Novel process flow and apparatus for decomposing phenate

A technology of process flow and phenoxide, which is applied in the field of new process flow and equipment of phenoxide decomposition, can solve the problems of phenoxide environmental pollution, etc., and achieve the effects of low operating cost, reduced stirring system, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

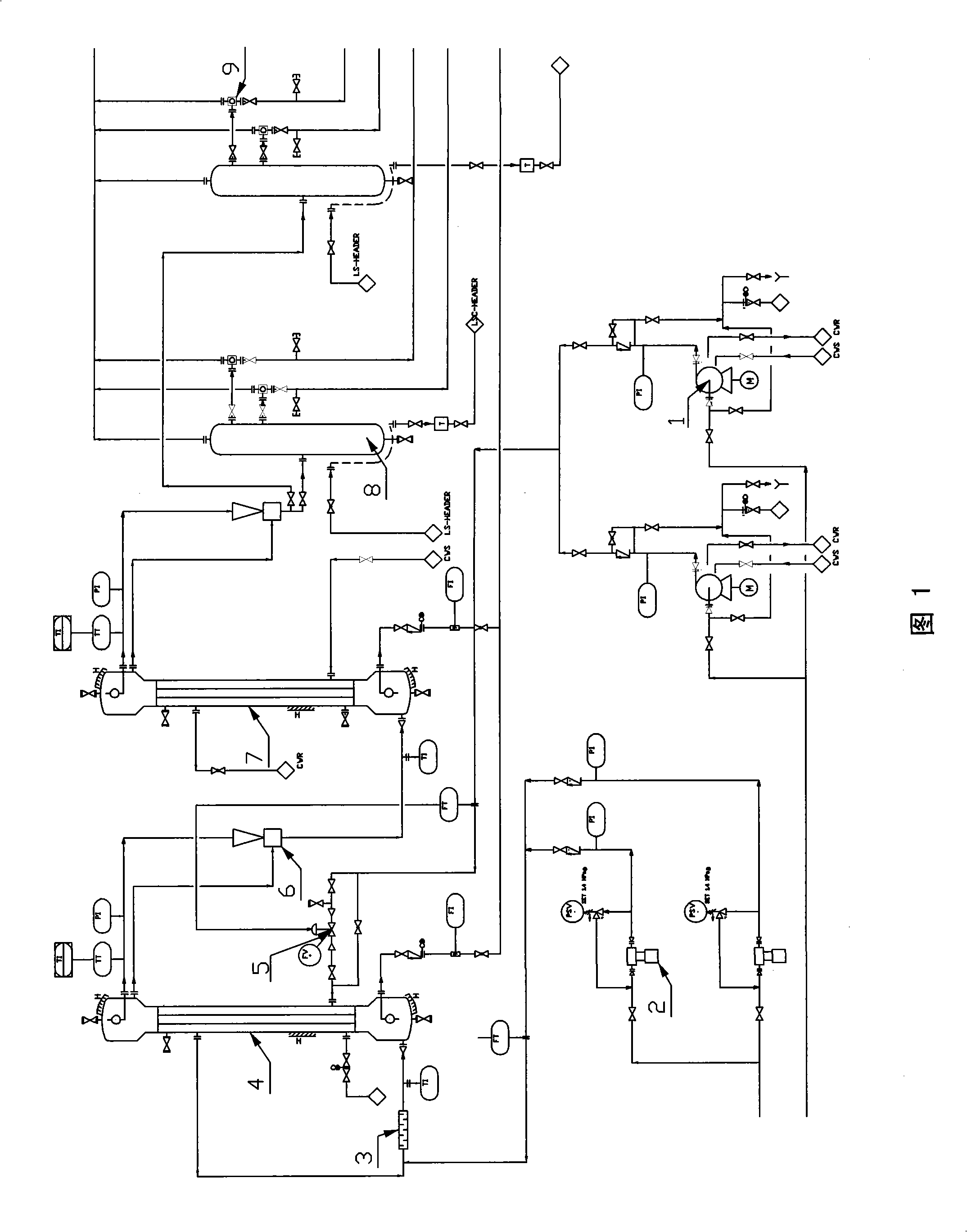

[0045] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0046] As shown in Figure 1, the new technological process of phenate decomposition of the present invention is characterized in that comprising the following steps:

[0047] (a) the sulfuric acid that net phenate and concentration are 40%~98% enters mixer in proportion, and weight ratio is net phenate: sulfuric acid=1: 0.6~1.2, flow velocity is 0.1~0.5m / s,

[0048] (b) The mixed liquid enters the 1# reactor 4 at a high speed, the flow rate is 1.5-2.5m / s, the reaction temperature: 100-150°C, the reaction pressure: 0.2-1.0MPa,

[0049](c) The gas phase and liquid phase produced by 1# reactor 4 enter 2# reactor 7 through the injector, the reaction temperature: 60~70℃, the reaction pressure: 0.1~0.5MPa,

[0050] (d) The reaction solution enters the separator 8 to separate the corresponding product crude phenol and sodium sulfate waste water....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com