Nano cellulose extracted from shuck of xanthoceras sorbifolia and extraction method

A technology of nano-cellulose and cellulose fibers, which can be used in the fields of fiber raw material processing, textiles and papermaking, and can solve the problem of resource utilization of sorbiflora sorbifolium residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

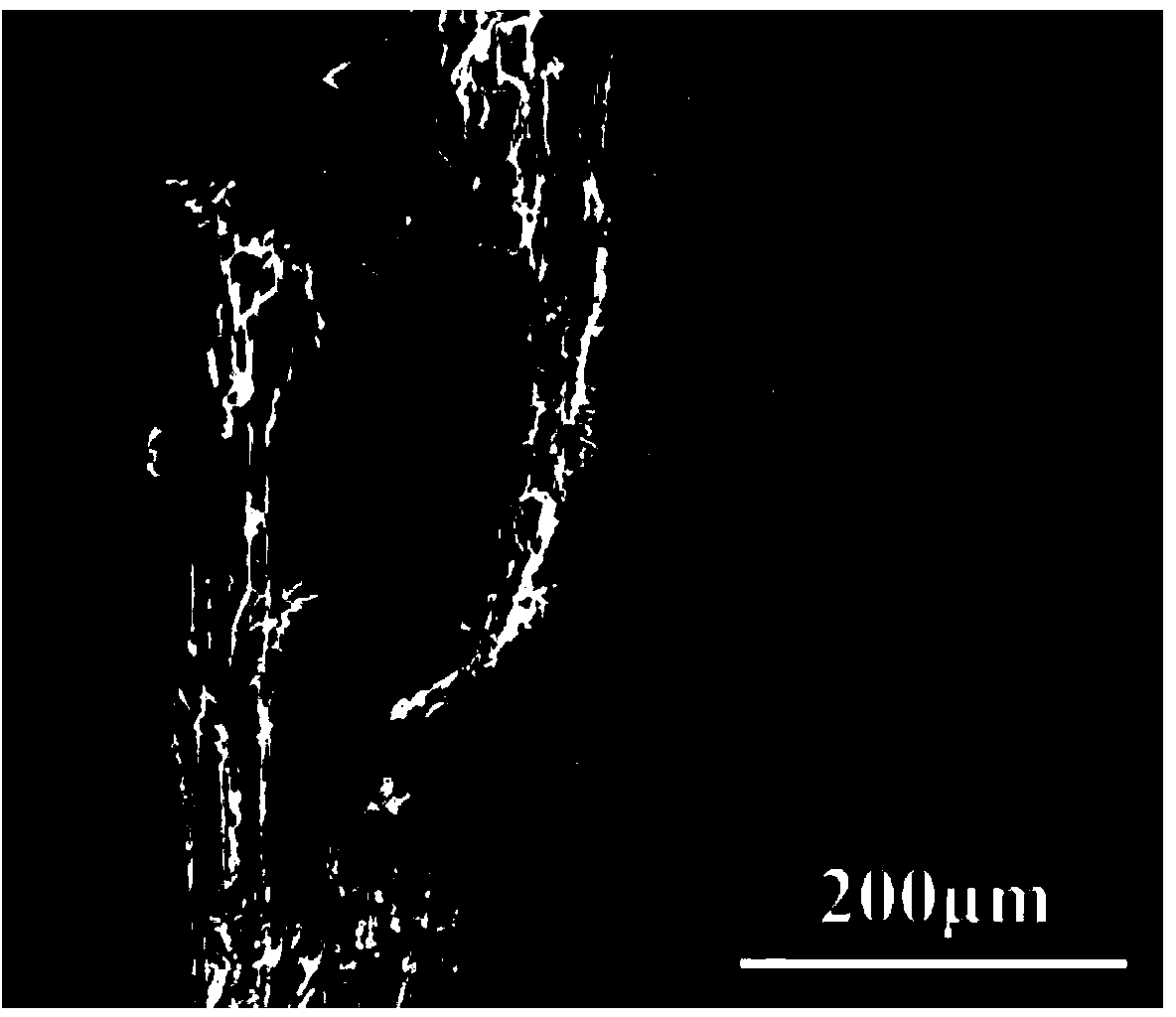

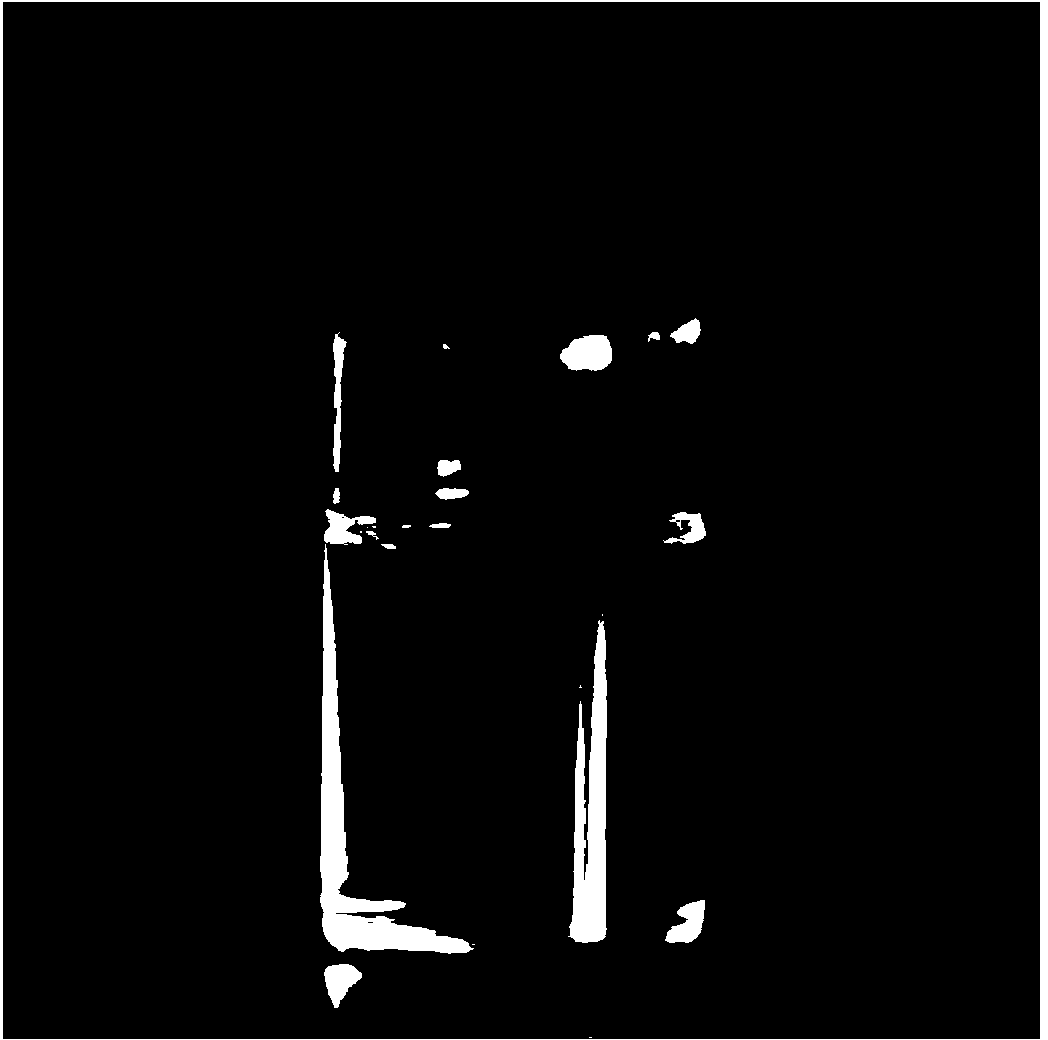

Image

Examples

Embodiment 1

[0018] Take 100g of crushed sorbifolia husks and immerse them in 5% sodium hydroxide solution for 12 hours, then wash them repeatedly until the pH becomes neutral, then put them into an oven and dry them at 60°C. Submerge the treated sorbifolia husk in a mixed solution of toluene and ethanol with a volume ratio of 1:1, heat the solution to a slight boiling state, and keep it for 6 hours. The residue was repeatedly washed with ethanol, put into an oven, and dried at 60°C.

[0019] Put the treated sorbifolia husk into a mixed solution of hydrogen peroxide (30%) and acetic acid with a volume ratio of 1:1, heat to 60°C and keep it under stirring for 7 hours to perform lignin removal treatment. The residue was washed with deionized water and suction filtered until the filtrate was neutral. In order to ensure the complete reaction, the above delignification step was repeated once, and then the obtained product was heated to 80°C in 5% sodium hydroxide solution to react for 2 hours,...

Embodiment 2

[0022] Take 200g of crushed sorbifolia husks and immerse them in a 3% sodium hydroxide solution for 24 hours, then wash them repeatedly until the pH becomes neutral, then put them into an oven and dry them at 50°C. Submerge the treated sorbifolia husk in a mixed solution of toluene and ethanol with a volume ratio of 1:0.5, heat the solution to a slight boiling state, and keep it for 12 hours. The residue was repeatedly washed with ethanol, put into an oven, and dried at a temperature of 50°C.

