Solid wood composite plate of fiber reinforced structure and preparation method of solid wood composite plate

A fiber-reinforced, solid wood composite technology, used in plywood presses, veneer manufacturing, wood veneer bonding, etc., can solve problems such as deformation, adhesive surface opening, panel cracking, etc. Stable, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

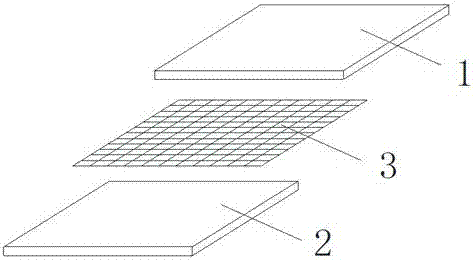

[0044] Such as figure 1 As shown, solid wood composite panels with fiber reinforced structures, including:

[0045] The face plate 1 and the base plate 2 stacked up and down, and a reinforcement layer 3 is arranged between them,

[0046] The panel 1, the base plate 2, and the reinforcement layer 3 are bonded by PUR glue.

[0047] In the above scheme, the PUR (Polyurethane Reactive) glue, the full name of the moisture curing reactive polyurethane hot melt adhesive, is a variety of solid hot melt adhesive, and its mechanism of action is: the polyurethane prepolymer reacts with the moisture in the air, Curing crosslinks to form a stable chemical structure. The glue does not contain water during the whole process, and the pressing process does not require a heat source.

[0048] In the above solution, the solid wood composite board includes but is not limited to solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com