Heating boiler with lifting pressing plate for crushing furnace slag

A technology for heating boilers and slag, applied in the field of boilers, can solve the problems of insufficient utilization of high-temperature flue gas heat energy, high cost of construction of a transmission pipeline network, and insufficient combustion of coal, so as to facilitate heat absorption and improve heat utilization rate. , the effect of avoiding personal burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

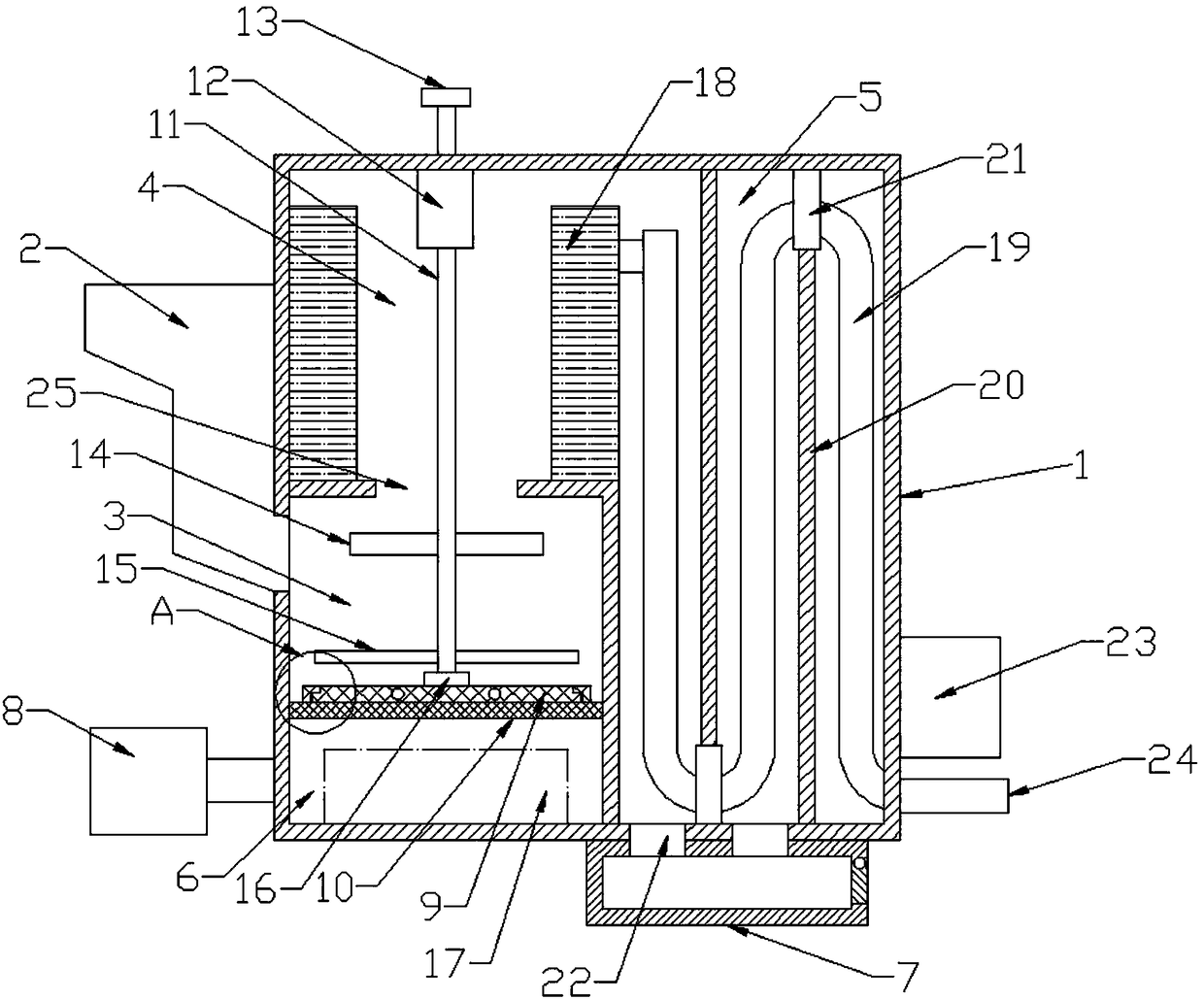

