Method for preparing ASA (Acrylonitrile-Styrene-Acrylate) copolymer latex by using water-solubility redox initiator at low temperature

A technology of copolymer latex and initiator, which is applied in the field of preparing ASA copolymer latex, can solve the problems of poor repeatability and difficult control, and achieve the effects of good repeatability, easy operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

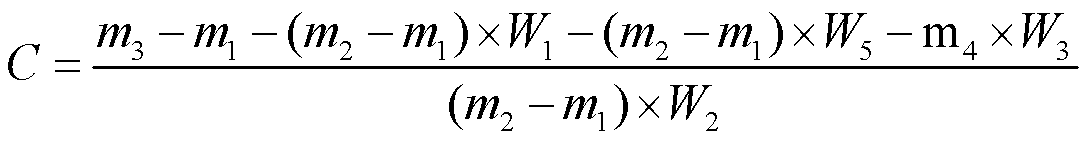

Image

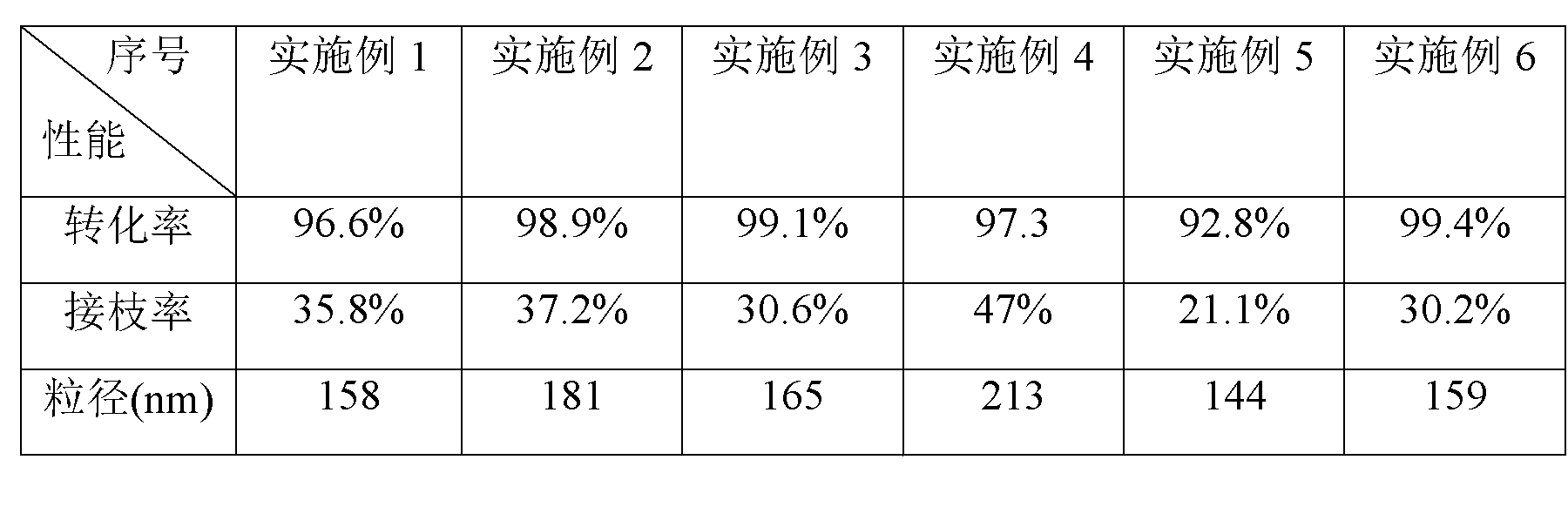

Examples

Embodiment 1

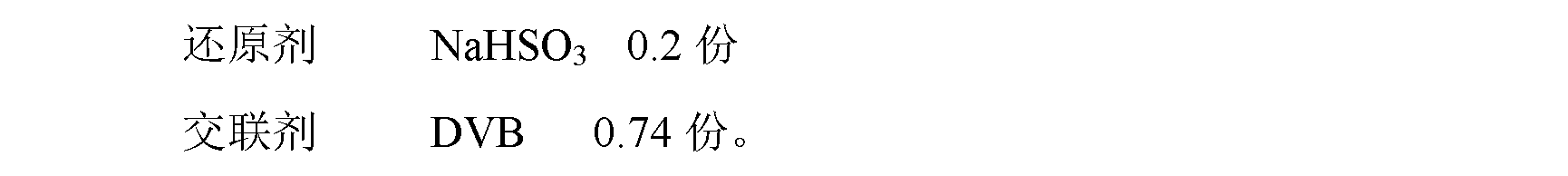

[0060] Each raw material constitutes by mass parts:

[0061]

[0062]

[0063] The preparation method is as follows:

[0064] 1) Add 0.088 parts of SDS to deionized water under the protection of nitrogen, and add 3.7 parts of BA after dispersing evenly. After stirring evenly, add 0.054 parts of KPS aqueous solution and 0.04 parts of NaHSO dropwise at the same time. 3 The aqueous solution, dripped within ten minutes, reacted at 60°C for 2h;

[0065] 2) Add 0.054 parts of KPS aqueous solution dropwise to the reaction solution in step 1), and then add the core layer monomer pre-emulsion dropwise to the reaction solution, and react at 60°C for 3 hours;

[0066] The core monomer pre-emulsion is composed of 7.4 parts of BA, 4.4 parts of St, 2.2 parts of AN, 0.74 parts of HDDA, 0.132 parts of SDS, 0.04 parts of NaHSO 3 Stir and emulsify with deionized water to obtain;

[0067] 3) Add 0.162 parts of KPS aqueous solution dropwise to the reaction solution in step 2), then add t...

Embodiment 2

[0070] Embodiment 2: comparative example—thermal decomposition initiates

[0071] Each raw material constitutes by mass parts:

[0072]

[0073] The preparation method is as follows:

