Ultralow-glossiness ultralow-temperature-resistant ASA resin composition and preparation method thereof

A technology of ASA resin and low temperature resistance, applied in the field of polymer materials, it can solve the problem of reducing impact strength, tensile strength, flexural strength, flexural modulus and mechanical properties, reducing the impact performance of ASA resin at room temperature and low temperature, and reducing the gloss of ASA resin, etc. problems, to achieve the effect of improving compatibility, improving surface gloss, and reducing surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

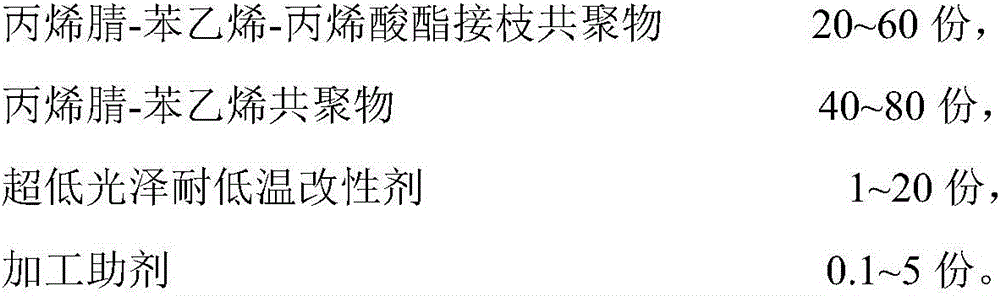

Method used

Image

Examples

Embodiment 1

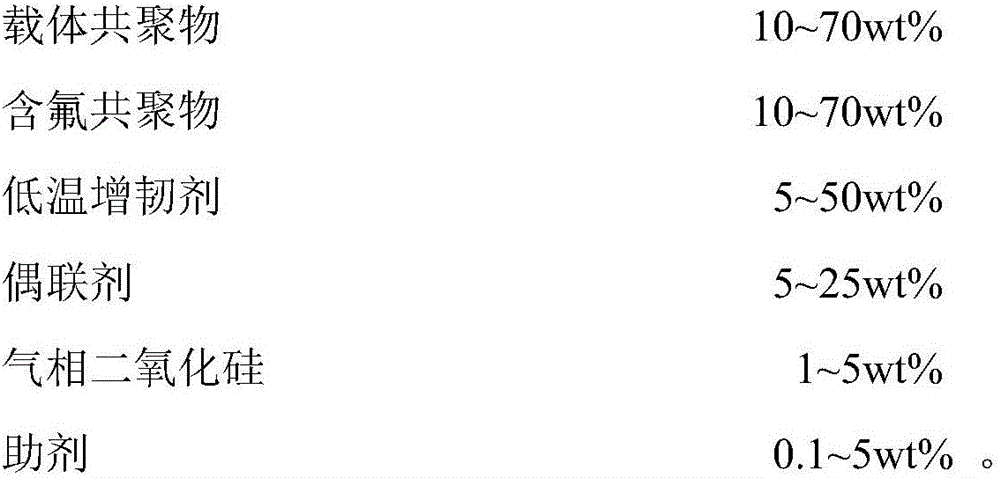

[0045] Embodiment 1 Preparation of Ultra-Low Gloss Low Temperature Modifier

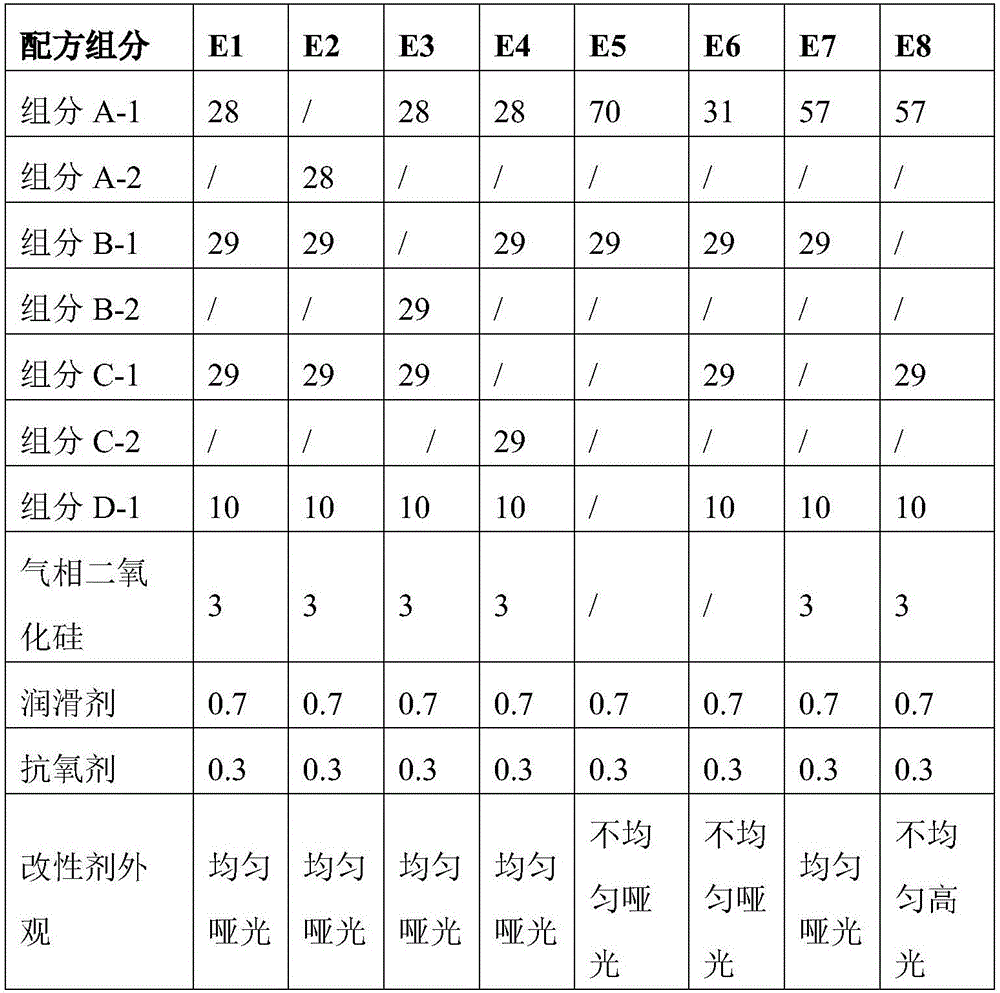

[0046] Table 1 shows the components and weight percentages of the ultra-low gloss low temperature resistant modifier (E). Carrier copolymer (A), fluorine-containing copolymer (B), low temperature toughening agent (C), coupling agent (D), fumed silica, lubricant EBS 0.7phr and antioxidant IG-1076 0.3phr Stir and mix in the high-speed mixer, enter the twin-screw extruder through the metering device, and under the conveying, shearing and mixing of the screw, the material is melted and compounded, and then extruded, drawn, cooled and pelletized steps to obtain ultra-low gloss and low-temperature resistant modifiers E1 to E8 with uniform particle size.

[0047] Wherein, the screw aspect ratio of the twin-screw extruder is 40; the extrusion temperature of the twin-screw extruder is between 200-300° C., and the screw speed is 200-500 rpm.

[0048] Table 1 Preparation of ultra-low gloss low temperature re...

Embodiment 2~9

[0059] Embodiment 2~9 preparation of ultra-low gloss, ultra-low temperature resistant ASA resin composition

[0060] Examples 2 to 9 provide an ultra-low gloss, ultra-low temperature resistant ASA resin composition and its preparation method. The components and weight percentages in the ultra-low gloss, ultra-low temperature resistant ASA resin composition are shown in the table 2, the preparation method is: acrylonitrile-styrene-acrylate graft copolymer, acrylonitrile-styrene copolymer and ultra-low gloss low temperature resistance modifier (E), lubricant EBS 0.6phr and antioxidant The agent IG-1076 0.3phr is stirred and mixed in the high-speed mixer, and enters the twin-screw extruder through the metering device. Under the conveying, shearing and mixing of the screws, the materials are melted and compounded, and then extruded Stripping, cooling, and pelletizing steps to obtain an ASA resin composition with ultra-low gloss and ultra-low temperature resistance.

[0061] Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average particle size | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com