is 110°C, the time is 1h, and the pressure is 0.7MPa; The second process uses a concentration of 2.5% ClO 2 The aqueous solution is used as the bleaching agent, the bleaching temperature is 70°C, and the time is 2.5h; the third process uses a 3% NaOH solution as the bleaching agent, and the bleaching t...

Embodiment 2

[0035] 1) The bast of the hemp root was provided by Hanma Industry Investment Holding Co., Ltd. (Menghai County, Xishuangbanna Dai Autonomous Prefecture, Yunnan Province). The bast of the hemp root was cut into a length of 5 cm, and the concentration was 14% NaOH and 15% NaOH Anthraquinone is cooked according to the mixed liquid with a volume ratio of 1:3, and the cooking conditions are: temperature 150°C, pressure 1 MPa, time 1.5h;

[0036] 2) Perform three bleaching processes: the first process uses 3% NaOH and 0.5% MgSO 4 Prepare a bleaching agent at a volume ratio of 1:2, place the cooked hemp root bast in the bleaching agent to form a slurry, the concentration of the slurry is 15%, the bleaching temperature is 100°C, the time is 1.5h, and the pressure is 0.7MPa ; The second process uses a concentration of 2.5% ClO 2 The aqueous solution is used as the bleaching agent, the bleaching temperature is 80°C, and the time is 1.5h; the third process uses a 3% NaOH solution as th...

Embodiment 3

[0042] 1) The bast of hemp root was provided by Hanma Industry Investment Holding Co., Ltd. (Menghai County, Dai Autonomous Prefecture, Xishuangbanna, Yunnan Province). Anthraquinone is cooked in a mixed solution with a volume ratio of 1:5. The cooking conditions are: temperature 190°C, pressure 0.6MPa, time 2h;

[0043] 2) Perform three bleaching processes: the first process uses 3% NaOH and 0.5% MgSO 4 Prepare a bleaching agent at a volume ratio of 1:5, place the cooked hemp root bast in the bleaching agent to form a slurry, the concentration of the slurry is 20%, the bleaching temperature is 90°C, the time is 3h, and the pressure is 1MPa; The second process uses a concentration of 2.5% ClO 2 The aqueous solution is used as the bleaching agent, the bleaching temperature is 50°C, and the time is 4h; the third process uses a 3% NaOH solution as the bleaching agent, and the bleaching temperature is 40°C, and the time is 4h;

[0044] 3) Use a ZQS2-45 beater to thaw the slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com