Stable permeation composite type rust coating and preparation method thereof

A kind of rusted paint, composite technology, applied in anti-corrosion paint, epoxy resin paint, coating and other directions, can solve the problem of poor rust removal effect, and achieve the effect of small coating performance, high hardness and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

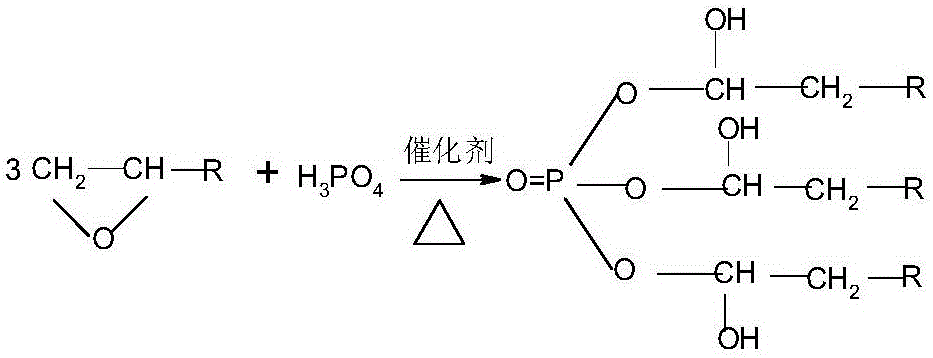

Method used

Image

Examples

Embodiment 1

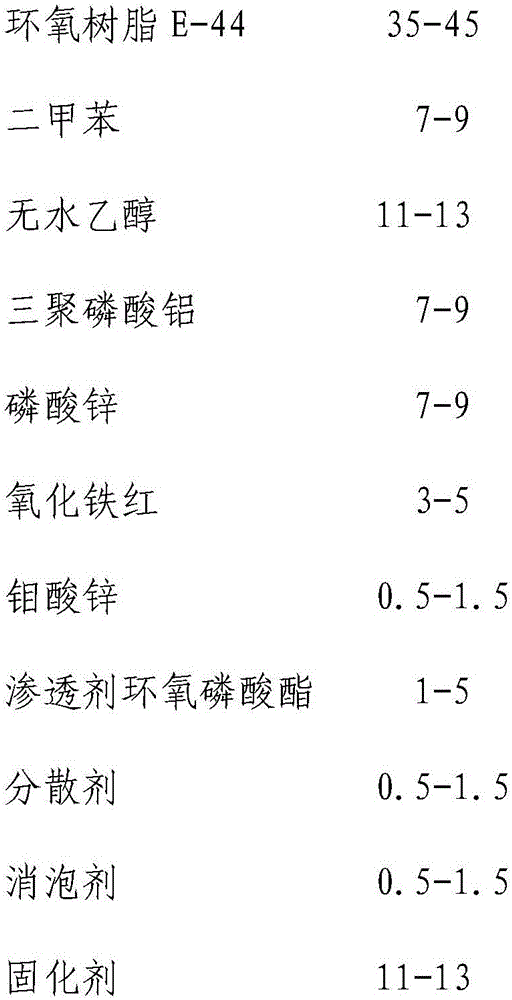

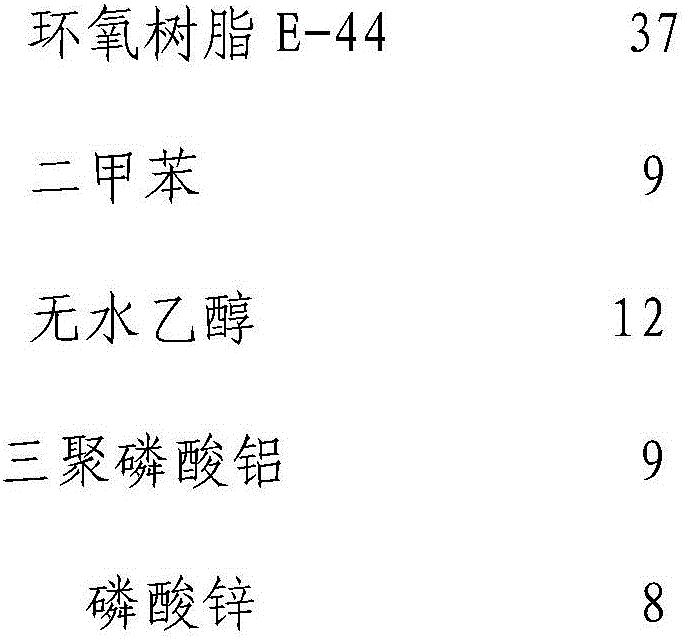

[0037] Each component quality is in the embodiment one:

[0038]

[0039]

[0040] The preparation method is:

[0041] (1) Put epoxy resin E-44 into a container, put it into a water bath and raise the temperature to about 50°C.

[0042] (2) Take out the container and add xylene and use a glass rod for preliminary stirring. After stirring evenly, add absolute ethanol, also use a glass rod for preliminary stirring, and cool to room temperature.

[0043] (3) Weigh aluminum tripolyphosphate and put it into the container after grinding, and use a glass rod for preliminary stirring until the stirring is uniform.

[0044] (4) Weigh the zinc phosphate and grind it into the container, and use a glass rod for preliminary stirring until it is evenly stirred.

[0045] (5) Add iron oxide red to the container after weighing and grinding, and stir evenly with a glass rod.

[0046] (6) Weigh the zinc molybdate and add it into the container, and stir evenly with a glass rod.

[0047]...

Embodiment 2

[0053]

Embodiment 3

[0055]

[0056]

[0057] See Example 1 for the preparation methods of Example 3 and Example 2, and will not repeat them here. The performance parameters of the final prepared coating are: the hardness of the paint film is expressed as 3H in pencil hardness, the adhesion level is 0, and the impact strength According to the GB / T1732-1993 standard test, the drop height of the weight is 50CM, and the paint film has no cracks, wrinkles and peeling off. The salt water resistance test is soaked in 5% NaCl solution for 48 hours at room temperature without foaming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com