Ultrasonic rolling technique

A technology of ultrasonic rolling and process method, which is applied in the field of ultrasonic rolling process, which can solve the problems that the processing range cannot meet the strength requirements, can no longer play a fixed role, and affect the processing accuracy, etc., and achieves small deformation coefficient, convenient manual adjustment, and lightening effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, in conjunction with the accompanying drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

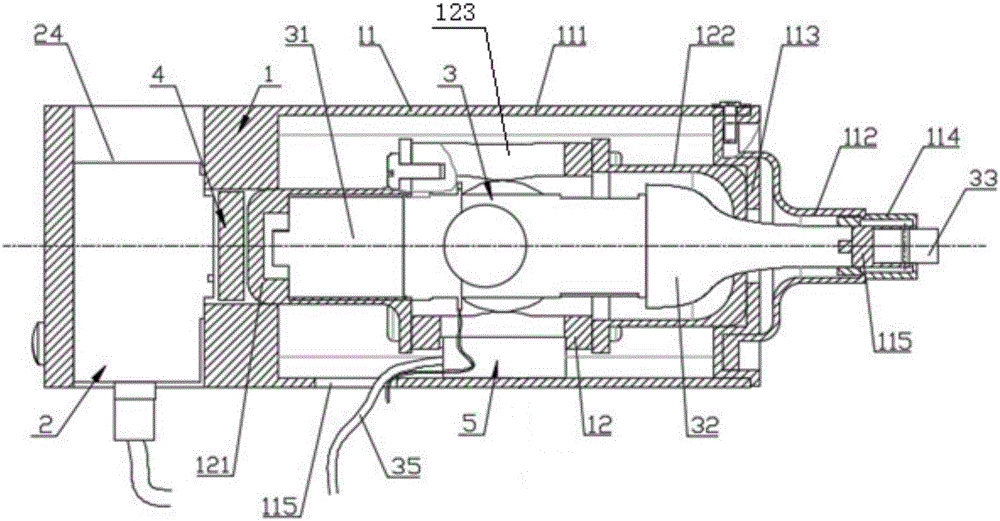

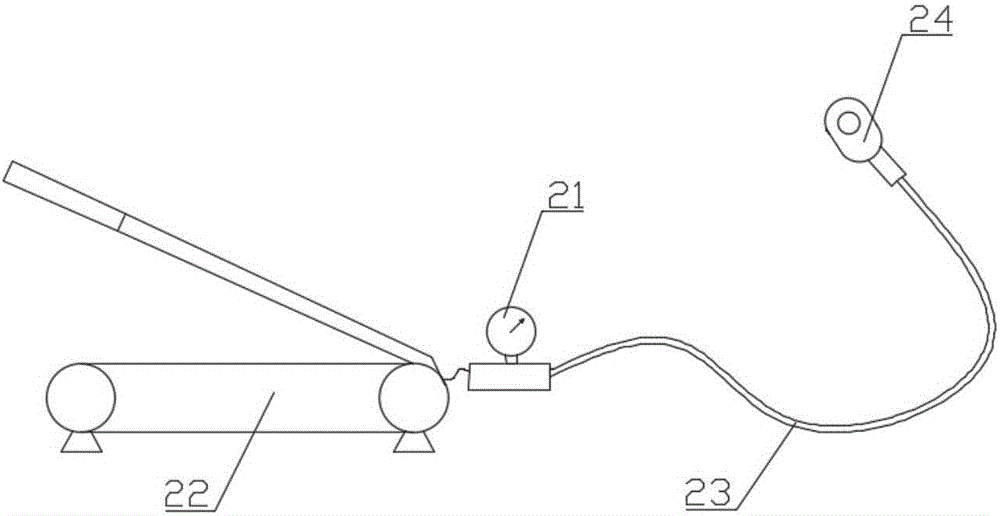

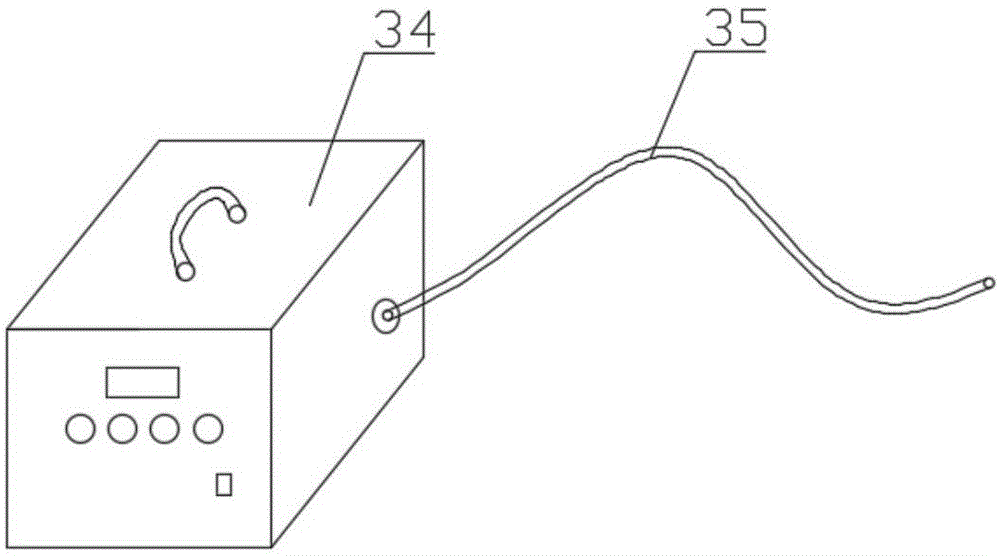

[0026] The ultrasonic rolling process method according to the present invention first includes providing an ultrasonic rolling processing device adapted to complex surfaces. see figure 1 , an ultrasonic rolling processing device adapted to complex surfaces of the present invention, comprising: a housing assembly 1, a hydraulic assembly 2 and an ultrasonic assembly 3, wherein a part of the hydraulic assembly 2 and the ultrasonic assembly 3 are fixed to the housing Component 1, and this part of the hydraulic component 2 resists the ultrasonic component 3 through the elastic body 4, and the ultrasonic component 3 is in a horizontal structure.

[0027] Specifically, the housing assembly 1 includes: an outer shell 11 and an ultrasonic fixing assembly 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com