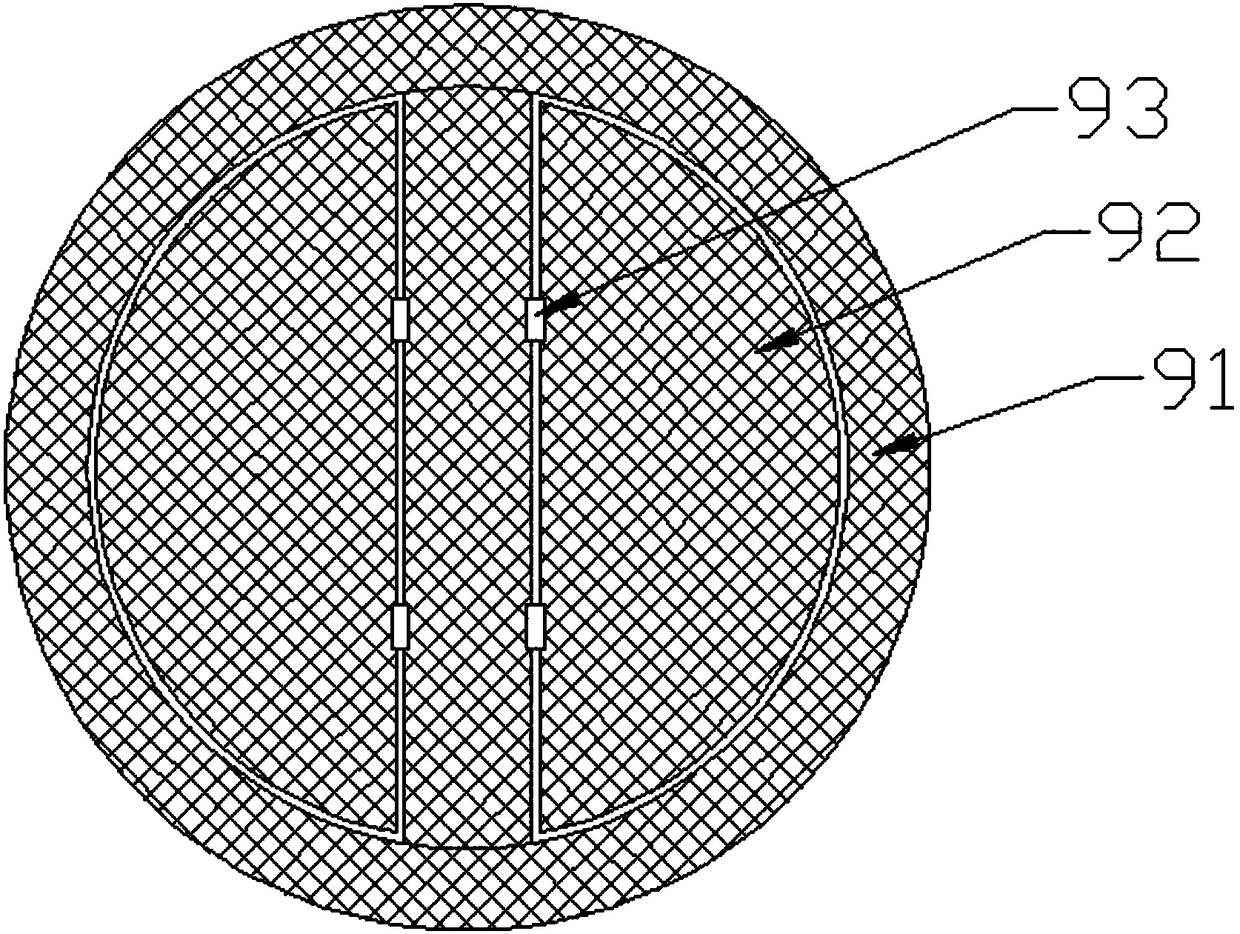

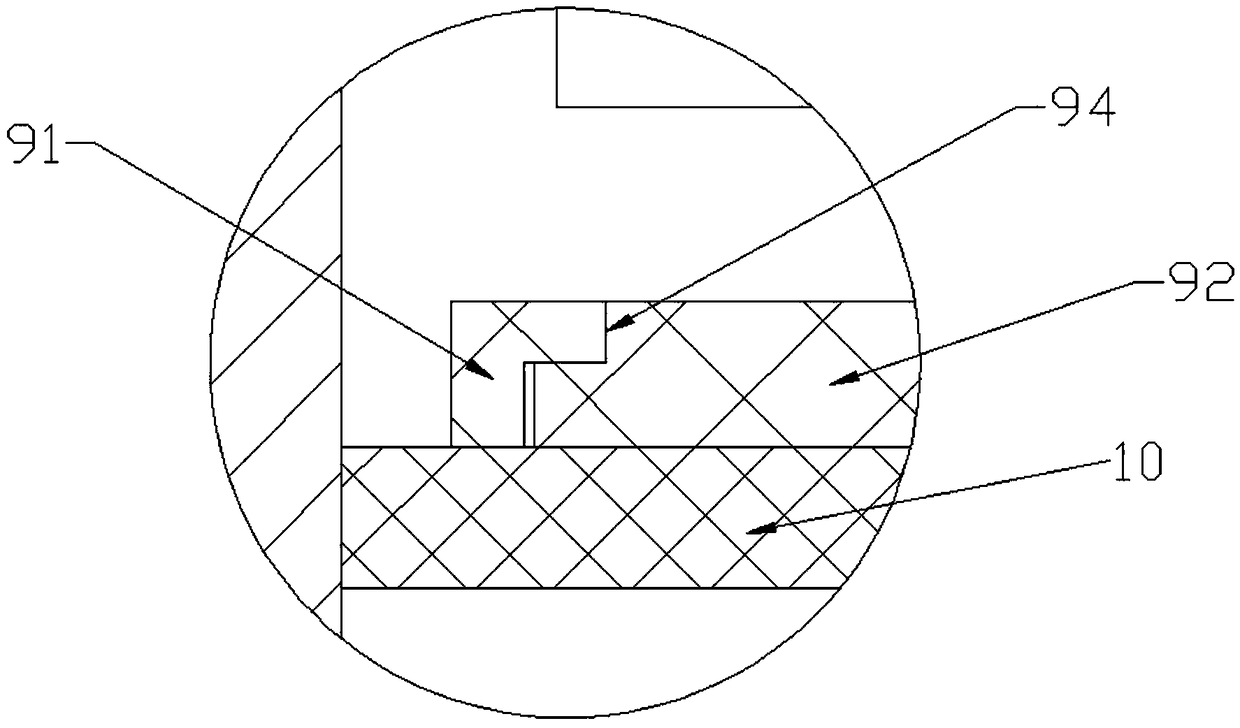

[0017] Please refer to the figure, in the embodiment of the present invention, a heating boiler with lifting pressure plate for pulverizing slag includes a shell 1, a feed hopper 2, a combustion chamber 3, a heating chamber 4 and a slag collection chamber 6; the shell 1 The interior is divided into a combustion chamber 3, a heating chamber 4, a slag collection chamber 6 and a flue 5, the combustion chamber 3 is located above the slag collection chamber 6, and a horizontal furnace grate 10 is fixed between the combustion chamber 3 and the slag collection chamber 6, The heating chamber 4 is located above the combustion chamber 3, and a heating port 25 is provided between the combustion chamber 3 and the heating chamber 4, so that the hot air and flue gas generated by combustion in the combustion chamber 3 enter the heating chamber 4, and the heating chamber 4 The upper end communicates with the flue 5.

[0018] The bottom of the slag collection chamber 6 is connected with a blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com