Robot with cleaning function

A robot and functional technology, applied in the field of robots, can solve the problems of high labor intensity of cleaning personnel and high risk of high-altitude operations, and achieve the effect of reducing cleaning costs, reducing labor intensity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

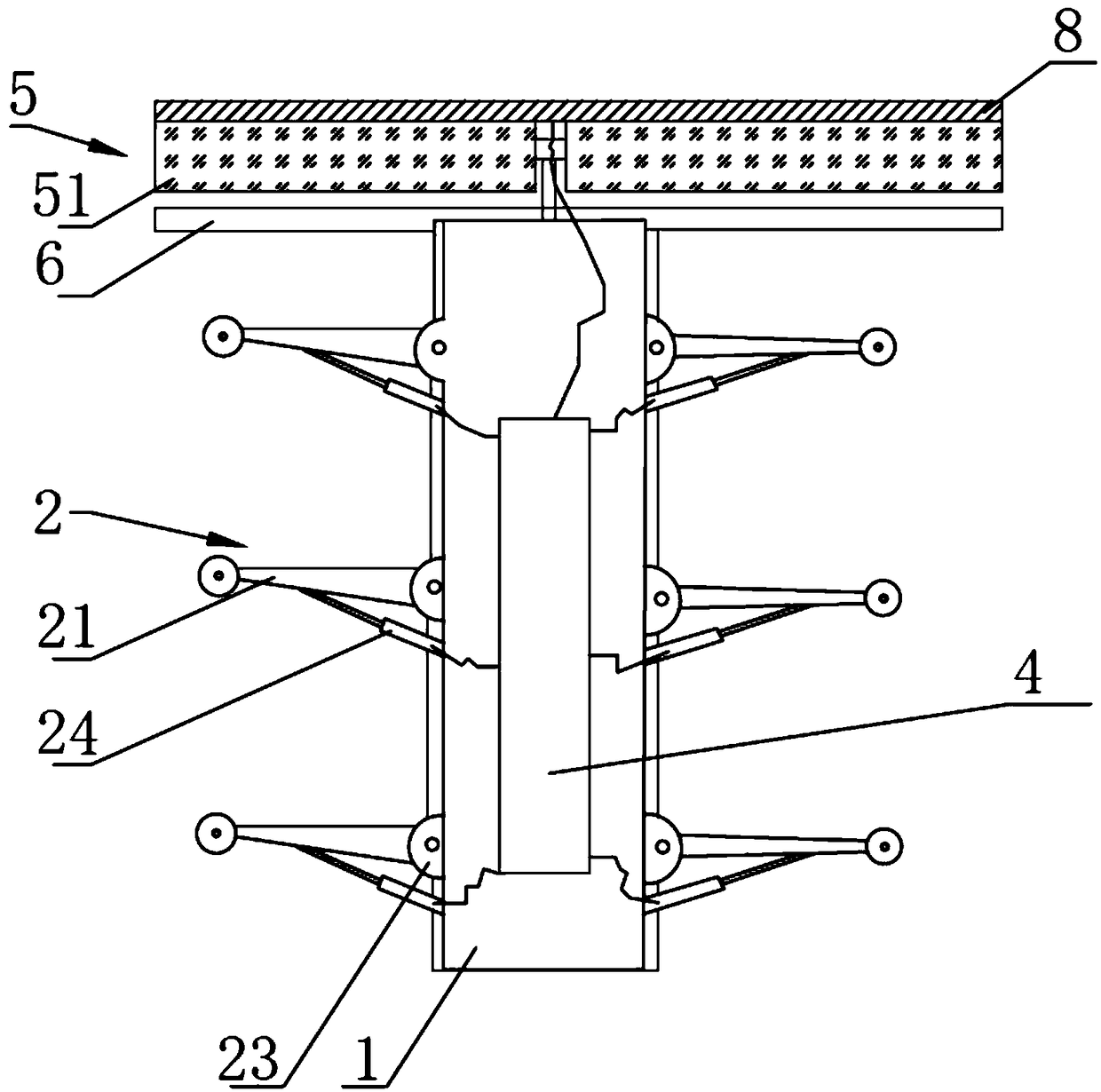

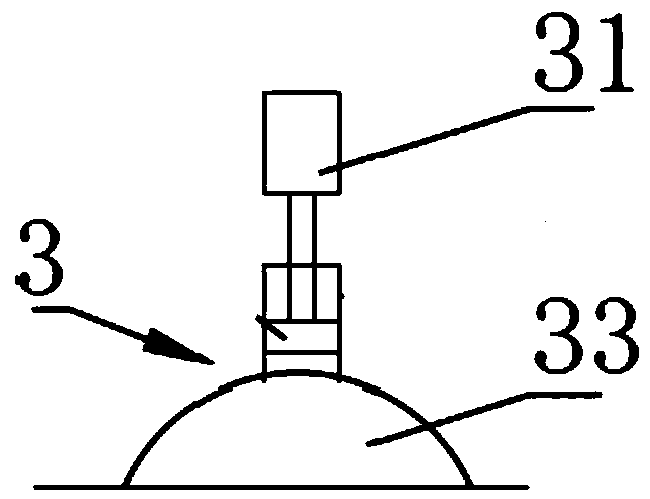

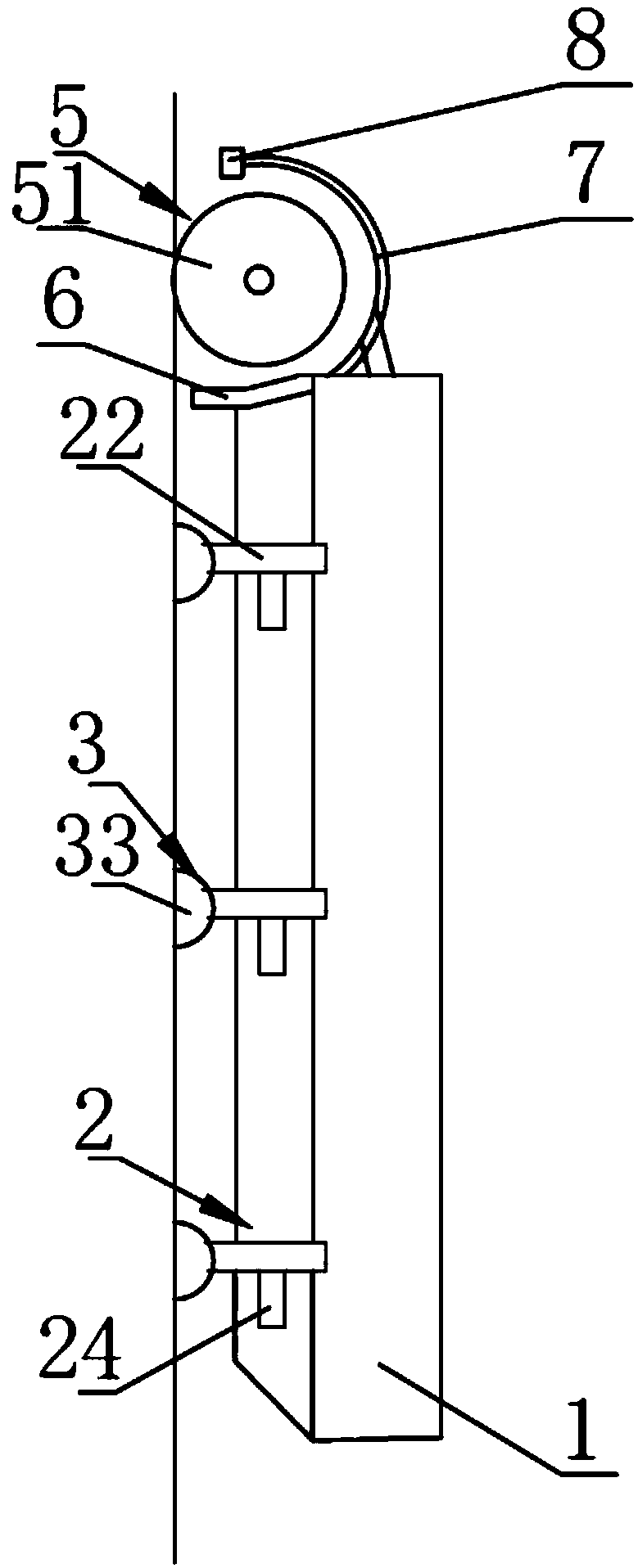

[0035]The present invention provides a robot with a cleaning function, which includes: a frame 1, a plurality of pairs of mechanical legs 2, a plurality of fastening devices 3, a controller 4 and a cleaning device 5, and the plurality of pairs of mechanical legs 2 are respectively related to the The frame 1 is arranged symmetrically, and one end of a plurality of pairs of mechanical legs 2 is symmetrically arranged on both sides of the frame 1 with respect to the frame 1, and the cleaning device 5 is arranged at one end of the frame 1 A plurality of fastening devices 3 are arranged on the other ends of the plurality of mechanical legs 2 respectively, the fastening devices 3 are fastened to the surface of the object to be cleaned, and the controller 4 is arranged on the frame 1 Above, the controller 4 is connected with the cleaning device 5 and controls the opening and closing of the cleaning device, and the controller 4 is connected with the mechanical leg 2 and controls the mo...

Embodiment 2

[0040] On the basis of Embodiment 1, the mechanical leg 2 of this embodiment includes: a first connecting rod 21, a second connecting rod 22, a third connecting rod 23, a first pushing device 24 and a second pushing device 25, so One end of the third connecting rod 23 is rotatably arranged on the side wall of the frame 1, and the base of the first pushing device 24 is arranged on the upper rear side of one end of the third connecting rod 23. One end of a connecting rod 21 is rotatably connected with the third connecting rod 23, and the base of the first pushing device 24 is rotatably arranged on the side wall of the frame 1, and the base of the first pushing device 24 The output end is rotatably connected to the middle part of the first connecting rod 21, the other end of the first connecting rod 21 is rotatably connected to one end of the second connecting rod 22, and the base of the second pushing device 25 can be Rotately arranged on the first connecting rod 221, the output...

Embodiment 3

[0043] On the basis of Embodiment 2, the first pushing device 24 and the second pushing device 25 of this embodiment are oil cylinders, air cylinders or air compression pumps of the same type.

[0044] Wherein, the model of the electric oil cylinder can be: mob.

[0045] Both the first pushing device and the second pushing device are electric oil cylinders, so that the first pushing device and the second pushing device can be uniformly controlled by the controller, so as to realize different motion states.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com