Apparatus for preparing CVD diamond film for linear sample

A technology for sample preparation and diamond film, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve problems such as low utilization rate of mixed gas, inability to generate uniform high-quality diamond film, etc., and achieve convenient replacement. , the effect of improving utilization and increasing growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

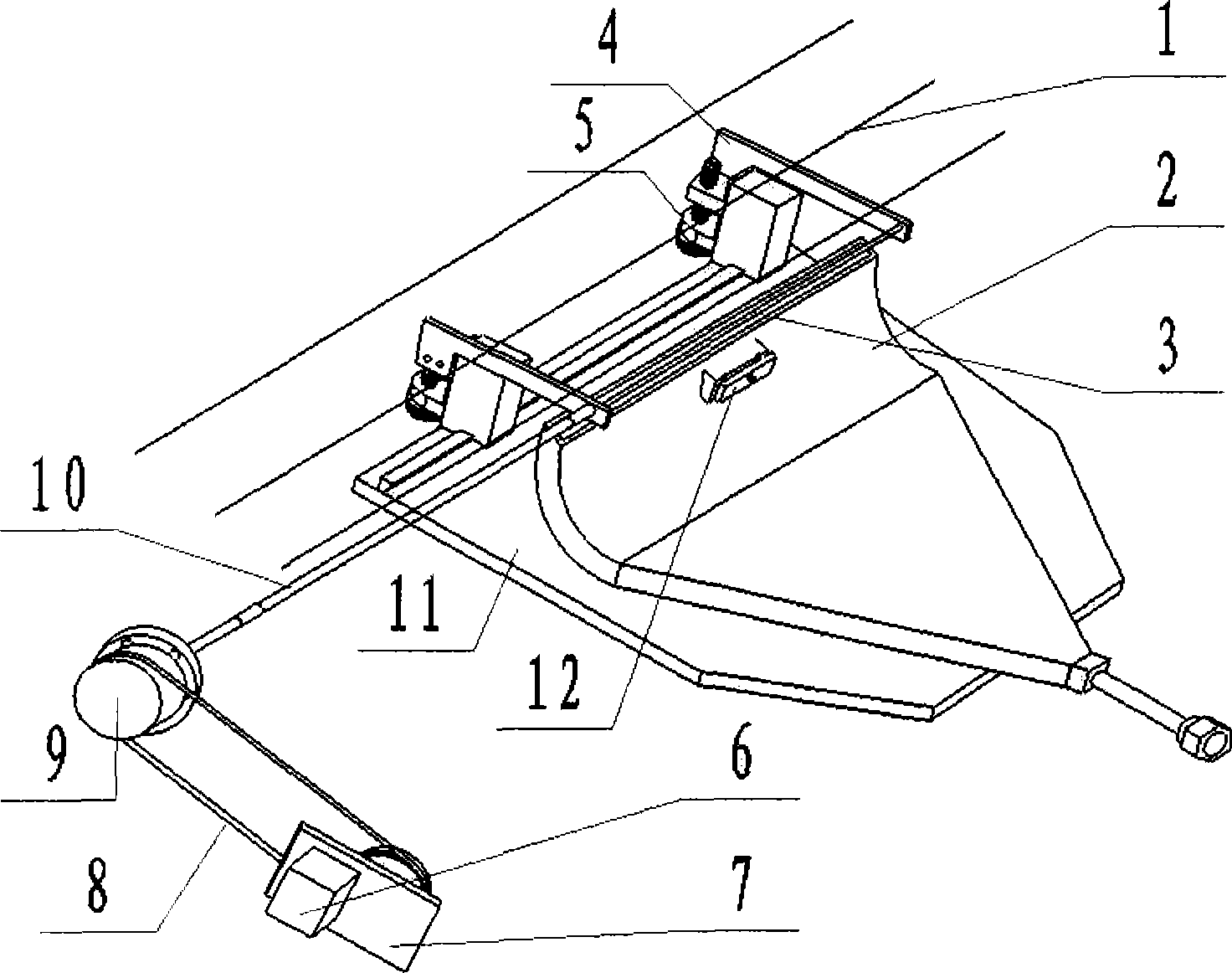

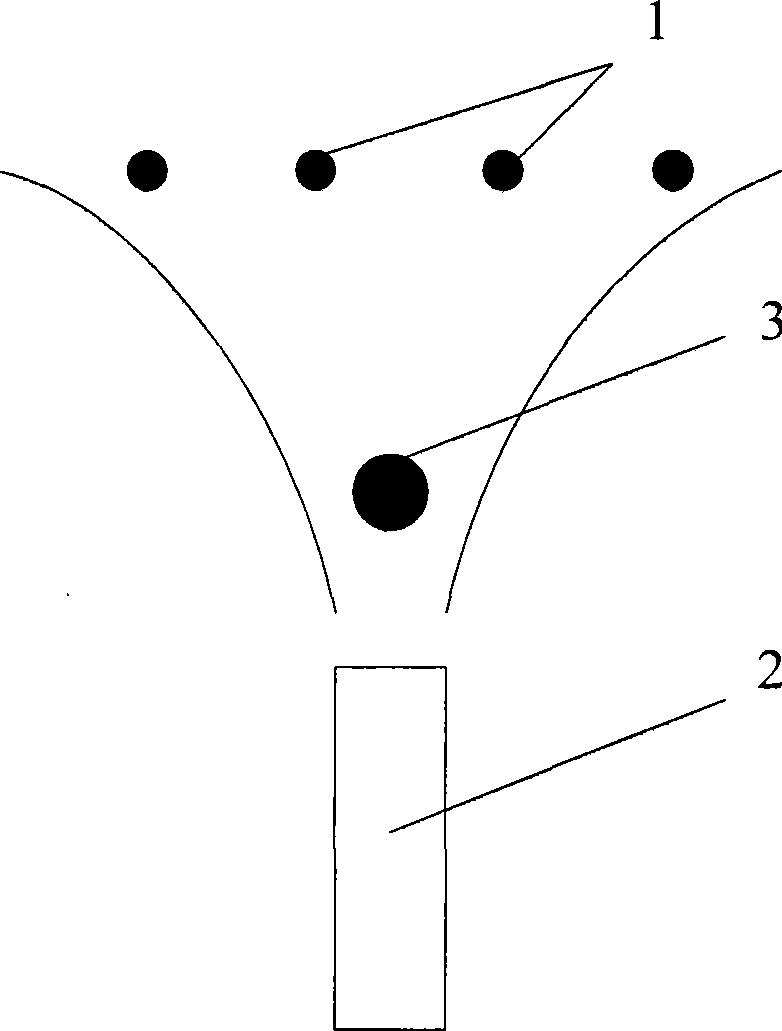

[0038] Such as figure 1 , figure 2 As shown, the device includes a gas collector 2, a substrate support frame 4, a displacement regulator 5, and a transmission device outside the vacuum equipment cavity, wherein the transmission device outside the vacuum equipment cavity consists of a stepping motor 6, a reduction box 7, a belt 8, The vacuum rotary valve 9 and the transmission flexible shaft 10 are formed. The gas collector 2 is a device made of stainless steel through bending and welding with a narrow slit ventilation cavity inside. The base supporting frame 4 is made of Mo, W, Ti or their alloys with high temperature resistance and small deformation coefficient. The displacement adjuster can precisely adjust the horizontal and vertical position of the linear base. The transmission device outside the chamber of the vacuum equipment is powered by the outside of the chamber, and the power is transmitted to the vacuum reaction chamber through the vacuum rotary valve 9, and ...

