High-heat resistance and low-gloss antistatic PC/ASA alloy material and preparation method thereof

An alloy material, low gloss technology, applied in the field of alloy materials, can solve the problems of easy friction electrification, electrostatic dust collection, spark discharge, etc., and achieve the effect of excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6 and comparative example 1

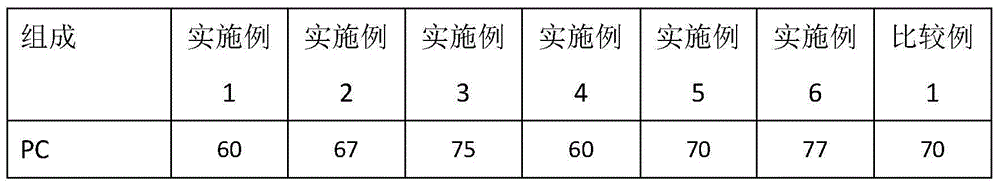

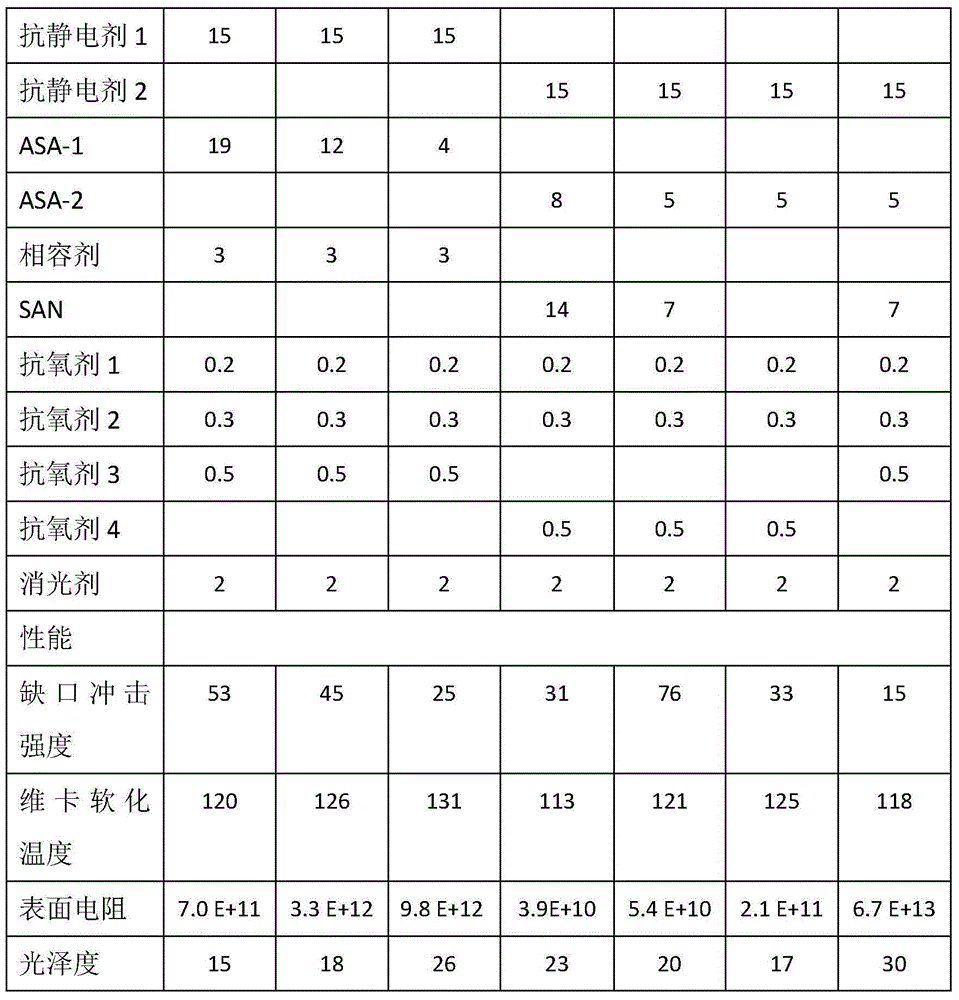

[0036] Mix the dried PC resin, antistatic agent, ASA, SAN and compatibilizer etc. according to the composition ratio in Table 1, and then use a twin-screw feeder to continuously and evenly add the twin-screw extruder (screw diameter 35mm, length-to-diameter ratio L / D=36) In the main cylinder, the temperature of the main cylinder is controlled in sections (from the feeding port to the nozzle outlet) to 170°C, 200°C, 220°C, 230°C, 230°C, 235°C, 225°C, and the twin-screw speed is 300 rpm / minute, the extruded strips are cooled in a water tank and then pelletized to obtain the product. Above-mentioned product is injection molded into standard spline with plastic injection molding machine after being dried at 85 ℃ for 4 hours in blast oven, and injection molding temperature is 230 ℃. The injection-molded strips were immediately placed in a glass desiccator at room temperature for at least 24 hours before performance testing. The test results are shown in Table 1.

[0037] Compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com