Method for preparing soil conditioner from molasses alcohol waste liquor

A technology of molasses alcohol waste liquid and soil improver, which is applied in the direction of microorganism-based methods, soil conditioning materials, chemical instruments and methods, etc., can solve problems such as eutrophication, suffocation of aquatic organisms, and pollute the environment, and achieve environmental protection, The effect of fertilizing the soil and promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

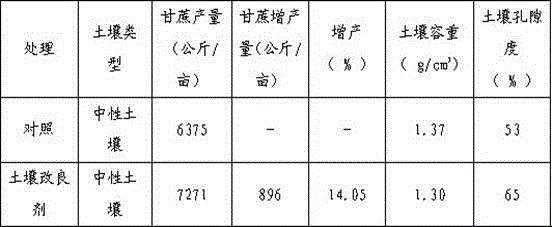

Examples

Embodiment 1

[0022] (1) Concentrate the molasses alcohol waste liquid to contain 38% organic matter (organic matter according to mass concentration ratio); P 0.84g / kg; K 35.12g / kg; Ca 5.55 g / kg; Mg 1.02g / kg; N 16.52g / kg; pH 4.2; Contains a small amount of sugar at the same time, and the concentrated Brix of molasses alcohol waste liquid is 35.

[0023] (2) Screening of yeast strains and preparation of fermented koji:

[0024] A. Selection of strains: ① Bacillus subtilis and Bacillus cereus are Gram-positive large bacilli with short or long chains. It has the following characteristics and advantages: the bacterium can exist in the form of spores under unfavorable environmental conditions, and has the characteristics of high temperature resistance (100 ° C), acid and alkali resistance, extrusion resistance and temperature change resistance, and meets the requirements of soil conditioner processing. The quality of the fertilizer is guaranteed. Bacillus subtilis can produce various enzymes ...

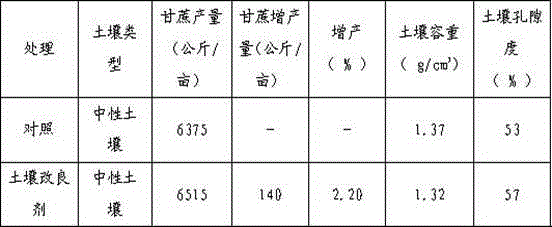

Embodiment 2

[0043] (1) Concentrate the molasses alcohol waste liquid to contain 45% organic matter (organic matter according to mass concentration ratio); P 0.90 g / kg; K 50.0 g / kg; Ca 29.0 g / kg; Mg 10.0 g / kg; N 35.0 g / kg; pH 4.5; Contains a small amount of sugar at the same time, and the concentrated Brix of molasses alcohol waste liquid is 40.

[0044] (2) Screening of yeast strains and preparation of fermented koji:

[0045] A. Selection of strains: select Bacillus subtilis, Streptomyces jingyang, and Saccharomyces cerevisiae as strains for fermenting koji.

[0046] B. Production of koji:

[0047] ① The inoculation of the strains is performed under sterile conditions, and the purified strains are inoculated onto the prepared medium; the strains produced thereafter are first-class seeds;

[0048] ②Amplification on a shaking table, inoculate the first-grade seeds into a 2000-ml Erlenmeyer flask, and cultivate and amplify the number of bacteria. It takes about 3-5 days to cultivate, and...

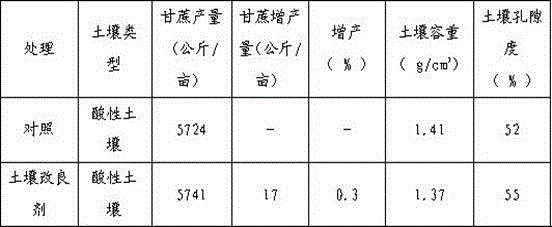

Embodiment 3

[0064] (1) Concentrate the molasses alcohol waste liquid to contain 51% organic matter (organic matter according to mass concentration ratio); P 1.98 g / kg; K 90.93 g / kg; Ca 39.90 g / kg; Mg 70.31 g / kg; N 50.40 g / kg; pH 5.1; Contains a small amount of sugar at the same time, and the concentrated Brix of molasses alcohol waste liquid is 50.

[0065] (2) Screening of fermentation strains and preparation of fermented koji,

[0066] A. Selection of strains: select Bacillus subtilis, Streptomyces jingyang, and Saccharomyces cerevisiae as strains for fermenting koji.

[0067] B, the production of koji:

[0068] ① The inoculation of strains is performed under sterile conditions, and the purified strains are inoculated on the prepared medium; the strains produced thereafter are first-class seeds.

[0069] ②Amplification on a shaking table, inoculate the first-grade seeds into a 2000-ml Erlenmeyer flask, and cultivate and amplify the number of bacteria. It takes about 3-5 days to culti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com