Method for installing integrated photovoltaic support of solar panel

An installation method and technology of photovoltaic support, applied in the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of destroying natural landforms and surrounding environments, difficulty in adapting to project progress, complex support structures, etc., and achieve protection of natural landforms and the surrounding environment, meet the green environmental protection policy, and simplify the complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific construction steps of the method of the present invention are:

[0010] 1. Remove weeds and floating soil at the installation site of the installation site,

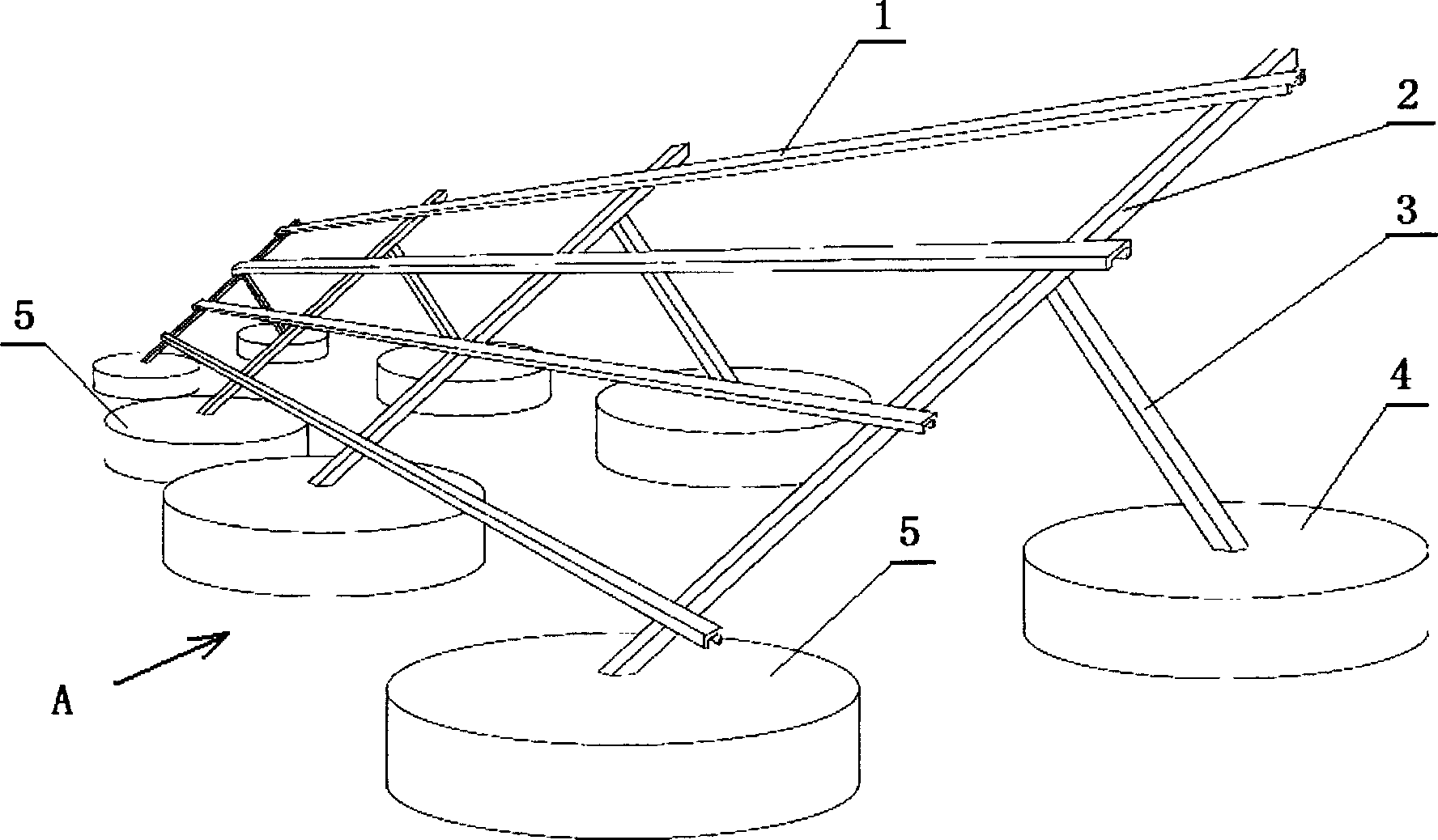

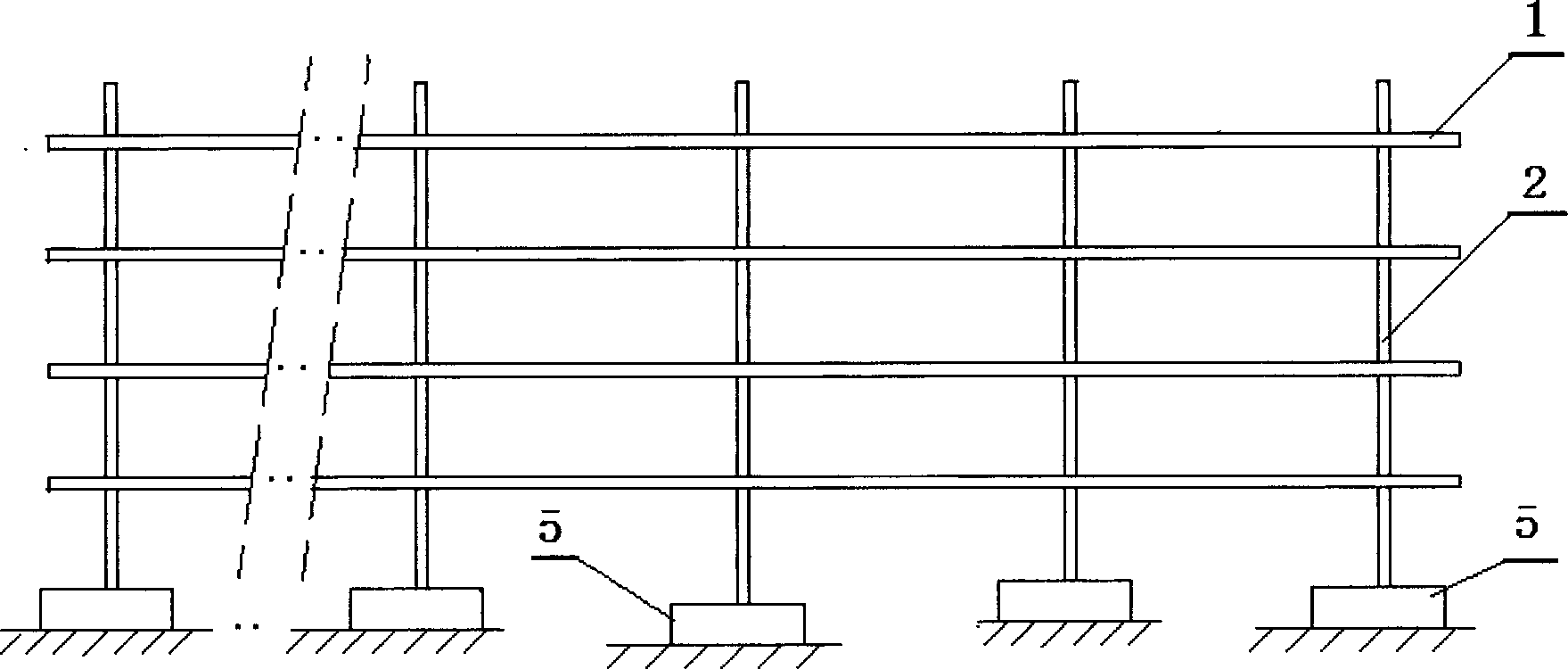

[0011] 2. See figure 1 and figure 2 , Connect the longitudinal beam 2, the cross beam 1 and the support diagonal beam 3 in the existing way, and determine the length of the longitudinal beam 2 and the support diagonal beam 3 according to the installation position,