[0074] 1) Add 0.088 parts of SDS into deionized water under the protection of nitrogen, disperse evenly, add 3.7 parts of BA, stir evenly, add 0.054 parts of KPS aqueous solution dropwise, finish dropping within ten minutes, and react at 75°C for 2 hours;

[0075] 2) Add 0.054 parts of KPS aqueous solution dropwise to the reaction solution in step 1), and then add the core layer monomer pre-emulsion dropwise to the reaction solution, and react at 75°C for 3 hours;

[0076] The core layer monomer pre-emulsion is obtained by stirring and emulsifying 7.4 parts of BA, 4.4 parts of St, 2.2 parts of AN, 0.74 parts of HDDA, 0.132 parts of SDS and deionized water;

[0077] 3) Add 0.162 parts of KPS aqueous solution dropwise to the reaction solution in step 2), then add the shell monomer pre-emulsio...

Embodiment 3

[0081] Each raw material constitutes by mass parts:

[0082]

[0083] The preparation method is as follows:

[0084] 1) Add 0.088 parts of SDS to deionized water under the protection of nitrogen, and add 3.7 parts of BA after dispersing evenly. After stirring evenly, add 0.054 parts of KPS aqueous solution and 0.04 parts of NaHSO dropwise at the same time. 3 The aqueous solution, dripped within ten minutes, reacted at 60°C for 2h;

[0085] 2) Add 0.054 parts of KPS aqueous solution dropwise to the reaction solution in step 1), and then add the core layer monomer pre-emulsion dropwise to the reaction solution, and react at 60°C for 3 hours;

[0086] The core monomer pre-emulsion is composed of 7.4 parts of BA, 4.4 parts of St, 2.2 parts of AN, 0.132 parts of SDS, 0.04 parts of NaHSO 3 Stir and emulsify with deionized water to obtain;

[0087] 3) Add 0.162 parts of KPS aqueous solution dropwise to the reaction solution in step 2), and then add the shell monomer pre-emulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com