Sea dredged silt dewatering and solidifying treatment integrated device and method

A technology for sludge dredging and solidification treatment, applied in fixed/solidified sludge treatment, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc. Long cycle and other problems, to solve the problem of disposal problems and efficient resource utilization, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

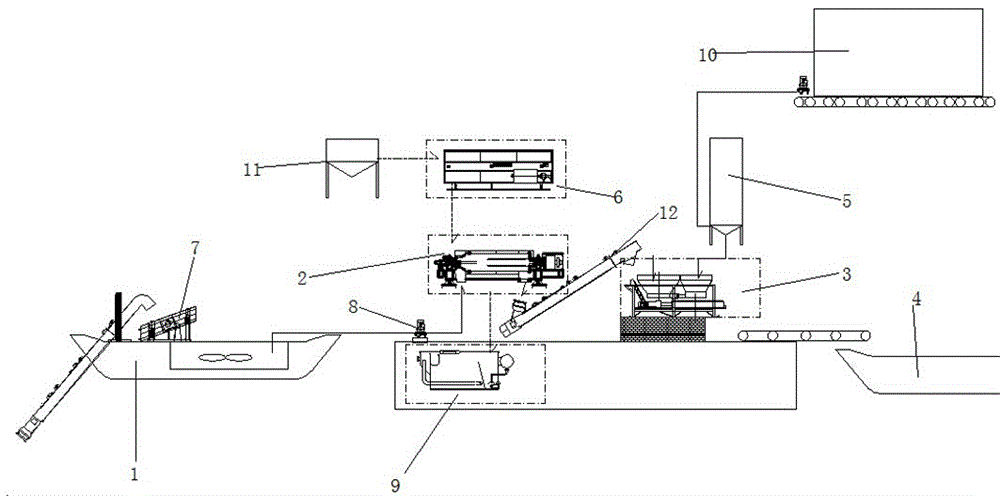

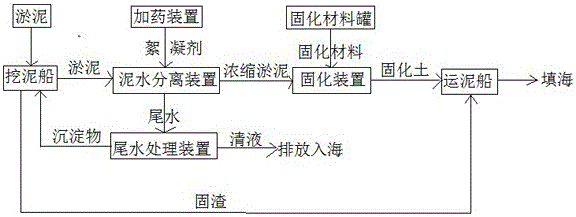

[0032] The structural schematic diagram of an integrated device for dehydration and solidification of marine dredging sludge in this embodiment is as followsfigure 1 As shown, it includes a dredger 1, an offshore processing platform and a dredging ship 4; the offshore processing platform is provided with a dredge pump 8, a dosing device 6, a mud-water separation device 2, a tail water treatment device 9, and a curing device 3 and two solidified material tanks 5, the dredge pump 8 is used to pump the mud in the cabin of the dredger 1 into the mud-water separation device 2, and the dosing device 6 is used to add the prepared flocculant into the mud-water separation device 2, and the muddy water The separation device 2 is provided with a tail water outlet and a sludge outlet, the tail water outlet is connected to the tail water treatment device 9, the sludge outlet is connected to the sludge inlet of the solidification device 3, and the solidified material tank 5 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com