Method and device for respectively extracting and using inorganic matters in sludge

An inorganic matter and sludge technology, applied in the direction of inorganic chemistry, sludge treatment, chemical instruments and methods, etc., can solve the problems of waste of inorganic matter resources, serious secondary pollution, etc., and achieve improved utilization rate, less impurity content, and high purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

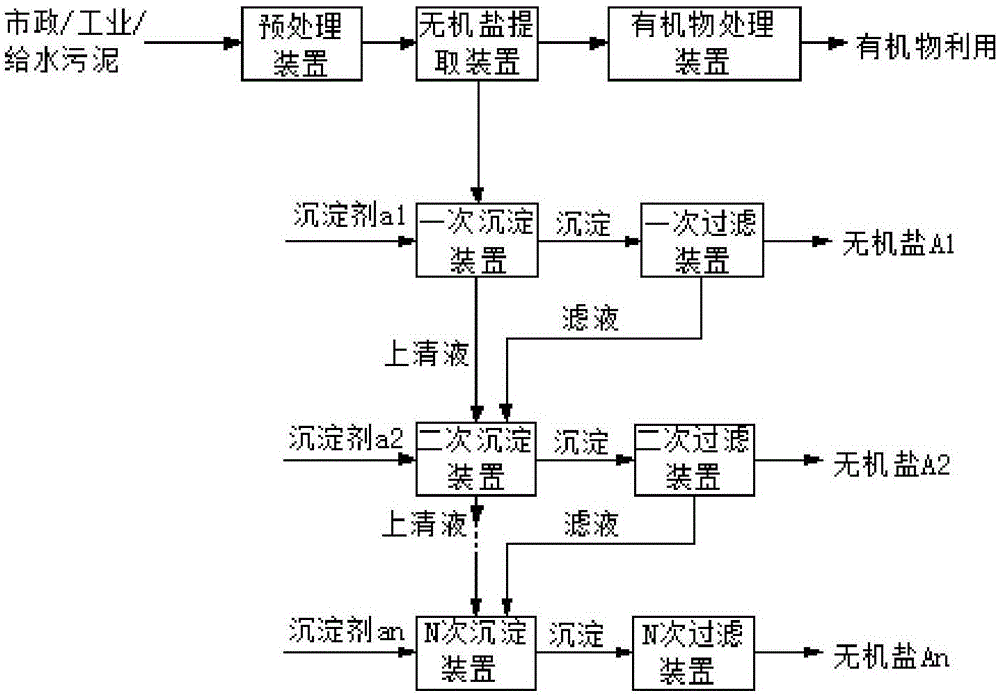

[0048] A device for separately extracting and utilizing inorganic substances in sludge, including a pretreatment device, an inorganic salt extraction device, a primary sedimentation device and a primary filtration device connected in sequence, the primary sedimentation device is connected with the secondary sedimentation device, and the secondary sedimentation device It is connected with the secondary filtering device, and also includes an organic matter treatment device, which is connected with the inorganic salt extraction device.

[0049] The specific implementation process is as follows:

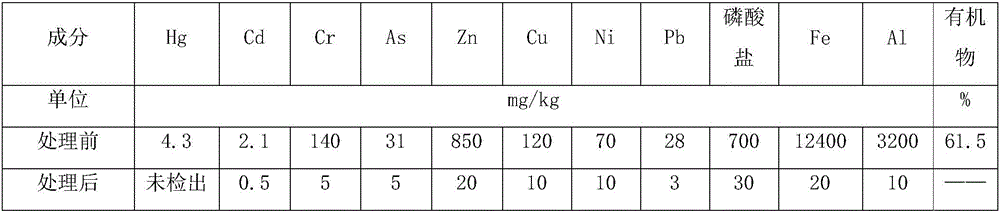

[0050] The sludge used comes from a water supply plant with a water content of 80%. Among the components of the sludge sample for analysis, the iron ion concentration is 1.7g / L, and the aluminum ion concentration is 9.4g / L. Pass the sludge into the pretreatment device, adjust the sludge into a sludge solution with a water content > 85%, add an acidic solution to the sludge solution for p...