[0023] Put the treated sorbifolia husk into a mixed solution of hydrogen peroxide (30%) and acetic acid with a volume ratio of 1:1, heat it to 50°C and keep it under stirring for 9 hours to perform lignin removal treatment. The residue was washed with deionized water and suction filtered until the filtrate was neutral. In order to ensure the complete reaction, the above delignification step was repeated twice, and then the obtained product was heated to 60°C in 3% sodium hydroxide solu...

Embodiment 3

[0026] Take 300g of crushed sorbifolia husks and immerse them in a 10% sodium hydroxide solution for 8 hours, then wash them repeatedly until the pH becomes neutral, then put them into an oven and dry them at 80°C. Submerge the treated sorbifolia husk in a mixed solution of toluene and ethanol with a volume ratio of 1:2, heat the solution to a slight boiling state, and keep it for 12 hours. The residue was repeatedly washed with ethanol, then put into an oven, and dried at 80°C.

[0027] Put the treated sorbifolia husk into a mixed solution of hydrogen peroxide (30%) and acetic acid with a volume ratio of 1:2, heat it to 60°C and keep it under stirring for 12 hours to perform lignin removal treatment. The residue was washed with deionized water and suction filtered until the filtrate was neutral. In order to ensure the complete reaction, the above delignification step was repeated 3 times, and then the product obtained was heated to 80°C in 8% sodium hydroxide solution to rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com