Construction method for high artesian area ultra-deep foundation pit

A construction method and technology of deep foundation pits, applied in infrastructure engineering, excavation, construction, etc., can solve problems such as large impact, slow sinking speed of bottom-sealed caissons, and difficult construction, so as to reduce engineering risks, protect the surrounding environment, The effect of saving engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

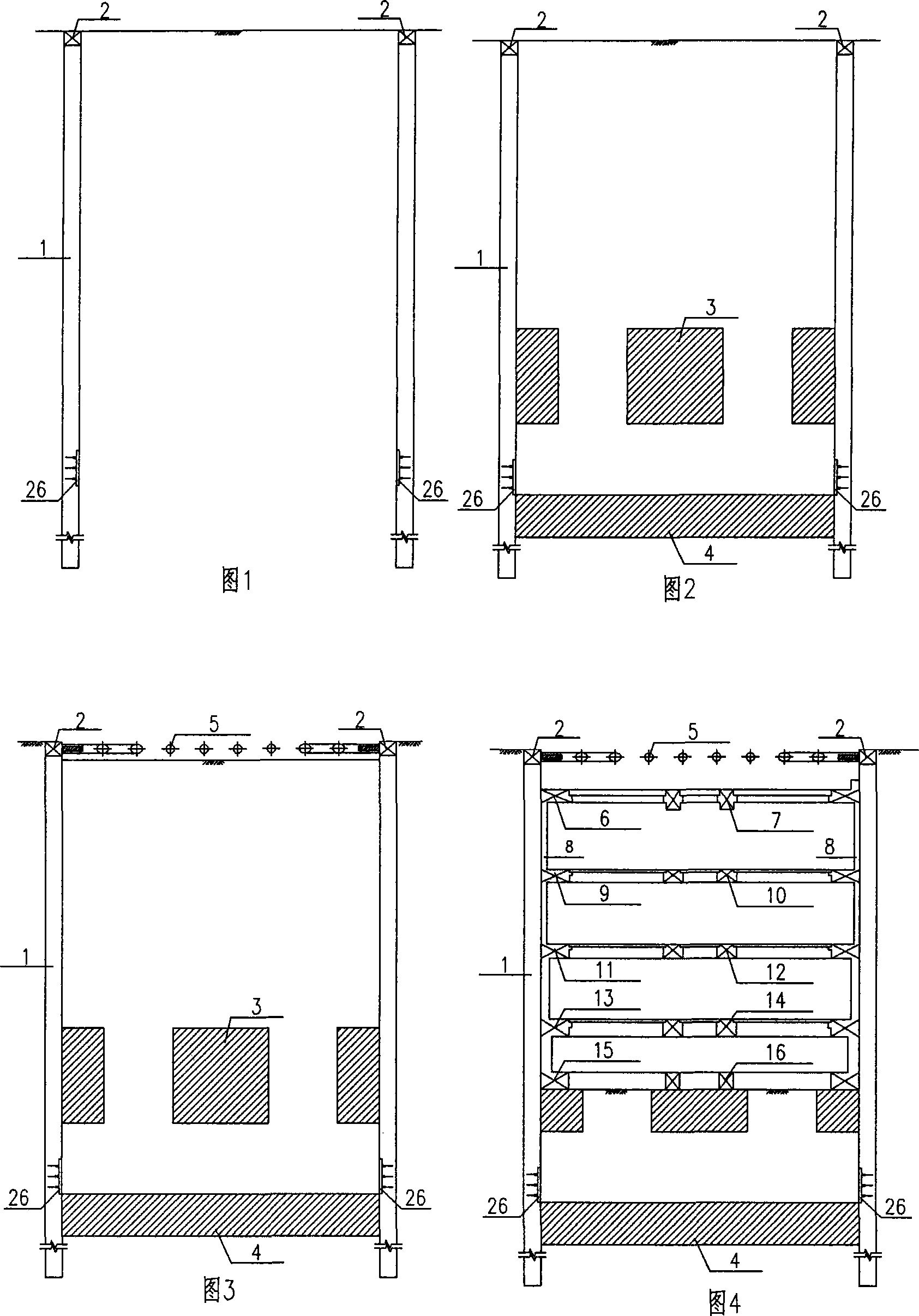

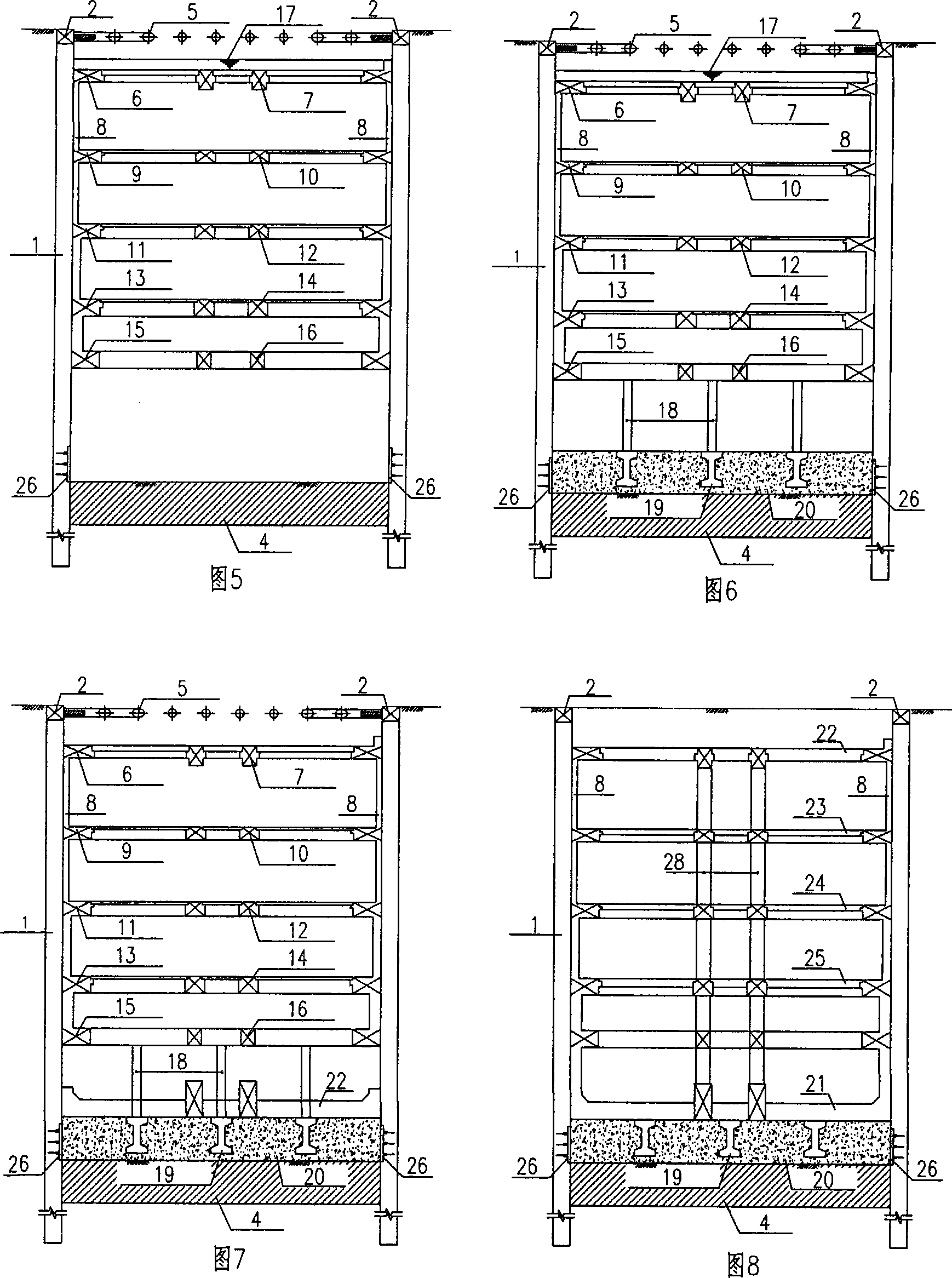

[0025] Embodiment: In this embodiment, underground diaphragm walls (or bored piles, occlusal piles, and corresponding water-proof curtains) are used as the enclosure structure, and internal supports (steel supports or concrete supports) are used as the support structure. Under the premise of the safety factor of the confined water, the open excavation construction is carried out to a certain elevation (that is, the confined water layer is not depressurized or the confined water head is only slightly reduced). The upper side wall, and then inject water into the foundation pit (the height of the water head is based on the fact that the excavation to the bottom of the pit can resist the pressurized water and meet a certain safety factor), and carry out underwater excavation construction. The floor elevation of the underwater excavation and exceed Dig a certain depth for underwater bottom sealing concrete pouring, then pump out the water in the foundation pit, pour the bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com