Preparation method of ASA (acrylonitrile styrene acrylate) powder

A technology of ASA resin and high rubber powder, applied in the field of preparation of ASA resin high rubber powder, can solve the problems of high rubber powder impact strength, reduced colorability and fluidity, difficult to control reaction rate, difficult to control rubber particle size, etc. Improve the effect of low tinting performance, avoid product defect problems, improve tinting and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

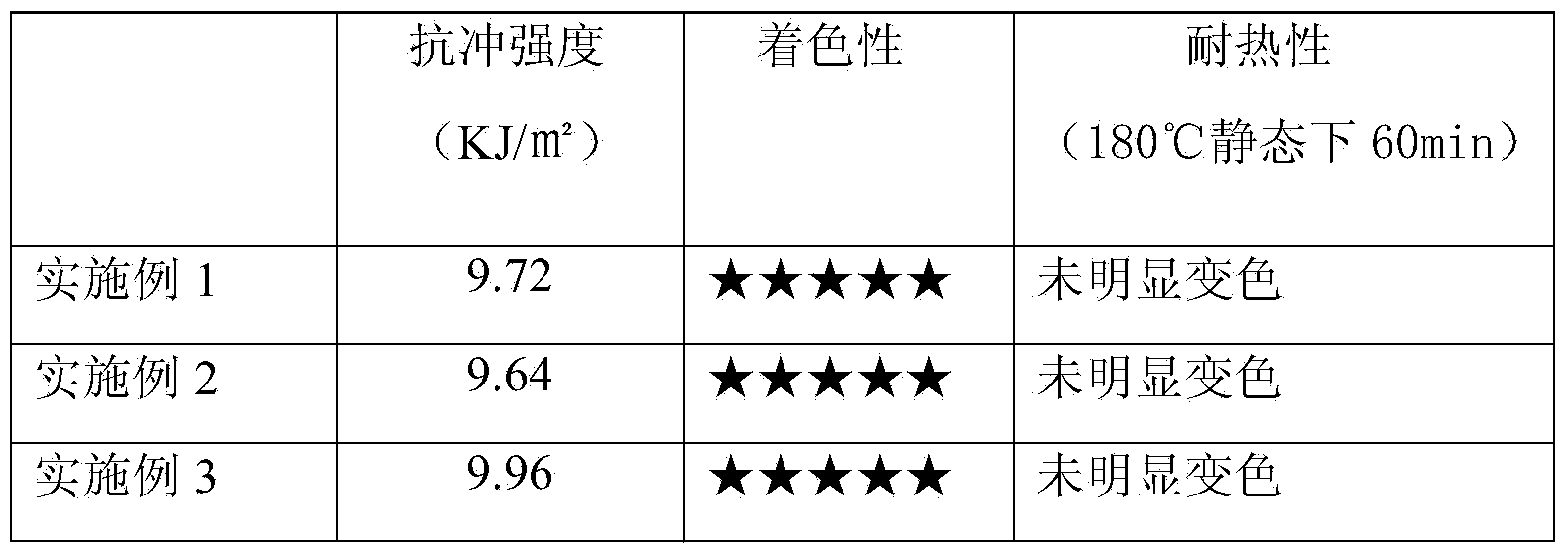

Examples

Embodiment 1

[0041] The emulsifier used in Example 1 is sodium lauryl sulfate; the initiator is potassium persulfate; the crosslinking agent is dicumyl hydroperoxide; the diameter expander is trisodium phosphate.

[0042] A preparation method for ASA resin high rubber powder, comprising the following steps:

[0043] (1) Add 150g of deionized water, 0.1g of diameter expander, 0.5g of emulsifier, 100g of butyl acrylate and 0.6g of cross-linking agent into the reaction vessel, raise the temperature to 65°C, add 0.1g of initiator, under nitrogen protection React for 5 hours to obtain acrylate seed latex;

[0044](2) Add 150g deionized water, 0.1g diameter expander, 0.5g emulsifier, 100g butyl acrylate and 0.6g crosslinking agent in 20g of acrylate seed latex (solid amount) obtained in step (1), control Warm to 70°C, add 0.1g initiator and react for 5 hours under nitrogen protection to obtain the core layer latex;

[0045] (3) add 20g into the mixture of styrene and acrylonitrile in the core ...

Embodiment 2

[0050] The emulsifier used in Example 2 is sodium dodecylsulfonate; the initiator AIBN and BPO are mixed at a mass ratio of 1:1; the crosslinking agent is dicumyl hydroperoxide; the diameter expander is sodium sulfate.

[0051] A preparation method for ASA resin high rubber powder, comprising the following steps:

[0052] (1) Add 200g of deionized water, 0.4g of diameter expander, 2g of emulsifier, 100g of ethyl acrylate and 1g of crosslinking agent into the reaction vessel, raise the temperature to 70°C, add 0.3g of initiator, and react under nitrogen protection for 5 Hour, obtain acrylate seed latex;

[0053] (2) Add 150g deionized water, 0.5g diameter expander, 1.8g emulsifier, 95g butyl acrylate and 1.8g crosslinking agent to the acrylate seed latex obtained in step (1) (solid content is 35g), Raise the temperature to 72°C, add 0.4g initiator, and react for 4.5 hours under the protection of nitrogen to obtain the core layer latex;

[0054] (3) Add the mixture of 21g styr...

Embodiment 3

[0058] The emulsifier used in Example 3 is sodium dodecylbenzenesulfonate; the initiator is ammonium persulfate; the crosslinking agent is allyl methacrylate; the diameter expander is sodium chloride.

[0059] A preparation method for ASA resin high rubber powder, comprising the following steps:

[0060] (1) Add 200g of deionized water, 0.4g of diameter expander, 1g of emulsifier, 100g of isooctyl acrylate and 1.8g of crosslinking agent into the reaction vessel, raise the temperature to 75°C, add 0.5g of initiator, under nitrogen protection React for 4 hours to obtain acrylate seed latex;

[0061] (2) Add 200g deionized water, 0.3g diameter expander, 1.0g emulsifier, 128g butyl acrylate and 1.0g crosslinking agent to the acrylate seed latex (12g of solid content) obtained in step (1), control Warm to 70°C, add 0.5g initiator, react under nitrogen protection for 5 hours to obtain the core layer latex;

[0062] (3) Add the mixture of 20g styrene and acrylonitrile to the core l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com