High-pigment-content pure oil non-emulsification cosmetic color paste and preparation method

A cosmetic, non-emulsifying technology, applied in the direction of cosmetic preparations, cosmetics, cosmetics, etc., can solve the problems of affecting application and low pigment content, and achieve the effect of strong coloring ability, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] This example also provides a corresponding preparation method for the cosmetic pure oily color paste with high pigment content composed of the above-mentioned components according to the corresponding ratio. The preparation method comprises the steps of:

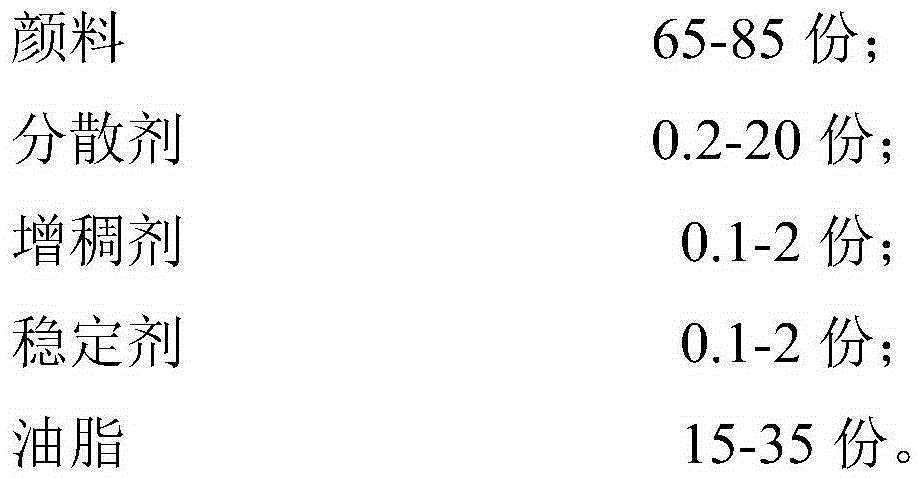

[0049] (1) Take each component according to the following parts by weight:

[0050]

[0051] Mix oil, dispersant, thickener, and stabilizer, heat and stir to obtain a uniform oily dispersion medium; the heating temperature here is 80-85°C.

[0052] (2) While heating and stirring the oily dispersion medium obtained in step (1), add 65-85 parts of pigment to disperse and mix into a slurry; the heating temperature here is 80-85°C.

[0053] (3) Disperse the slurry obtained in step (2) for 3-4 times by grinding and dispersing equipment to obtain the desired cosmetic oily color paste with high pigment content. The grinding and dispersing equipment here is at least one of a ball mill, a colloid mill, and a high-speed sh...

Embodiment 1

[0058] The formula (by weight percentage) of pure oily color paste of high pigment content cosmetics in the present example is as follows:

[0059] Iron Oxide Red

80%

Isopropyl myristate

18%

PEG-30 dipolyhydroxystearate

0.9%

0.65%

80# microcrystalline wax

0.45%

[0060] The preparation process of high pigment content cosmetic pure oily color paste in the present embodiment is as follows:

[0061] (1) Weigh the required isopropyl myristate, PEG-30 dipolyhydroxystearate, fumed silica, and 80# microcrystalline wax in proportion, mix them, heat and stir at 85°C, and obtain a uniform Oily medium for dispersion.

[0062] (2) While heating and stirring the obtained oily medium at 80° C., gradually add iron oxide red into the oily medium, and stir to form a paste-like slurry.

[0063] (3) Disperse and grind the obtained paste slurry with a colloid mill for 3-4 times to obtain a corresponding cosmetic oily c...

Embodiment 2

[0066] The formula (by weight percentage) of the high pigment content cosmetics pure oily color paste of this example is as follows:

[0067] iron oxide black

80%

Isopropyl myristate

16.3%

PEG-30 dipolyhydroxystearate

2.2%

0.7%

80# microcrystalline wax

0.8%

[0068] The preparation method of high pigment content cosmetic pure oil color paste in the present embodiment is as follows:

[0069] (1) Weigh the required isopropyl myristate, PEG-30 dipolyhydroxystearate, fumed silica, and 80# microcrystalline wax in proportion, mix them, heat and stir at 85°C, and obtain a uniform Oily medium for dispersion.

[0070] (2) The obtained oily medium was heated and stirred at 80° C., and the iron oxide black was gradually added into the oily medium, and stirred to form a paste-like slurry.

[0071] (3) Disperse and grind the obtained paste-like slurry with a sand mill for 3-4 times to obtain a corresponding cosm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com