Framework-taking optical fiber ring detaching device of optic fiber gyroscope

A technology for dismantling devices and fiber optic gyroscopes, which is applied to Sagnac effect gyroscopes, etc., can solve the problems of phase noise generated by the receiver, unsatisfactory results, time-consuming and labor-intensive problems, and achieve high pass rate, easy processing, and flexible applications change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

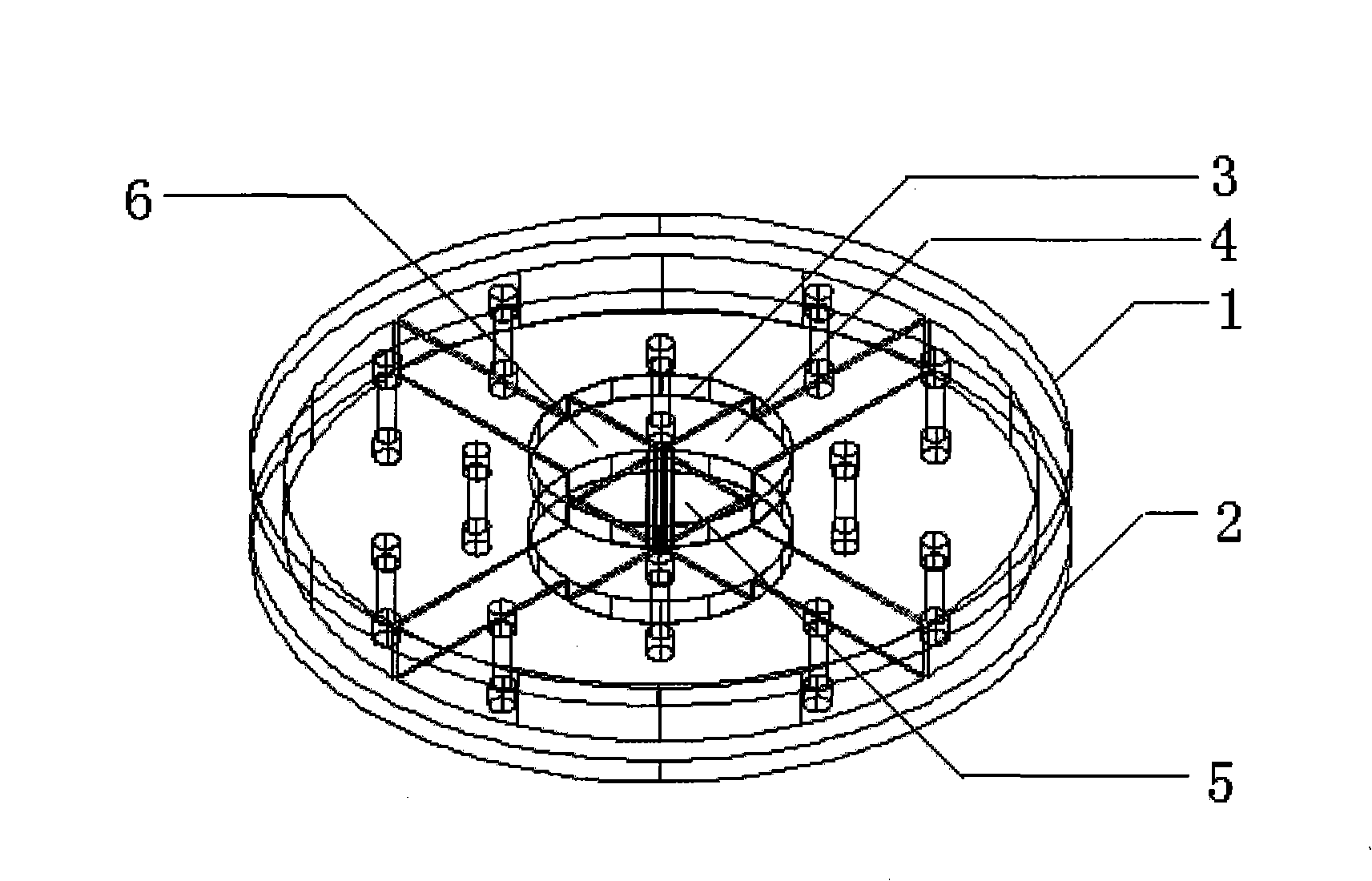