Embodiment 2

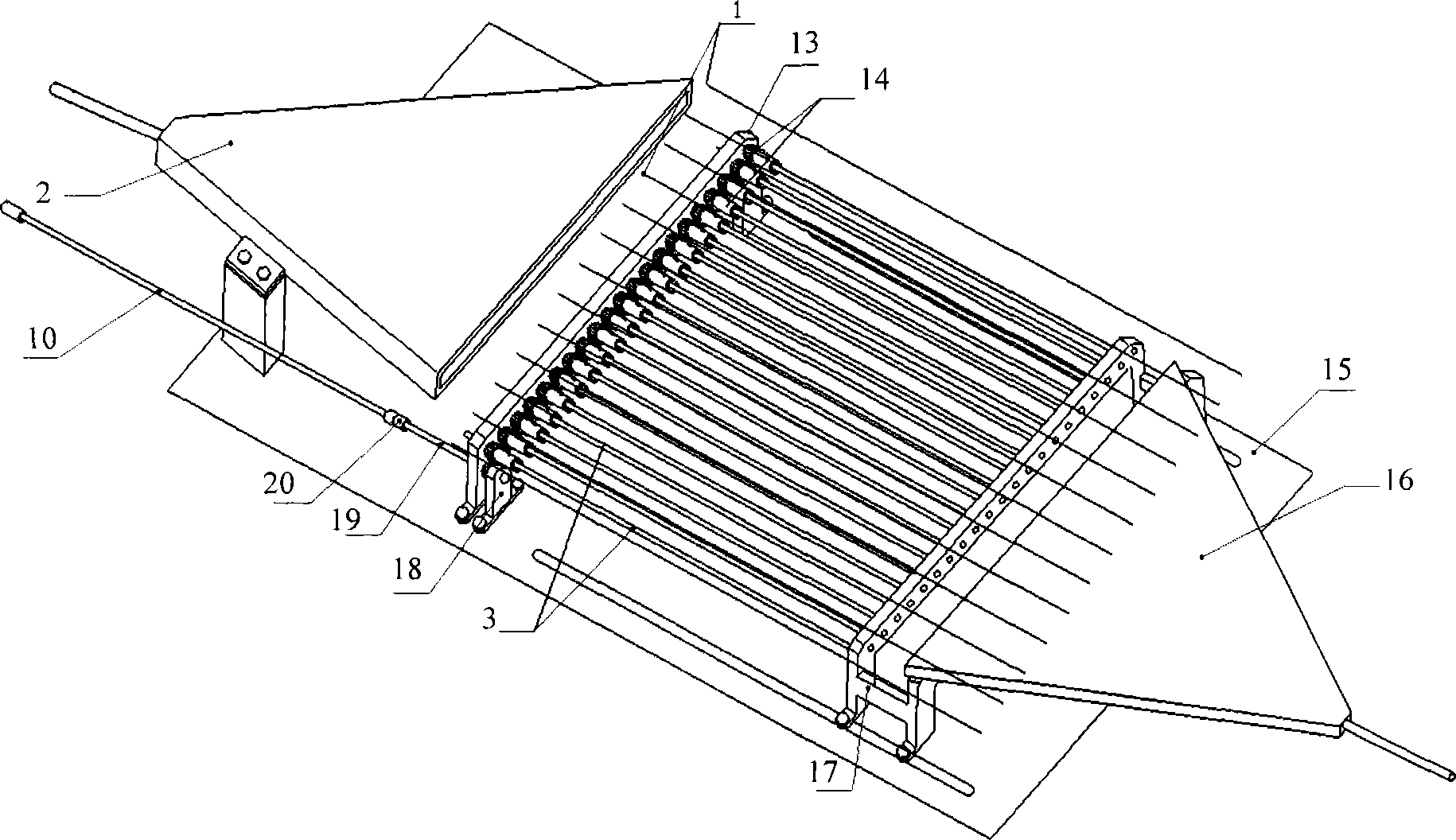

[0042] Embodiment 2: as image 3 As shown, the gas inlet device 16 and the gas collector 2 adopt the structure when they are arranged horizontally. The stratosphere evenly passes through multiple pieces of linear substrates 3 parallel to it, so that the reactant gas bundles are concentrated in a smaller area. The gas inlet device 16 and the gas collector 2 should be at a certain distance away from the fixed and movable support frames, so as to reduce the disturbance of the air flow field caused by the support frames blocking the flow direction of the air flow and the rotation of the gears. After the transmission system outside the vacuum chamber transmits power to the chamber, it connects the transmission flexible shaft 10 and drives the driving gear and the shaft 19 to rotate, so that the driven gear set 14 that meshes with each other drives the linear base 3 to rotate. The movable supporting frame 17 moves along the groove on the supporting plate 15, and the distance is adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com