Antistatic ultraviolet-resistant ASA/PET alloy material and preparation method thereof

A technology of anti-ultraviolet and alloy materials, which is applied in the field of alloy materials to achieve the effects of cost reduction, excellent mechanical properties and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

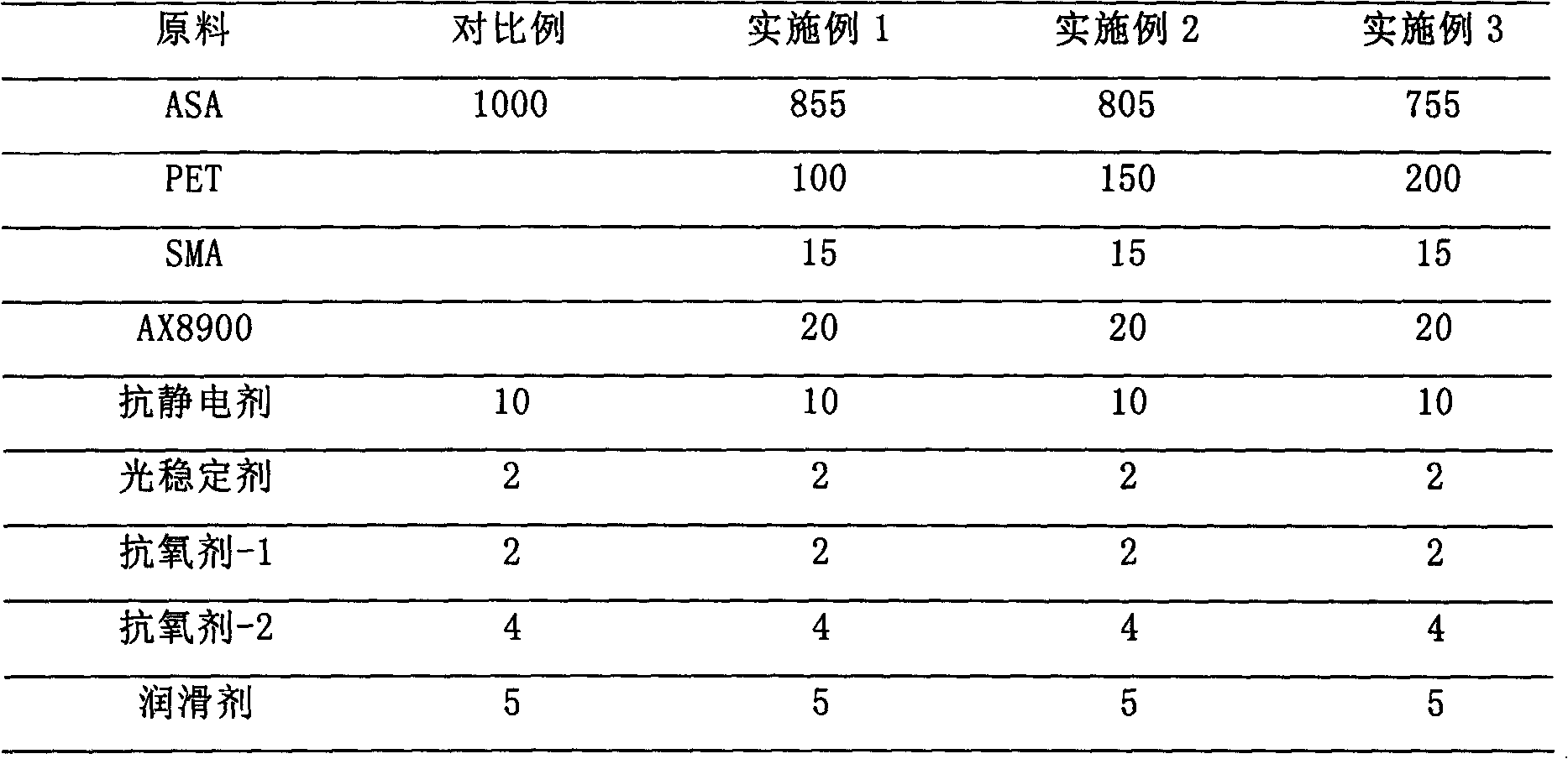

Embodiment 1

[0051] (1) Prepare materials according to the following ratio: Acrylonitrile-styrene-acrylate copolymer (ASA) 855kg, polyethylene terephthalate (PET) 100kg, styrene-grafted maleic anhydride copolymer (SMA) 15kg, ethylene-acrylate copolymer (AX8900) 20kg, antistatic agent 10kg, lubricant 0.3kg, light stabilizer 5kg, antioxidant-1 (1010) 2kg, antioxidant-2 (168) 4kg.

[0052] (2) After the above raw materials are prepared in proportion and pre-mixed, they are extruded through a twin-screw extruder at 220-250°C, discharged in the form of strands, and then granulated by a granulator to obtain the product.

