High-impact resistance and high-brightness acrylonitrile-styrene-acrylate copolymer (ASA) alloy material

An alloy material, high-brightness technology, applied in the field of high-impact, high-brightness ASA alloy material and its preparation, can solve the problems of high cost, toughness and low surface gloss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

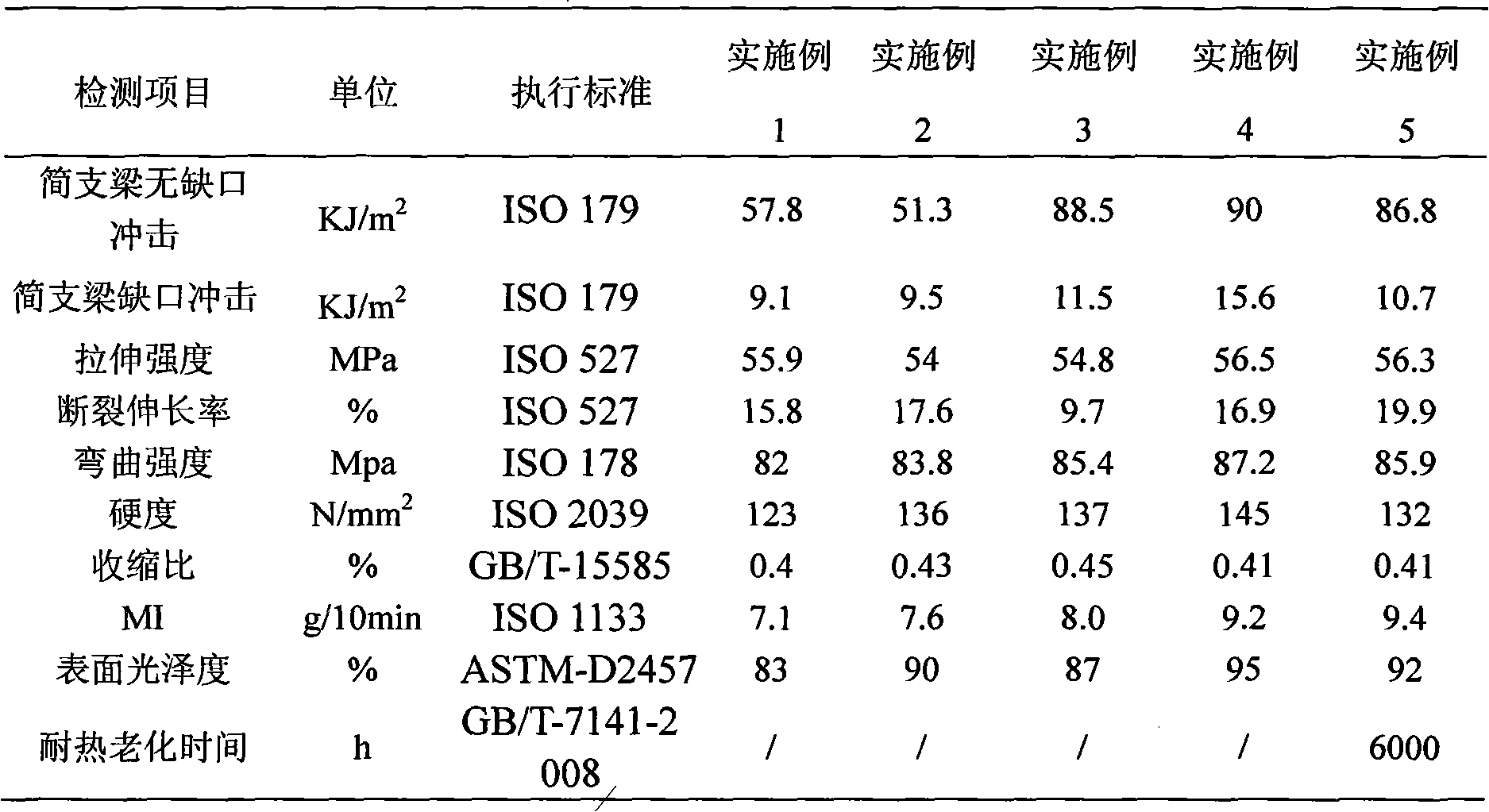

[0014] Add 70 parts of ASA resin, 10 parts of PC resin, 20 parts of PMMA resin, 0.4 part of lubricant, 0.5 part of dispersant, 0.7 part of antioxidant, 0.5 part of ultraviolet absorber into the high-speed mixer and mix for 2 to 10 minutes before discharging , the mixture is extruded and granulated through a twin-screw extruder with a diameter of 30mm, the screw speed of the extruder is 50-450r / min, and the barrel temperature is 170-250°C. The performance test results are shown in Table 1.

Embodiment 2

[0016] Add 60 parts of ASA resin, 20 parts of PC resin, 20 parts of PMMA resin, 0.4 part of lubricant, 0.5 part of dispersant, 0.7 part of antioxidant, 0.5 part of ultraviolet absorber into the high-speed mixer and mix for 2 to 10 minutes before discharging , the mixture is extruded and granulated through a twin-screw extruder with a diameter of 30mm, the screw speed of the extruder is 50-450r / min, and the barrel temperature is 170-250°C. The performance test results are shown in Table 1.

Embodiment 3

[0018] Add 70 parts of ASA resin, 20 parts of PC resin, 10 parts of PMMA resin, 0.4 part of lubricant, 0.5 part of dispersant, 0.7 part of antioxidant, 0.5 part of ultraviolet absorber into the high-speed mixer and mix for 2-10 minutes before discharging , the mixture is extruded and granulated through a twin-screw extruder with a diameter of 30mm, the screw speed of the extruder is 50-450r / min, and the barrel temperature is 170-250°C. The performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com