Heat-preservation-decorating-integration plate and manufacturing method thereof

An inorganic thermal insulation board and decorative surface layer technology, applied in covering/lining, construction, building structure, etc., can solve the problems of affecting the appearance, easy to be deformed by moisture, etc., and achieve the effects of high cost, shortened construction period and small deformation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

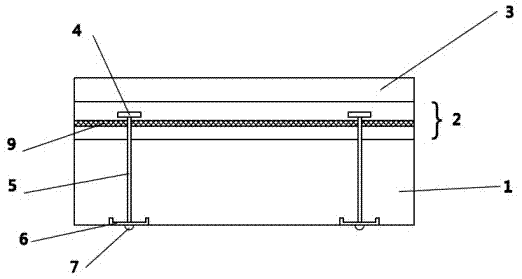

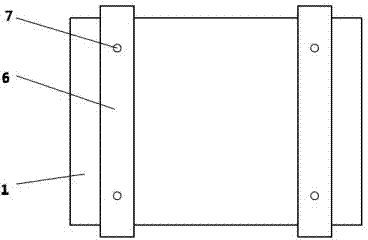

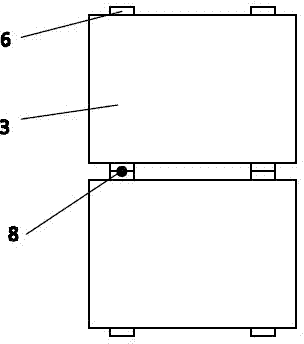

[0031] like figure 1 , figure 2 and image 3 The thermal insulation and decoration integrated board is shown, its main body is an inorganic thermal insulation board 1, the upper surface of the inorganic thermal insulation board is fixed with a lightweight aggregate concrete layer 2, and the outer surface of the lightweight aggregate concrete layer is coated with a decorative surface layer 3. A layer of wire mesh 9 is arranged in the middle of the lightweight aggregate concrete layer, and several embedded components 4 are arranged in the lightweight aggregate concrete layer, on the side adjacent to the wire mesh and the decorative surface layer, and each embedded component 4 is connected with A screw rod 5 is fixed, and the screw rod passes through the wire mesh and the inorganic heat preservation board, and is anchored with the metal keel 6 arranged at the bottom of the inorganic heat preservation board, and the screw rod and the metal keel 6 are fixed by stamping threads 7 ...

Embodiment 2

[0043] An integrated board for heat preservation and decoration, the specific structure is the same as that of Example 1, the difference is that the thickness of the lightweight aggregate concrete layer is 0.8cm, the thickness of the inorganic heat preservation board is 2cm, and the wire mesh is a wire mesh coated with anti-plating paint.

Embodiment 3

[0045] An integrated board for heat preservation and decoration, the specific structure is the same as that of Example 1, except that the thickness of the lightweight aggregate concrete layer is 1.2 cm, the thickness of the inorganic heat preservation board is 5 cm, and the wire mesh is barbed wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com