Fiber insulation board preparation method

A thermal insulation board and fiber technology, which is applied in thermal insulation, textiles, papermaking, non-woven fabrics, etc., can solve problems such as flammability, poor safety, and aging resistance, and reduce the radiation of radioactive elements, reduce the interference of environmental noise, The effect of reducing the use of tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

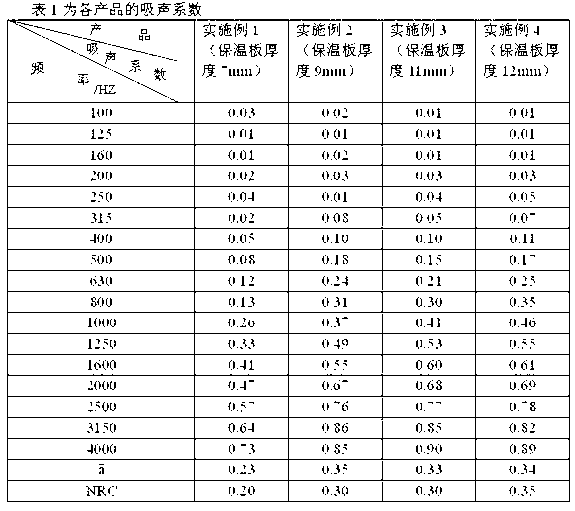

Examples

Embodiment 1

[0024] A preparation method of a fiber insulation board, comprising the steps of:

[0025] (a) Add the first polyester staple fiber and the second polyester staple fiber to the raw material feeding device, the fibers are mixed evenly through the feeding device, and the first polyester staple fiber accounts for 50% of the total fiber mass;

[0026] (b) The mixed fibers are pre-opened first to loosen the agglomerated fibers; after the pre-opening is completed, fine-opening is performed to make the fibers evenly mixed together; the opened fibers are compressed device, into the carding equipment, the fibers form a continuous fiber web after the carding equipment;

[0027] (c) Evenly spray the flame retardant of the model SAF8078 produced by Shanghai Hurt Group Co., Ltd., which accounts for 2% of the total fiber mass, onto the surface of the fiber web;

[0028] (d) The fiber web treated in step (c) is needled, rolled, and heat-set to obtain a thermal insulation board;

[0029] Th...

Embodiment 2

[0032] A preparation method of a fiber insulation board, comprising the steps of:

[0033] (a) Add the first polyester staple fiber and polyamide fiber into the raw material feeding device, the fibers are mixed evenly through the feeding device, and the first polyester staple fiber accounts for 70% of the total fiber mass;

[0034] (b) The mixed fibers are pre-opened first to loosen the agglomerated fibers; after the pre-opening is completed, fine-opening is performed to make the fibers evenly mixed together; the opened fibers are compressed device, into the carding equipment, the fibers form a continuous fiber web after the carding equipment;

[0035] (c) Evenly spray the CN-220 flame retardant produced by Changshu Yongdeli Spunlace Nonwoven Co., Ltd., which accounts for 10% of the total fiber mass, onto the surface of the fiber web;

[0036] (d) The fiber web treated in step (c) is needled, rolled, and heat-set to obtain a thermal insulation board;

[0037] The acupuncture...

Embodiment 3

[0040] A preparation method of a fiber insulation board, comprising the steps of:

[0041] (a) Add the first polyester staple fiber and carbon fiber to the raw material feeding device, the fibers are mixed evenly through the feeding device, and the first polyester staple fiber accounts for 60% of the total fiber mass;

[0042] (b) The mixed fibers are pre-opened first to loosen the agglomerated fibers; after the pre-opening is completed, fine-opening is performed to make the fibers evenly mixed together; the opened fibers are compressed device, into the carding equipment, the fibers form a continuous fiber web after the carding equipment;

[0043] (c) Evenly spray the flame retardant model Doher-6503 produced by Dongguan Sains Industrial Co., Ltd., which accounts for 6% of the total fiber mass, onto the surface of the fiber web;

[0044] (d) The fiber web treated in step (c) is needled, rolled, and heat-set to obtain a thermal insulation board;

[0045] The acupuncture densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com