Method for preparing modified desulphurized ash

A desulfurization ash and modification technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor concrete stability, resource utilization restrictions of desulfurization ash, waste of resources, etc., to achieve The effects of eliminating poor stability of cement, solving resource utilization problems, and reducing clinker consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Application of modified desulfurization ash in cement production

[0018] First modify the desulfurization ash, including the following steps:

[0019] (1) Add water by spraying to the desulfurization ash with a free calcium oxide content of 12.32%, and make it fully mixed so that the water content of the desulfurization ash is 28%;

[0020] (2) Place in air with a humidity of 80% for 20 days for digestion to obtain modified desulfurization ash.

[0021] The content of free calcium oxide in the modified desulfurization ash was measured. In this embodiment, the content of free calcium oxide in the modified desulfurization ash was 2.83%.

[0022] The modified desulfurization ash prepared above is applied in cement production, and has good stability.

Embodiment 2

[0023] Example 2 Application of modified desulfurization ash in cement production

[0024] First modify the desulfurization ash, including the following steps:

[0025] (1) Add water to the desulfurization ash with a free calcium oxide content of 14.36%, stir to make it fully mixed, so that the water content of the desulfurization ash is 21%;

[0026] (2) Place in air with a humidity of 75% for 25 days for digestion to obtain modified desulfurization ash.

[0027] The content of free calcium oxide in the modified desulfurization ash was measured. In this embodiment, the content of free calcium oxide in the modified desulfurization ash was 3.18%.

[0028] The modified desulfurization ash prepared above is applied in cement production, and has good stability.

Embodiment 3

[0029] Embodiment 3 A kind of preparation of modified desulfurization ash

[0030] First modify the desulfurization ash, including the following steps:

[0031] (1) Add water to the desulfurization ash with a free calcium oxide content of 10.56%, stir to make it fully mixed, so that the water content of the desulfurization ash is 39%;

[0032] (2) Place in air with a humidity of 95% for 40 days for digestion to obtain modified desulfurization ash.

[0033] The content of free calcium oxide in the modified desulfurization ash was measured. In this embodiment, the content of free calcium oxide in the modified desulfurization ash was 2.56%.

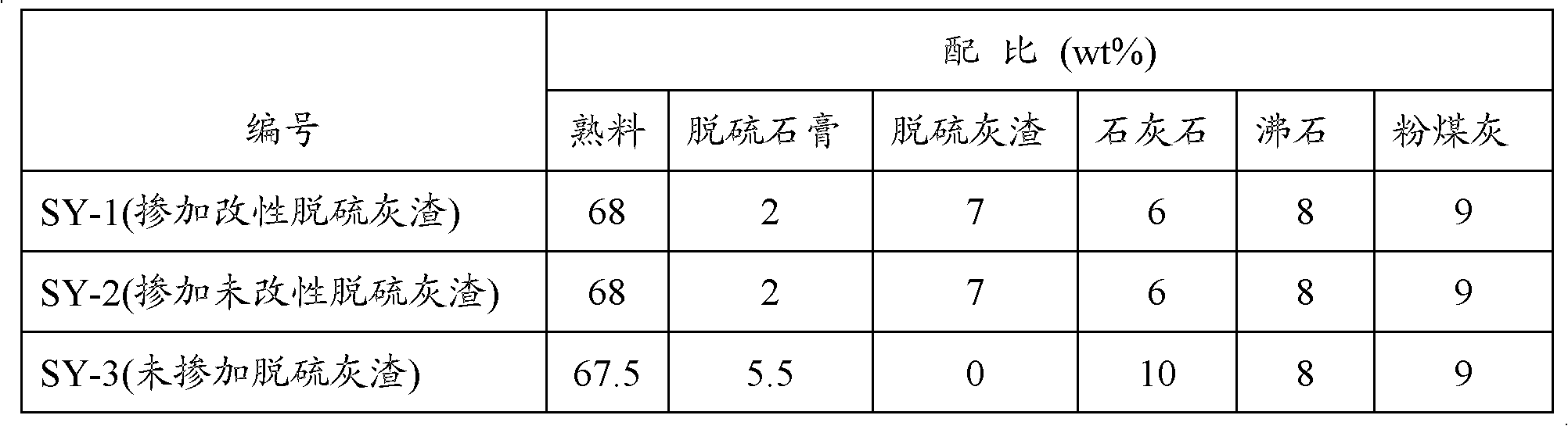

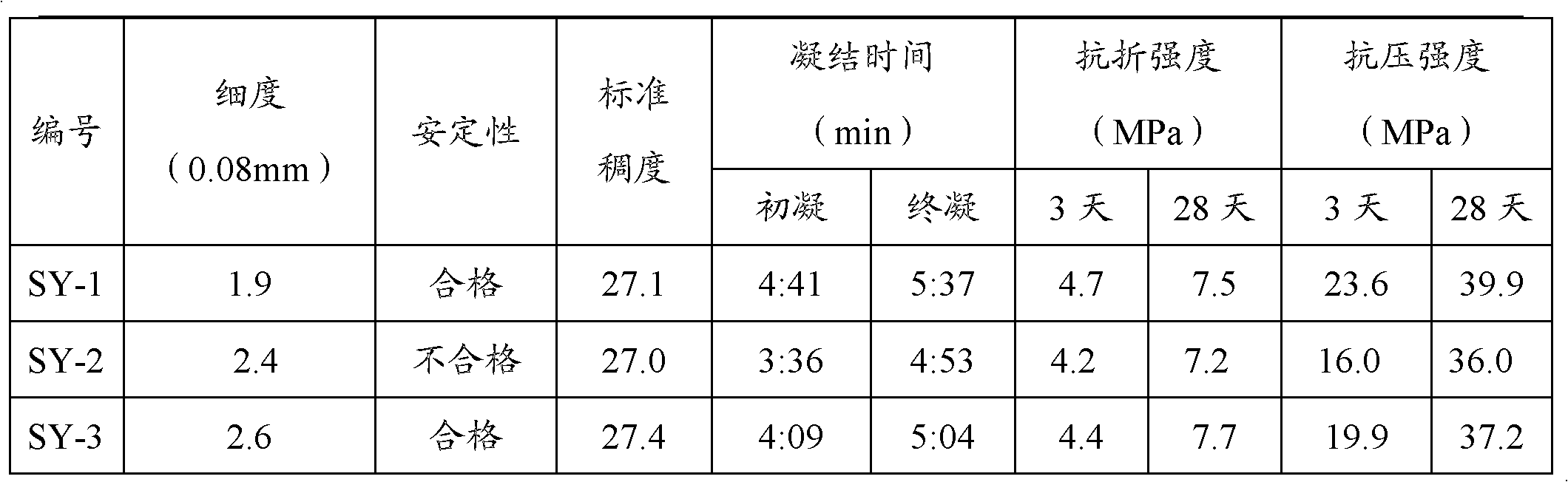

[0034] In the production of PC32.5 cement, the modified desulfurized ash obtained by mixing 7% of Example 3 is tested, compared with the cement produced by the normal formula and with the cement produced by the modified desulfurized ash of Example 1, The formulations of various cements are shown in Table 1.

[0035] The production formula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com