Anti-radiation and shock-resistant polycarbonate sheet for protective window and preparation method of polycarbonate sheet

A polycarbonate and anti-radiation technology, which is applied in the field of anti-radiation and impact-resistant polycarbonate sheets for protective windows and its preparation, can solve the problems of insufficient anti-radiation and impact resistance of polycarbonate, and improve the anti-radiation performance, Effect of improving toughness and impact resistance, strong impact resistance and radiation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A radiation-proof and impact-resistant polycarbonate sheet for protective windows, which is prepared from the following raw materials in parts by weight (kg): polycarbonate 120, graphene nanofiber 10, dialkyl cyclohexanedicarboxylate 3, Cyclic butylene terephthalate 10, tetrafluoroethylene-hexafluoropropylene copolymer 8, aluminum dihydroxystearate 5, acrylonitrile-styrene-acrylate copolymer 10, paraffin oxide 6, trimellitic acid Triisononyl ester 5, fluff powder 6, dipentaerythritol hexacarboxylate 2, lead sulfide 3, lanthanum oxalate 4, magnesium oxide whisker 6, triethylenediamine 3, nano barium carbonate 16, aramid short fiber 6, carbonization Silicon wafer 7, dibasic lead stearate 5.

[0017] A method for preparing a radiation-proof and impact-resistant polycarbonate sheet for protective windows, comprising the following steps:

[0018] (1) Dry polycarbonate and graphene nanofibers at a temperature of 110-120°C for 2-3 hours, and then add them to the high-mixing ...

Embodiment 2

[0023] A radiation-proof and impact-resistant polycarbonate sheet for protective windows, which is prepared from the following raw materials in parts by weight (kg): polycarbonate 125, graphene nanofiber 11, dialkyl cyclohexanedicarboxylate 4, Cyclic butylene terephthalate 12, tetrafluoroethylene-hexafluoropropylene copolymer 9, aluminum dihydroxystearate 6, acrylonitrile-styrene-acrylate copolymer 11, oxidized paraffin wax 7, trimellitic acid Triisononyl ester 6, fluff powder 7, dipentaerythritol hexacarboxylate 3, lead sulfide 4, lanthanum oxalate 5, magnesium oxide whisker 6.5, triethylenediamine 3.5, nano barium carbonate 18, nano zinc oxide 1, aramid fiber Short fiber 7, silicon carbide lamella 8, dibasic lead stearate 6.5.

[0024] The preparation method is the same as in Example 1.

Embodiment 3

[0026] A radiation-proof and impact-resistant polycarbonate sheet for protective windows, which is prepared from the following raw materials in parts by weight (kg): polycarbonate 130, graphene nanofiber 12, dialkyl cyclohexanedicarboxylate 5, Cyclic butylene terephthalate 14, tetrafluoroethylene-hexafluoropropylene copolymer 10, aluminum dihydroxystearate 7, acrylonitrile-styrene-acrylate copolymer 12, paraffin oxide 8, trimellitic acid Triisononyl ester 7, fluff powder 8, dipentaerythritol hexacarboxylate 4, lead sulfide 5, lanthanum oxalate 6, magnesium oxide whisker 7, triethylenediamine 4, nano barium carbonate 20, aramid short fiber 8, carbonization Silicon wafer crystal 9, silicon carbide whisker 1, carbonized rice husk 0.5, dibasic lead stearate 8.

[0027] The preparation method is the same as in Example 1.

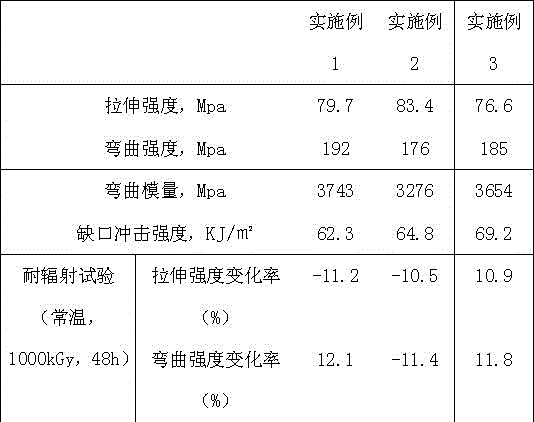

[0028] The performance testing result of the polycarbonate sheet material that above-mentioned embodiment 1-3 makes is shown in the table below:

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com