Method and equipment for producing organic mixed fertilizers by comprehensive utilization of wastes in sugar factory

A mixed fertilizer and organic technology, which is applied in the field of comprehensive utilization of sugar mill waste to produce organic mixed fertilizer, can solve the problems of complicated operation, inability to fully utilize sugar mills comprehensively, and cumbersome process of producing fertilizer production from waste, achieving less power consumption and realizing cleanliness. Production, the effect of promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

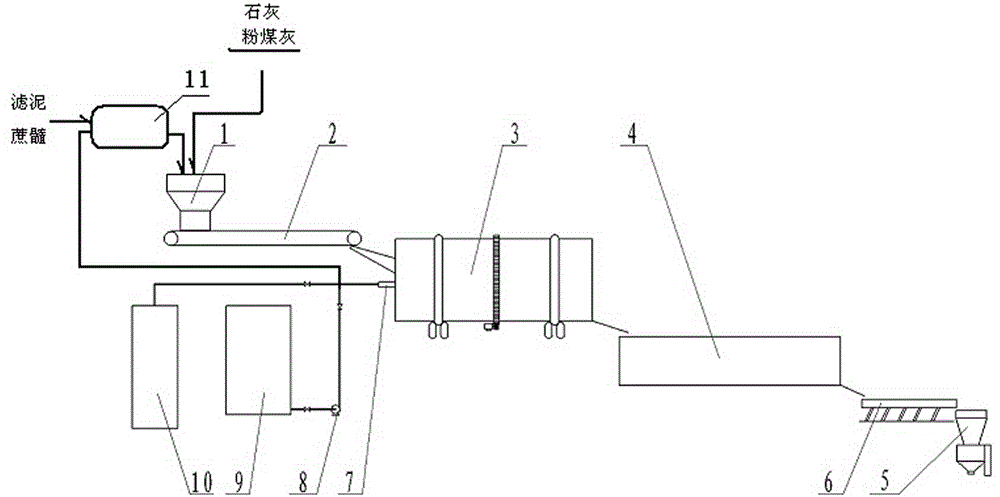

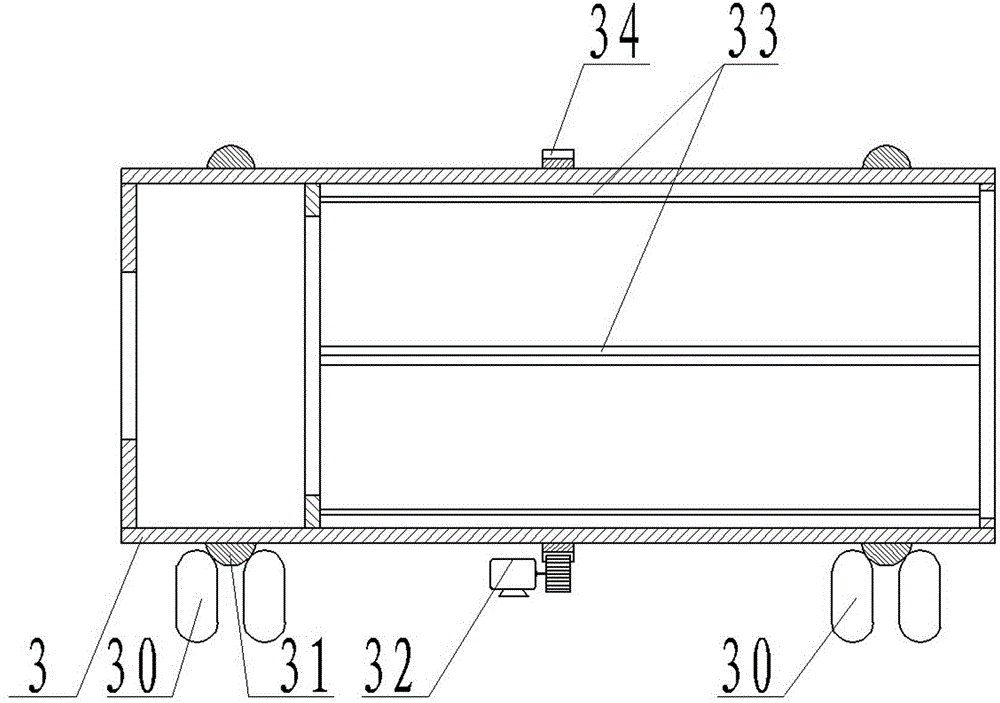

[0033] The equipment for the comprehensive utilization of sugar factory waste to produce organic mixed fertilizer includes a hopper 1, a conveyor belt 2, an alcohol waste liquid feeding device, a drum granulator 3, a dryer 4, a screening machine 6 and a packaging machine 5; in front of the hopper 1 or A pre-mixer 11 is provided above to mix the alcohol waste liquid with sugarcane pith and filter mud in advance; the hopper 1 is provided with an agitator, and the hopper 1 is arranged above the conveyor belt 2; the conveyor belt 2 and the alcohol waste liquid The feeding device is connected to the inlet of the drum granulator 3, and the outlet of the drum granulator 3 is connected to the dryer 4, the screening machine 6 and the packaging machine 5 in turn, and the drum granulator 3 includes a cylinder, a motor 32, and a supporting wheel 30 The inside of the cylinder is provided with a turning plate 33 and a baffle plate. The turning plate 33 is 3 pieces of angle steel evenly distr...

Embodiment 2

[0036] The equipment for the comprehensive utilization of sugar factory waste to produce organic mixed fertilizer includes a hopper 1, a conveyor belt 2, an alcohol waste liquid feeding device, a drum granulator 3, a dryer 4, a screening machine 6 and a packaging machine 5; in front of the hopper 1 or A pre-mixer 11 is provided above to mix the alcohol waste liquid with sugarcane pith and filter mud in advance; the hopper 1 is provided with an agitator, and the hopper 1 is arranged above the conveyor belt 2; the conveyor belt 2 and the alcohol waste liquid The feeding device is connected to the inlet of the drum granulator 3, and the outlet of the drum granulator 3 is connected to the dryer 4, the screening machine 6 and the packaging machine 5 in turn, and the drum granulator 3 includes a cylinder, a motor 32, and a supporting wheel 30 , the inside of the cylinder is provided with a turning plate 33 and a baffle plate. The turning plate 33 is 4 pieces of angle steel evenly dis...

Embodiment 3

[0039] The equipment for the comprehensive utilization of sugar factory waste to produce organic mixed fertilizer includes a hopper 1, a conveyor belt 2, an alcohol waste liquid feeding device, a drum granulator 3, a dryer 4, a screening machine 6 and a packaging machine 5; in front of the hopper 1 or A pre-mixer 11 is provided above to mix the alcohol waste liquid with sugarcane pith and filter mud in advance; the hopper 1 is provided with an agitator, and the hopper 1 is arranged above the conveyor belt 2; the conveyor belt 2 and the alcohol waste liquid The feeding device is connected to the inlet of the drum granulator 3, and the outlet of the drum granulator 3 is connected to the dryer 4, the screening machine 6 and the packaging machine 5 in turn, and the drum granulator 3 includes a cylinder, a motor 32, and a supporting wheel 30 , the inside of the cylinder is provided with a turning plate 33 and a baffle plate. The turning plate 33 is 5 pieces of angle steel evenly dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com