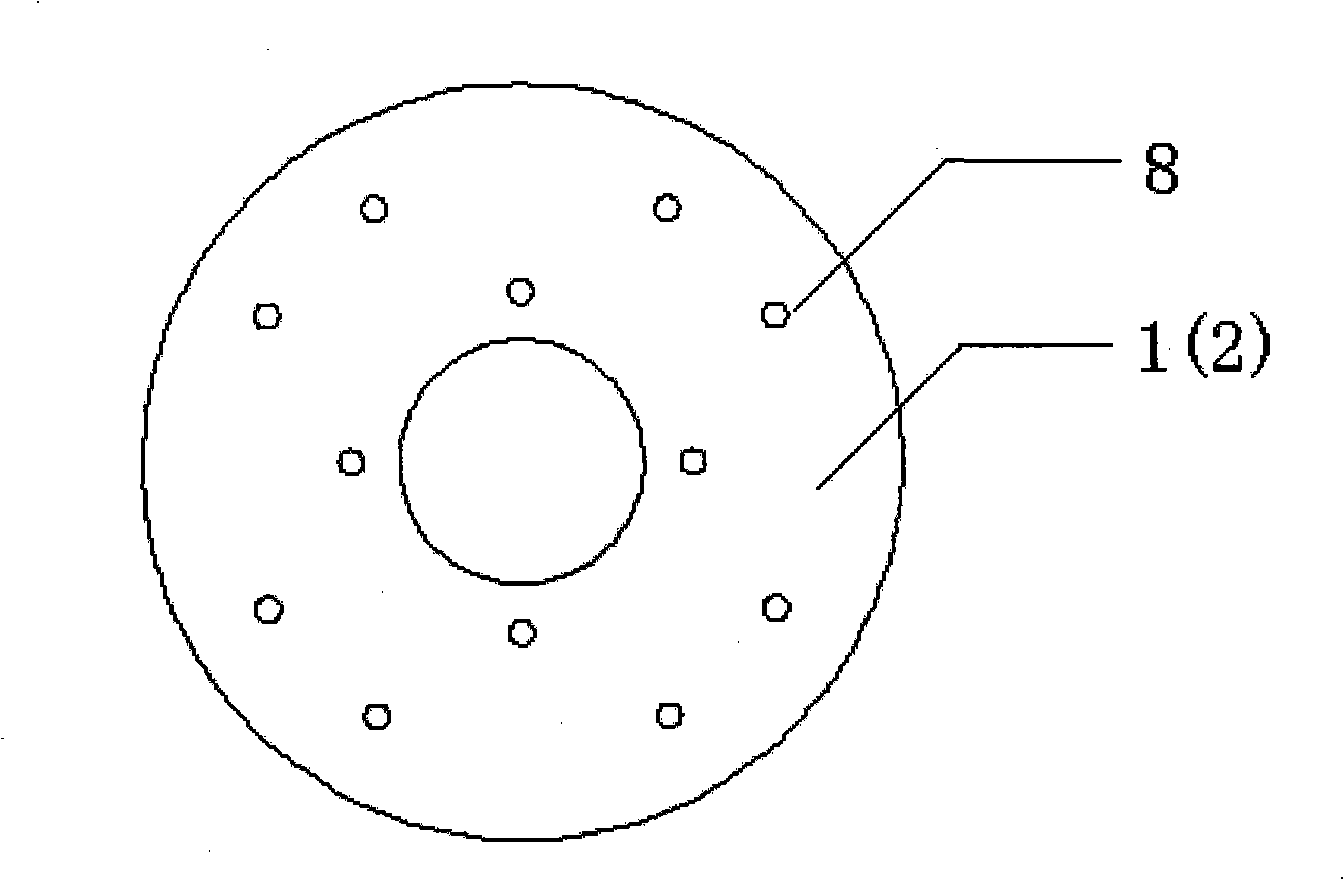

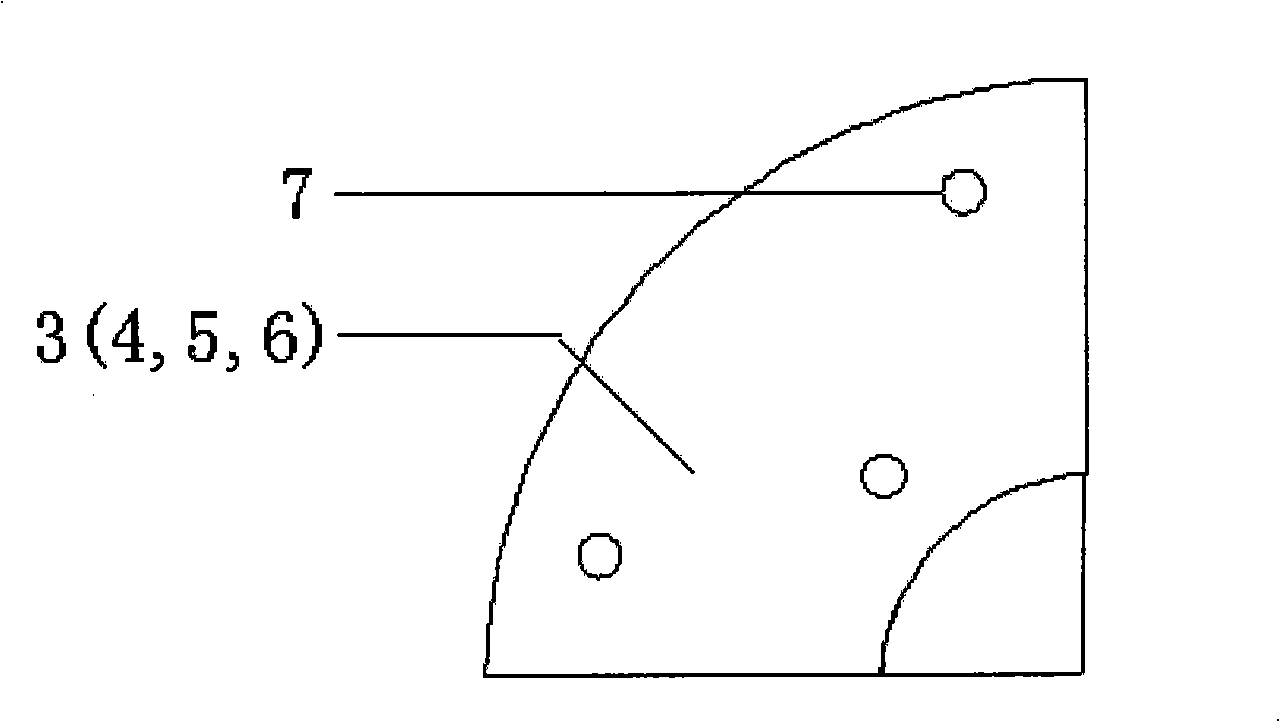

[0019] to combine figure 1 and Figure 5 The fiber optic gyroscope deskeleton fiber ring removal device consists of two discs 1 and 2 of the same specification, and four fan pages 3, 4, 5 and 6 of the same specification that can be combined into a disc. Combining both Figure 3 and Figure 4 , each leaf has a positioning step 9 and mounting holes 7 are evenly distributed on both sides. Simultaneously combine figure 2 and Figure 4 , there are mounting holes 8 corresponding to the mounting holes 7 on the fan leaf on the surface of the disc. The fan blades are four 90° fan pages. There are three mounting holes on each fan.

[0020] The optical fiber can be wound on the optical fiber winding reel according to different winding processes and packaging processes. After it is cured and glued, the fiber optic gyroscope deskeleton fiber ring disassembly device can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com