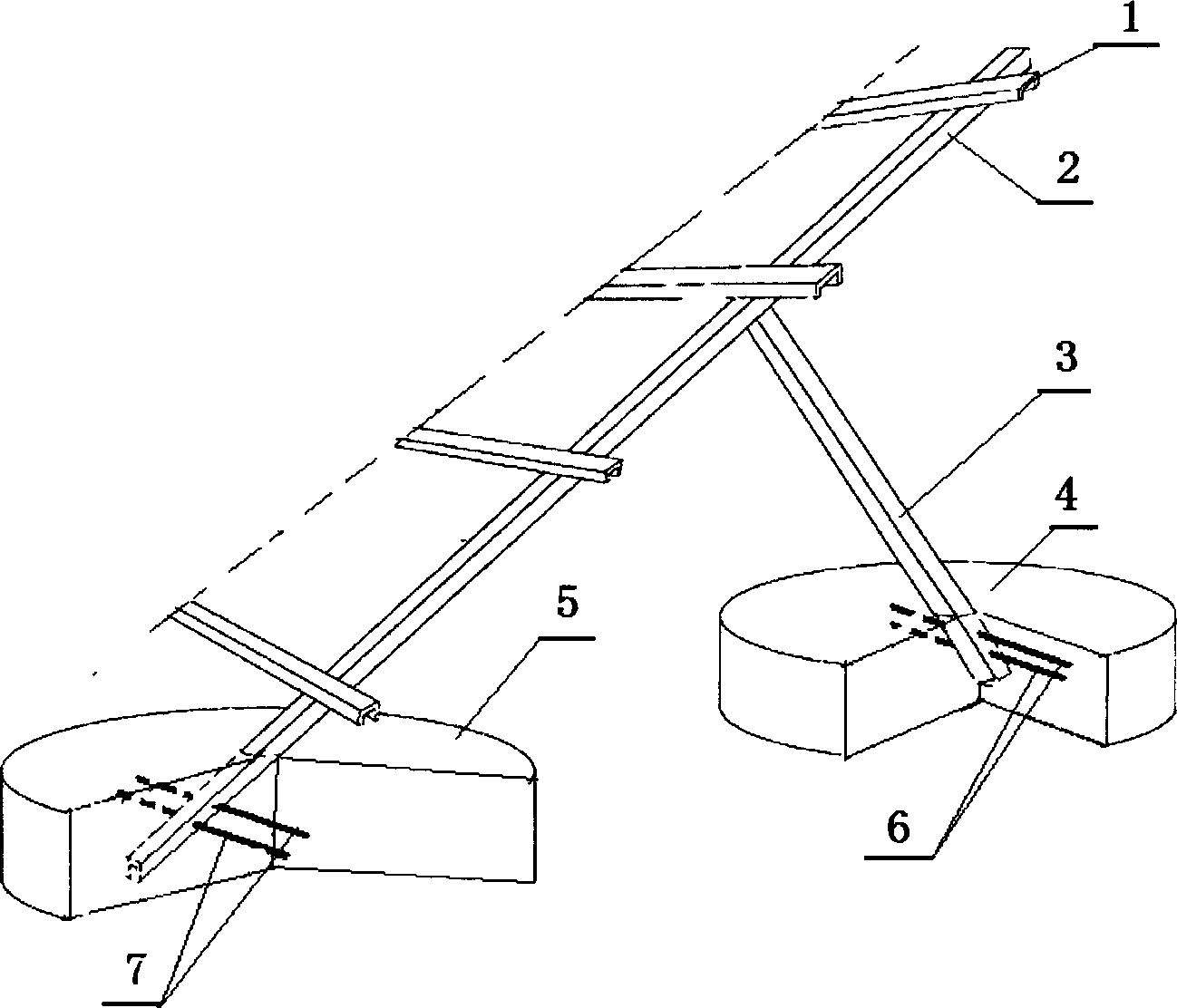

[0012] 3. Install transverse reinforcement 7 at the installation root of the longitudinal beam 2. The reinforcement 7 can be installed by inserting the reinforcement in the opening of the longitudinal beam, or it can be welded and arranged side by side (see image 3 ) Or staggered setting,

[0013] 4. Install transverse steel bars 6 at the installation root of the supporting inclined beam 3. The steel bars 6 can be installed by inserting steel bars in the holes of the longitudinal beams, or they can be welded and arranged side by side (see image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com