Metal plastic forming device with bidirectional extrusion function

A plastic forming and bidirectional extrusion technology, applied in the field of metal plastic forming devices, can solve the problems of excessive wear of hydraulic cylinder seals, increase in cost, increase in die loss, etc., achieve reliable operation, reduce energy supply requirements, and maintain handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

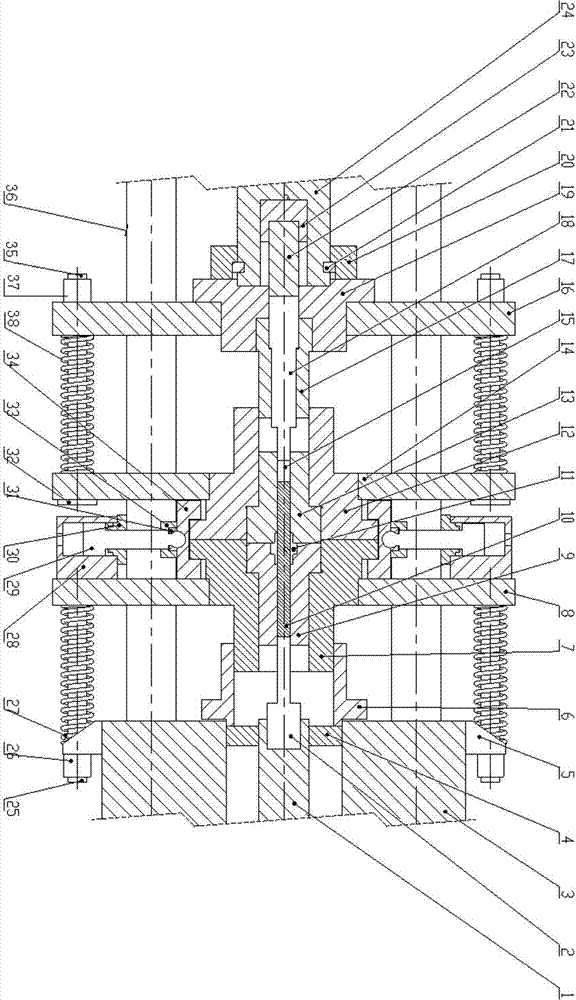

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

[0024] refer to figure 1 , this embodiment includes a master cylinder piston rod 24, an intermediate moving plate 14, an upper punch 15, a dowel 22, an upper die core 13, an upper stress ring 12, Lower stress circle 7, lower mold core 9, lower moving plate 8, lock 34, lock piston rod 29, lower girder 3, buckle barrel 6, lower punch 2, upper moving plate 16, first limit spring 27, The first limit rod 25, the second limit spring 38, the second limit rod 35;

[0025] The master cylinder piston rod 24 is fixedly connected with the upper mold base 19 through the key 21 and the key cap 20, the upper mold base 19 is connected with the upper moving plate 16 by bolts, and the upper punch 15 is connected with the upper punch base. 18 is connected by threads, and the upper punch guide sleeve 17 is arranged outside the upper punch seat 18, and the upper punch seat 18 is tightly p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com