System and method for regenerating a diesel particulate filter

a technology of particulate filter and system, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of ineffective doc-dpf assembly, reduced engine efficiency, and inability to increase engine speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] With reference to the accompanying drawings, the present invention will be described in order for those skilled in the art to be able to implement the invention. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit or scope of the present invention.

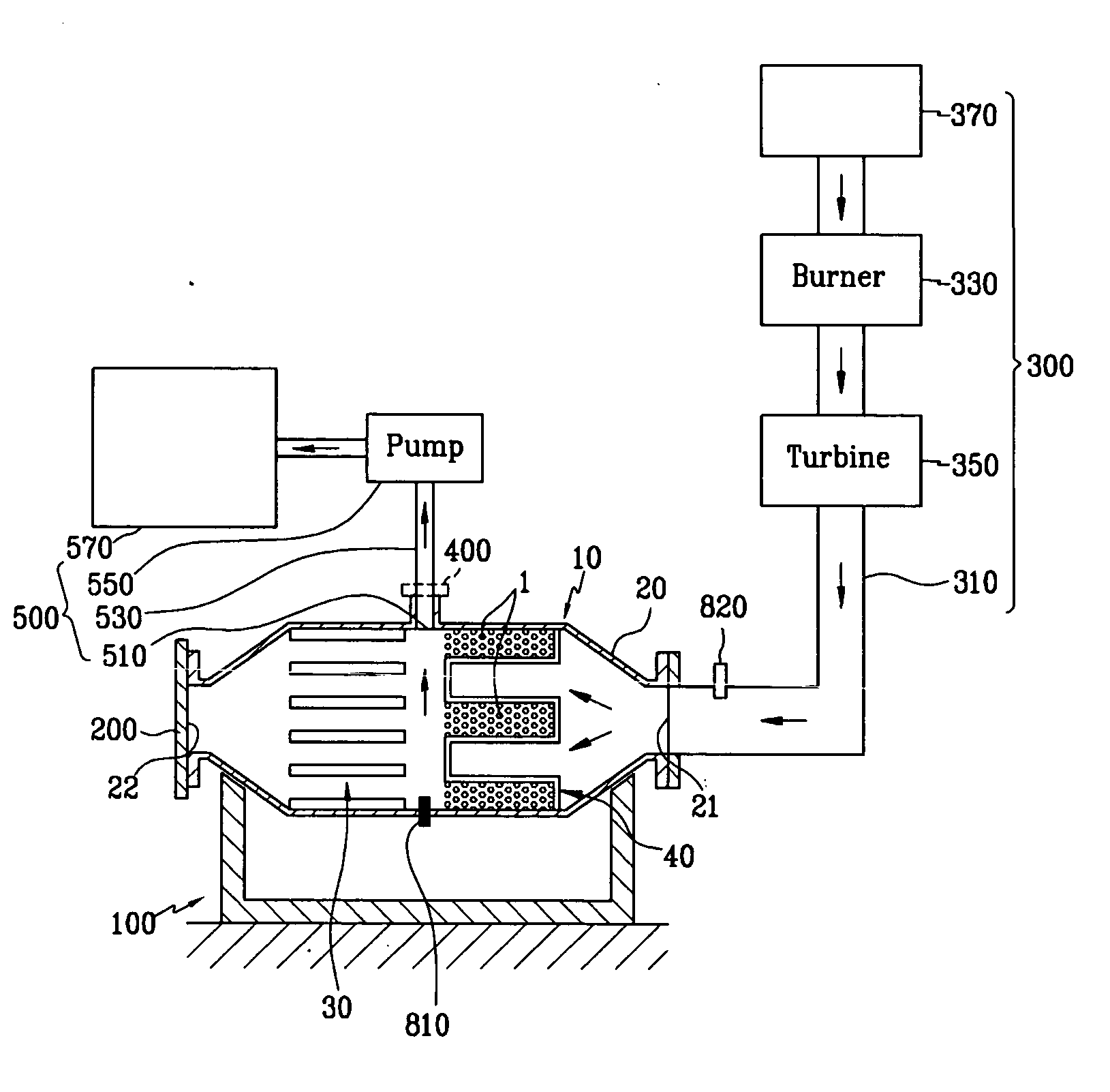

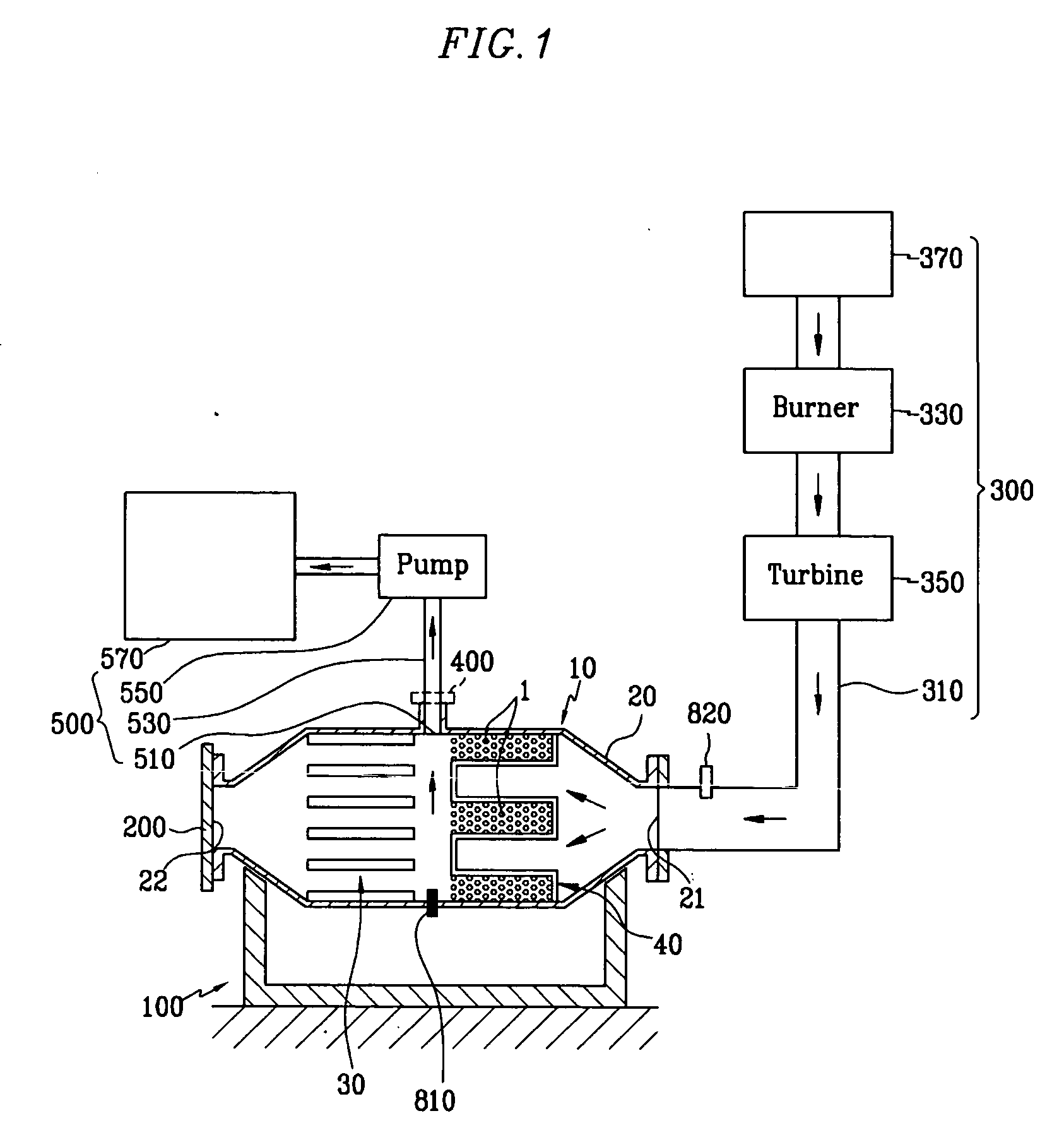

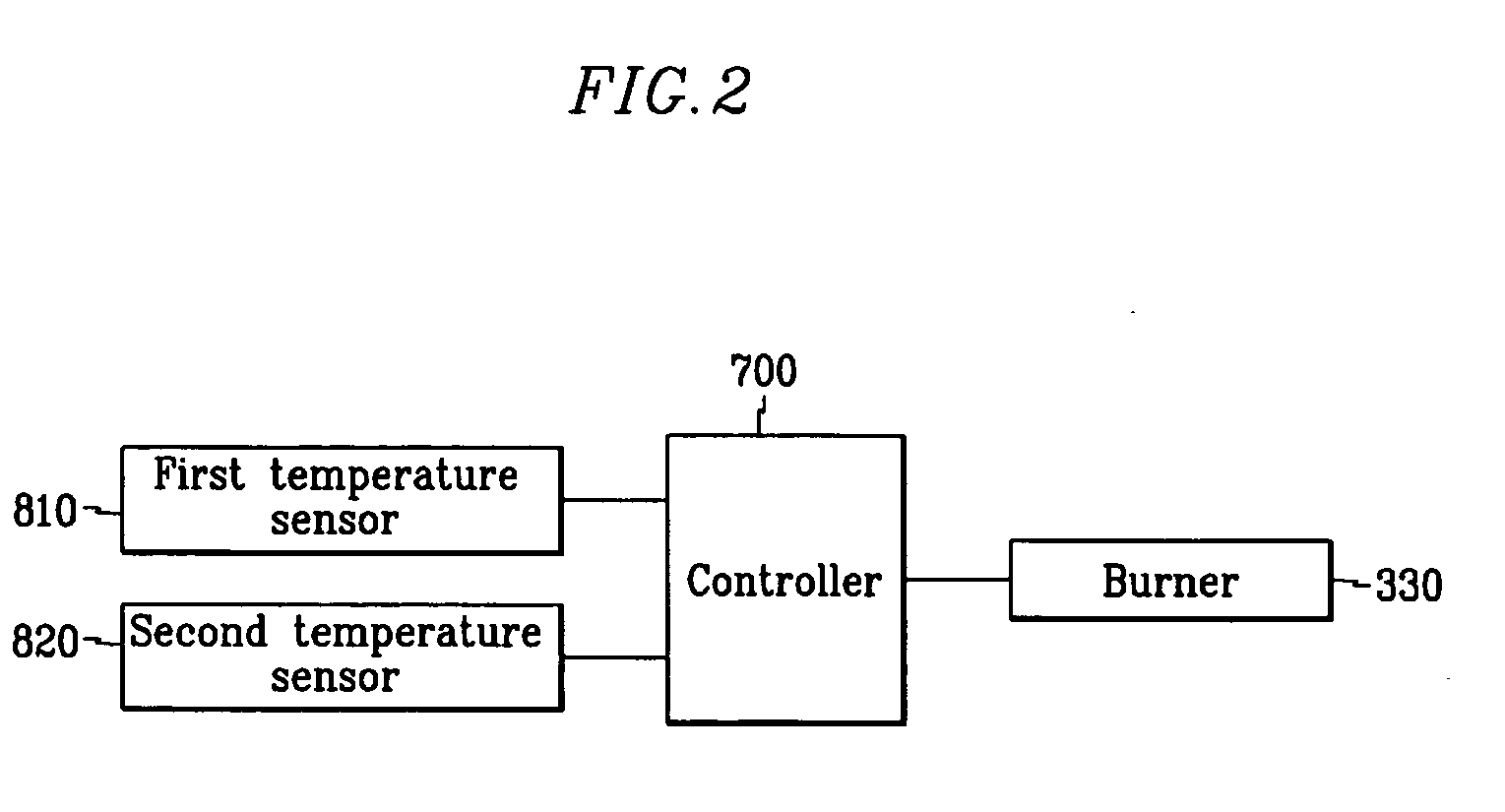

[0026]FIG. 1 is a schematic view showing a system for regenerating a diesel particulate filter according to an exemplary embodiment of the present invention. FIG. 2 is block diagram showing a controller and elements connected to the controller, in a system for regenerating a diesel particulate filter according to an exemplary embodiment of the present invention.

[0027] A system for regenerating a diesel particulate filter according to an exemplary embodiment of the present invention, as shown in FIGS. 1 and 2, includes a fixing part 100, a fluid supplying part 300, a fluid intake part 500, and a controller 700.

[0028] The fixing part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com