Complete discharging wet grinding machine

A wet mill, a complete technology, applied in the field of wet mills, can solve the problems of poor material uniformity, affecting product quality, inconvenient discharging, etc., and achieve the effect of complete discharging, simple structure and convenient discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] The present invention will be further described below in conjunction with specific embodiments and drawings.

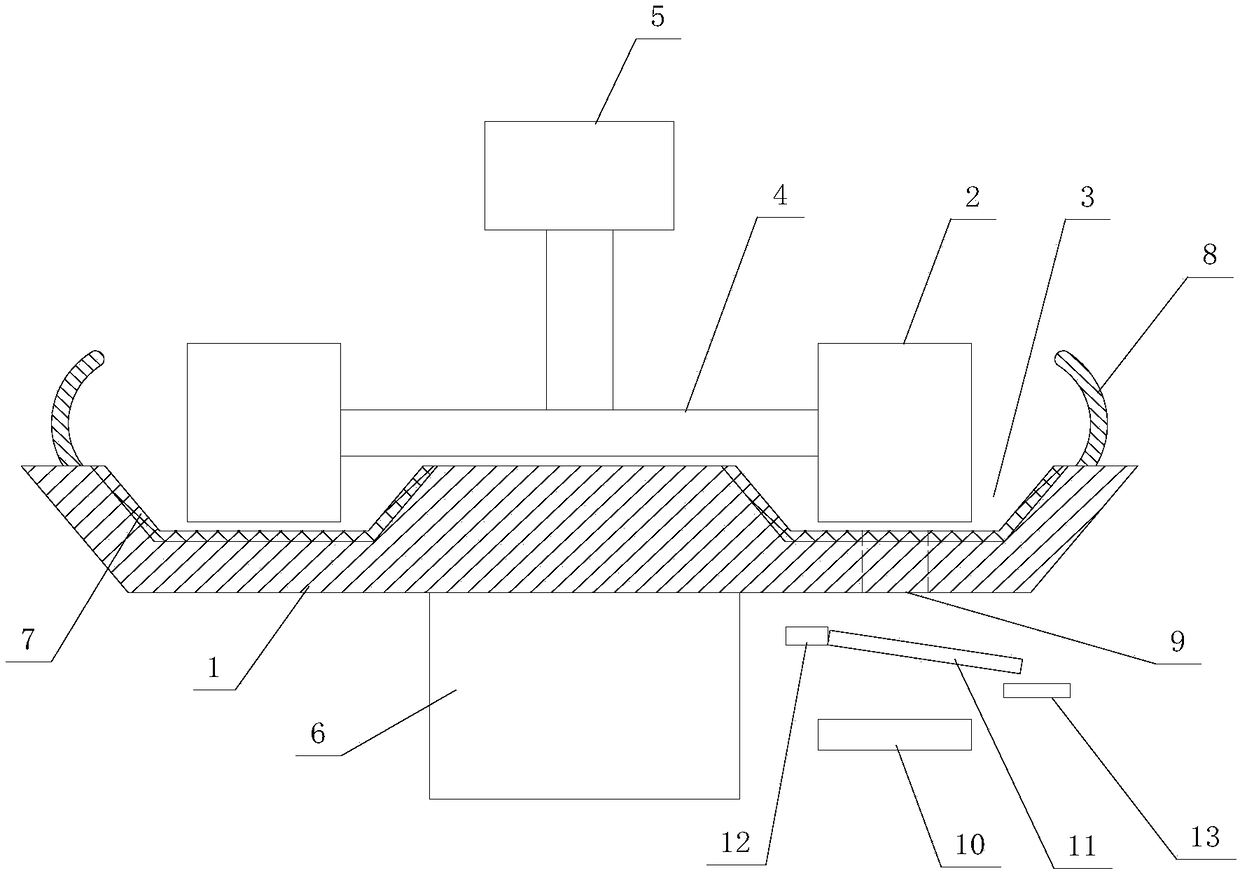

[0023] Such as figure 1 As shown, a wet grinding machine with complete discharge includes a grinding disc 1 and a grinding wheel 2. The grinding disc 1 is provided with a grinding trough 3, and two grinding wheels 2 are symmetrically arranged in the grinding trough 3, and the two grinding wheels 2 pass The horizontal link 4 is connected, and a rotating drive mechanism 5 is arranged above the horizontal link 4, the middle of the horizontal link 4 is connected with the rotating shaft of the rotating drive mechanism 5, and the bottom of the grinding pan 1 is fixed on the lifting platform 6.

[0024] The surface of the grinding trough 3 is provided with a wear-resistant ceramic layer 7. The top edge of the grinding trough 3 is provided with a baffle plate 8. The cross section of the baffle 8 is arc-shaped, and the curved concave surface faces the grinding trough 3.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com