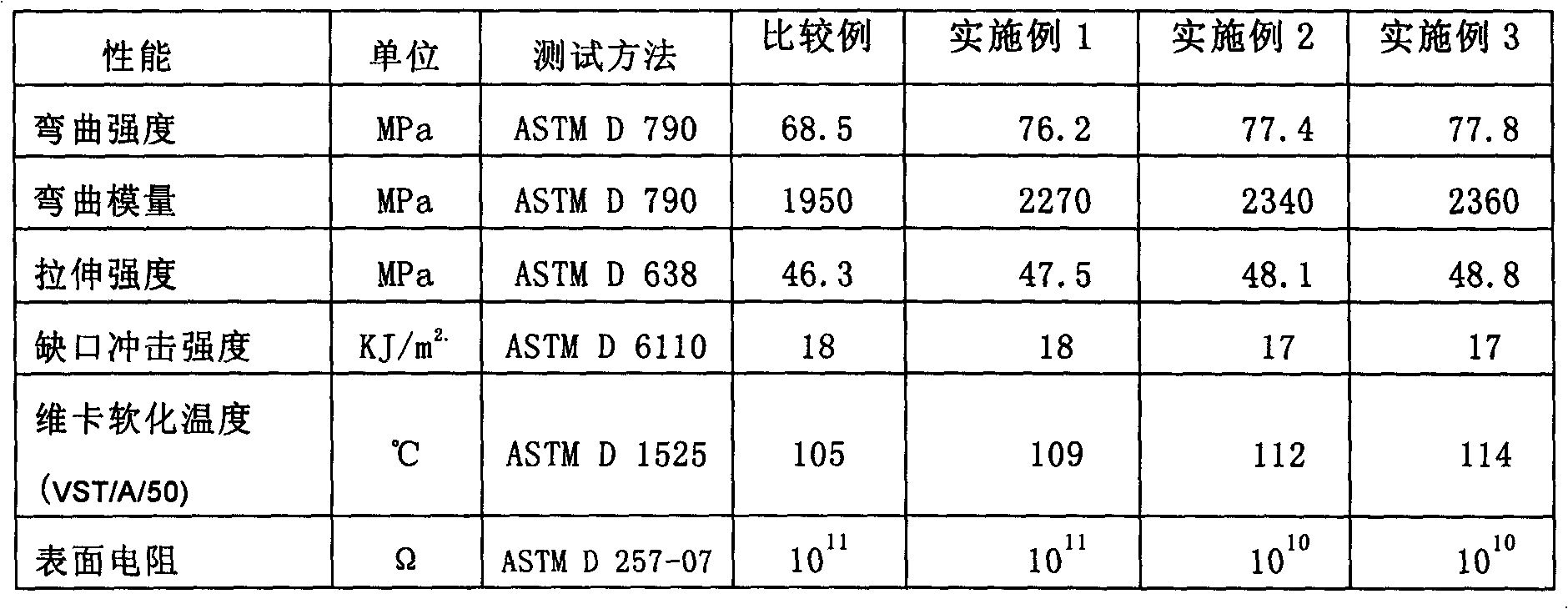

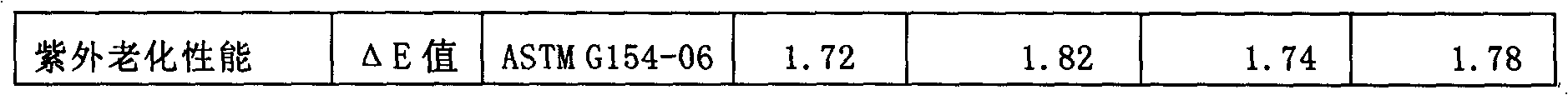

[0053] See Table 2 for the performance test results of the product obtained in Example 1.

Embodiment 2

[0055] (1) Prepare materials according to the following ratio: Acrylonitrile-styrene-acrylate copolymer (ASA) 805kg, polyethylene terephthalate (PET) 150kg, styrene grafted maleic anhydride copolymer (SMA) 15kg, ethylene-acrylate copolymer (AX8900) 20kg, antistatic agent 10kg, lubricant 0.3kg, light stabilizer 5kg, antioxidant-1 (1010) 2kg, antioxidant-2 (168) 4kg.

[0056] (2) After the above raw materials are prepared in proportion and pre-mixed, they are extruded through a twin-screw extruder at 220-250°C, discharged in the form of strands, and then granulated by a granulator to obtain the product.

[0057] See Table 2 for the product performance test result of embodiment 2 gained.

Embodiment 3

[0059](1) Prepare materials according to the following ratio: acrylonitrile-styrene-acrylate copolymer (ASA) 755kg, polyethylene terephthalate (PET) 200kg, styrene-grafted maleic anhydride copolymer (SMA) 15kg, ethylene-acrylate copolymer (AX8900) 20kg, antistatic agent 10kg, lubricant 0.3kg, light stabilizer 5kg, antioxidant-1 (1010) 2kg, antioxidant-2 (168) 4kg.

[0060] (2) After the above raw materials are prepared in proportion and pre-mixed, they are extruded through a twin-screw extruder at 220-250°C, discharged in the form of strands, and then granulated by a granulator to obtain the product.

[0061] See Table 2 for the product performance test result of embodiment 3 gained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com