Colored PVC decoration sectional material and production method thereof

A decorative profile and PVC resin technology, which is applied in the field of color PVC decorative profiles and their production, can solve the problems of unsatisfactory surface quality, ultraviolet light resistance, scratch resistance and other practical effects of the color PVC profiles, so as to increase the decorative effect and improve the additional value, the effect of improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1, a kind of colored PVC decorative profile, consists of the following components by weight: 100 parts of PVC resin, 4 to 5 parts of stabilizer, 4.5 to 5 parts of titanium dioxide, 1.5 to 2 parts of ACR, calcium carbonate 22 to 26 parts, CPE 6.5 to 7.5 parts, ultramarine 0.042 to 1.145 parts, whitening agent 0.008 to 0.010 parts, paraffin wax 0.5 to 0.6 parts, PE wax 0.4 to 0.5 parts, ASA / PMMA resin 2 parts to 2.5 parts, microemulsion 1.5 to 2 parts.

[0014] According to actual needs, the above-mentioned one of the colored PVC decorative profiles can be further optimized or / and improved:

[0015] The microemulsion is obtained by fully mixing a commercially available weather-resistant self-cleaning emulsion and luminescent material particles, and the mixing ratio is 0.5 to 0.8 parts of luminescent material particles per 100 parts of weather-resistant self-cleaning emulsion. Luminescent materials are made of various inorganic oxides fired at high temper...

Embodiment 2

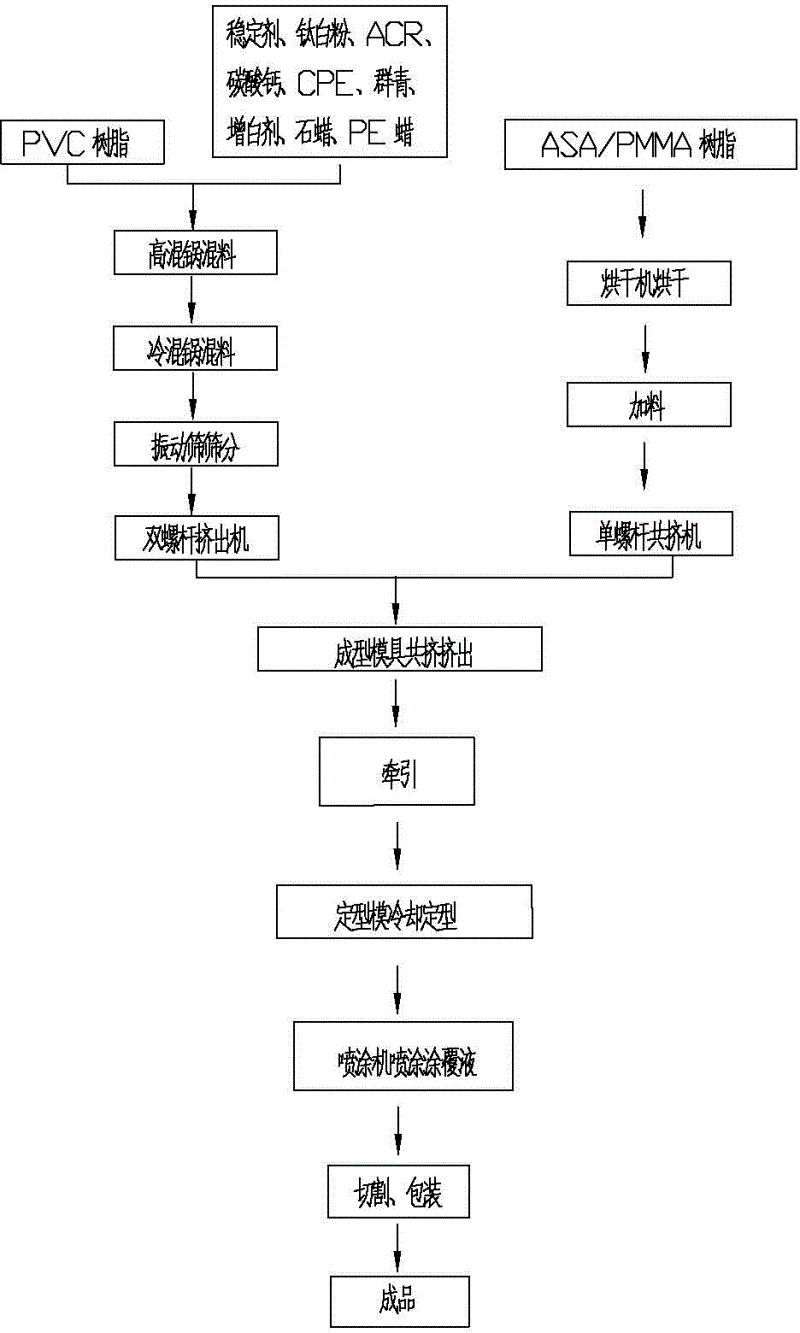

[0018] Embodiment 2, a kind of production method of colored PVC decorative profile, carries out according to the following steps:

[0019] The first step, preparation of dry mixed powder: accurately weigh PVC resin, stabilizer, titanium dioxide, ACR, calcium carbonate, CPE, ultramarine blue, whitening agent, paraffin wax and PE wax according to the formula, and put the weighed PVC resin , stabilizer, titanium dioxide, ACR, calcium carbonate, CPE, ultramarine blue, whitening agent, paraffin wax and PE wax are put into the high mixing pot to start mixing, when the dry mixing temperature in the high mixing pot reaches 115°C to 125°C Start discharging to the cold mixing pot and start cooling. When the temperature of the dry mix drops to between 10°C and 50°C, discharge the dry mix in the cold mixing pot to a vibrating screen for screening and discharging, and prepare Produce loose and easy-flowing dry-mixed powder, and send the dry-mixed powder to the storage bin for standby; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com