Sludge/mud environment-friendly type baking-free bricks and preparation method thereof

An environmentally friendly, non-burning brick technology, used in sustainable waste treatment, solid waste management, climate sustainability, etc. The performance of brick products is unstable, prone to cracks or corners, etc., to avoid pollution transfer and secondary pollution, facilitate stirring and molding processing, and improve compressive and flexural strength, wear resistance, and freeze-thaw resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

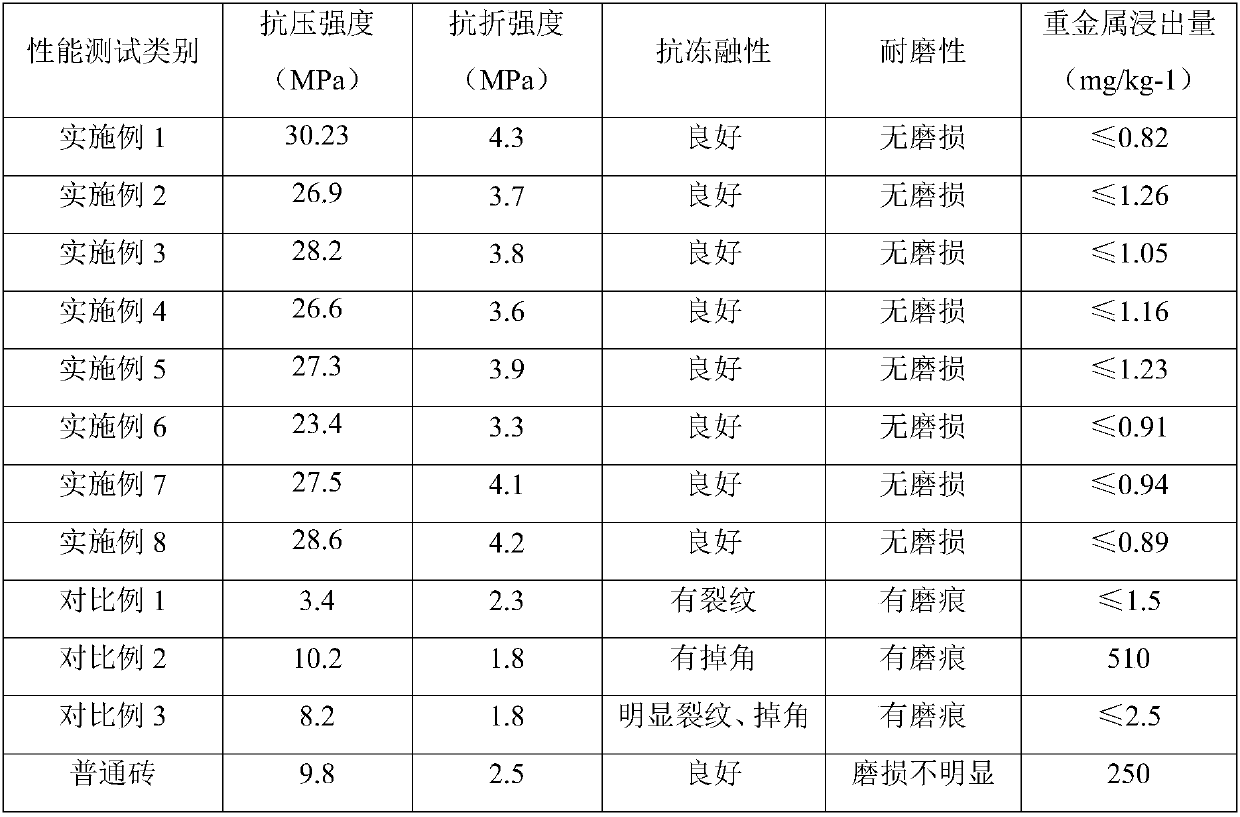

Examples

preparation example Construction

[0023] As a preferred embodiment, the preparation method of unfired bricks described in the following examples and comparative examples all include the following steps: 1. Measure the raw materials into the stirring container in sequence according to weight percentage; 2. Add 2 ~20% water is stirred and mixed evenly to obtain the mixture; Ⅲ. The mixture is pressed and formed by a hydraulic press to obtain bricks; Ⅳ. The molded bricks are first heated to 160-200°C under 0.62-1.57MPa and then steamed at a constant temperature for 4-8 hours; Ⅴ . Naturally lowering the temperature to prepare the sludge-environment-friendly non-burning brick. The process of the invention is simple and efficient, not affected by the temperature and humidity of the outside weather, the autoclave time is less than 12 hours, the temperature is moderate at 160-200° C., and the performance of the final product brick is stable.

[0024] The inventors found that adjusting within the parameters defined by t...

Embodiment 1

[0027] An environment-friendly sludge-free brick, comprising the following raw materials in weight percent: 40% of waste mud, 15% of coarse sand, 15% of silicon-aluminum-iron-calcium oxide, 10% of stone powder, 10% of quicklime, and 10% of gypsum;

[0028]Wherein, the waste sludge is treated with a special curing agent with a water content of 4%, and then filtered, dried, and roller-milled and then passed through a 100-mesh sieve; the silicon-aluminum-iron-calcium oxidized The substance is fly ash.

[0029] The special curing agent is a mixture of calcium oxide, cement, polyacrylamide and chitosan, and the content of chitosan is 3%.

[0030] The particle size of the silicon-aluminum-iron-calcium oxide is less than or equal to 1mm; the particle size of more than 80% of the coarse sand is 0.5-1mm; the stone powder is composed of discarded concrete, crushed stone or stone powder brick, and its particle size is between 3 ~ 7mm, the mud content is less than 2%.

[0031] The prepa...

Embodiment 2

[0033] A kind of sewage sludge environment-friendly burning-free brick, including the following raw materials in weight percentage: waste mud 50%, coarse sand 5%, silicon aluminum iron calcium oxide 22%, stone powder 8%, quicklime 13%, gypsum 2%;

[0034] Wherein, the waste sludge is treated with a special curing agent with a water content of 7%, and then passed through a 100-mesh sieve after pressure filtration, drying and roller grinding. The sugar content is 5%; the silicon-aluminum-iron-calcium oxide is fine coal slag.

[0035] The particle size of the silicon-aluminum-iron-calcium oxide is less than or equal to 1mm; the particle size of more than 80% of the coarse sand is 0.5-1mm; the stone powder is composed of discarded concrete, crushed stone or stone powder brick, and its particle size is between 3 ~ 7mm, the mud content is less than 2%.

[0036] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com