Embodiment 2

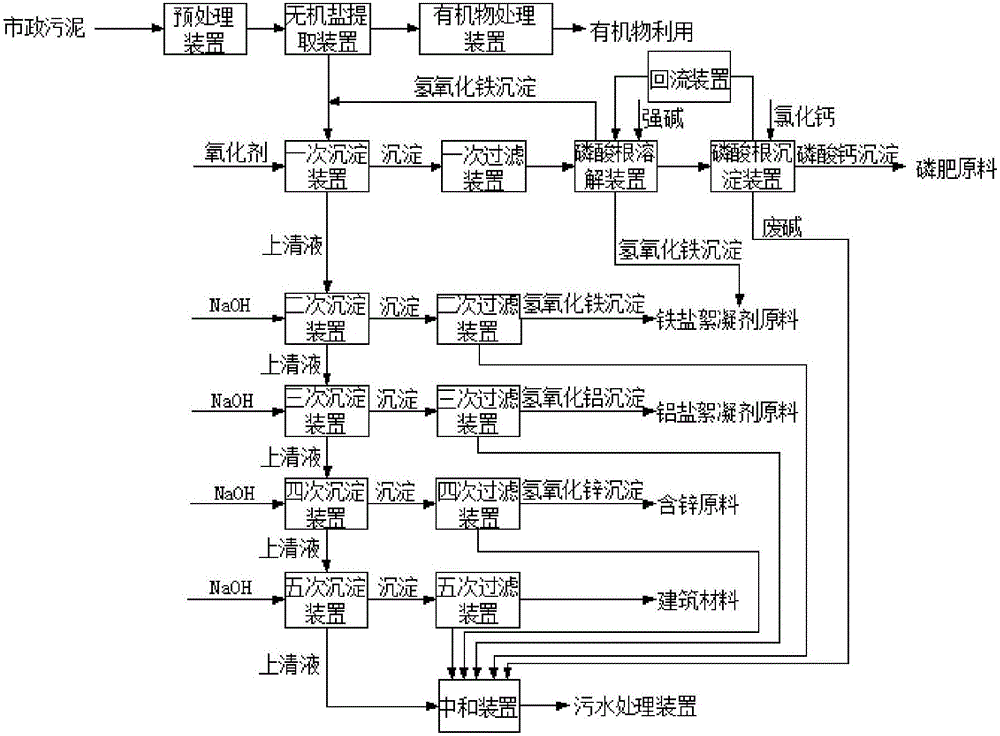

[0052] Such as figure 2 As shown, a device for separately extracting and utilizing the inorganic substances in the sludge, including a pretreatment device, an inorganic salt extraction device, a primary sedimentation device and a primary filtration device connected in sequence, the primary sedimentation device is connected with the secondary sedimentation device, and the secondary sedimentation device is connected in sequence. The secondary precipitation device is connected with the secondary filtration device, the secondary precipitation device is connected with the tertiary precipitation device, the tertiary precipitation device is connected with the tertiary filtration device, the tertiary precipitation device is connected with the fourth precipitation device, and the fourth precipitation device is connected with the fourth filtration device, The fourth settling device is connected with the fifth settling device, the fifth settling device is connected with the fifth filteri...

Embodiment 3

[0058] A device for separately extracting and utilizing inorganic substances in sludge, including a pretreatment device, an inorganic salt extraction device, a primary sedimentation device and a primary filtration device connected in sequence, the primary sedimentation device is connected with the secondary sedimentation device, and the secondary sedimentation device It is connected with the secondary filtration device, the secondary precipitation device is connected with the tertiary precipitation device, the tertiary precipitation device is connected with the tertiary filtration device, the tertiary precipitation device is connected with the fourth precipitation device, the fourth precipitation device is connected with the fourth filtration device, and the fourth precipitation device is connected with the fourth precipitation device. The device is connected with the fifth sedimentation device, and the fifth sedimentation device is connected with the fifth filtration device, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com