Low-temperature-resistant, damp-heat-resistant and flame-retardant PC (polycarbonate) material for charging gun casing and preparation method of PC material

A technology of low temperature resistance and charging gun, which is applied in the field of low temperature and heat resistant and flame retardant PC materials for charging gun shells and its preparation, which can solve the problem of not considering the influence of flame retardants on the damp and heat aging performance, poor resistance to heat and humidity, and resistance to heat and humidity Poor and other problems, to achieve good photoaging ability, strong coloring ability, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7 and comparative example 1-5

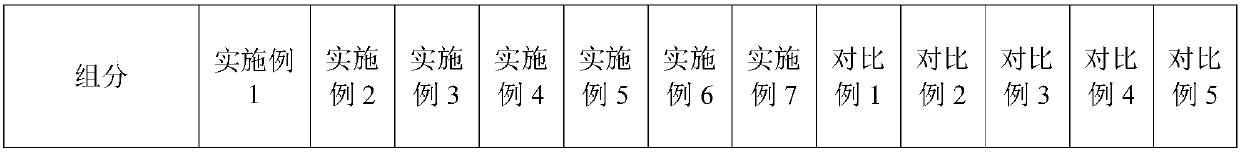

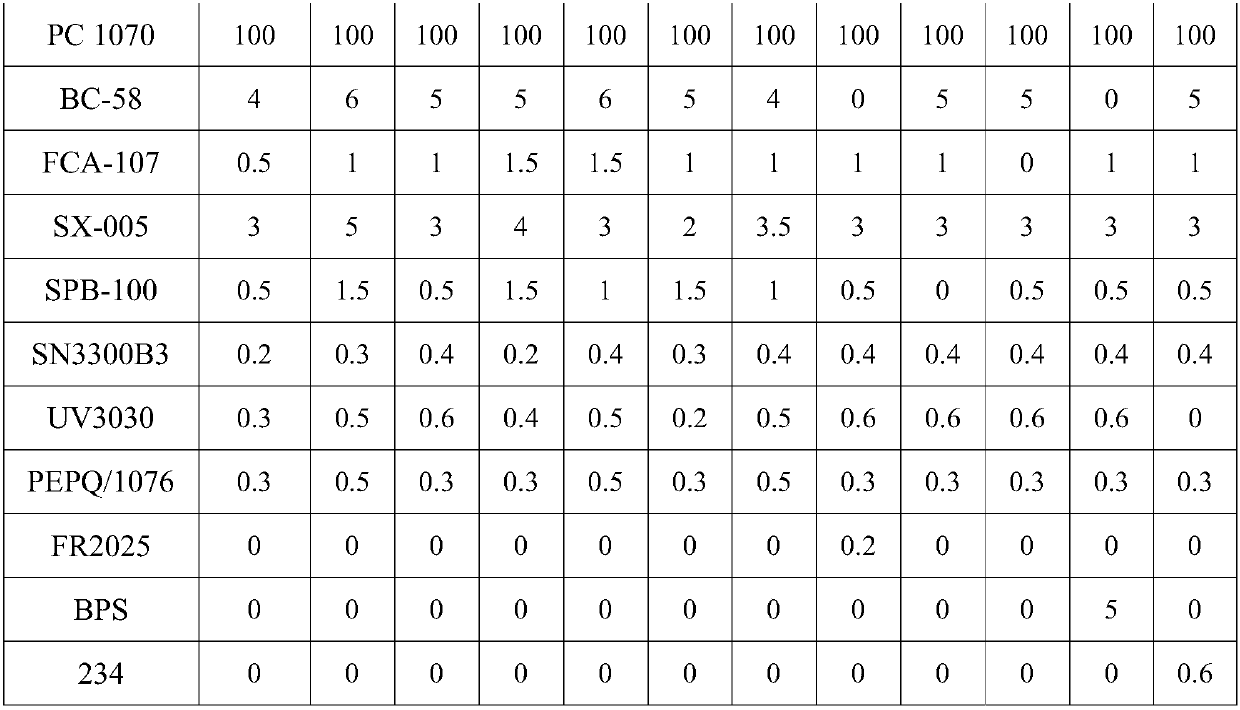

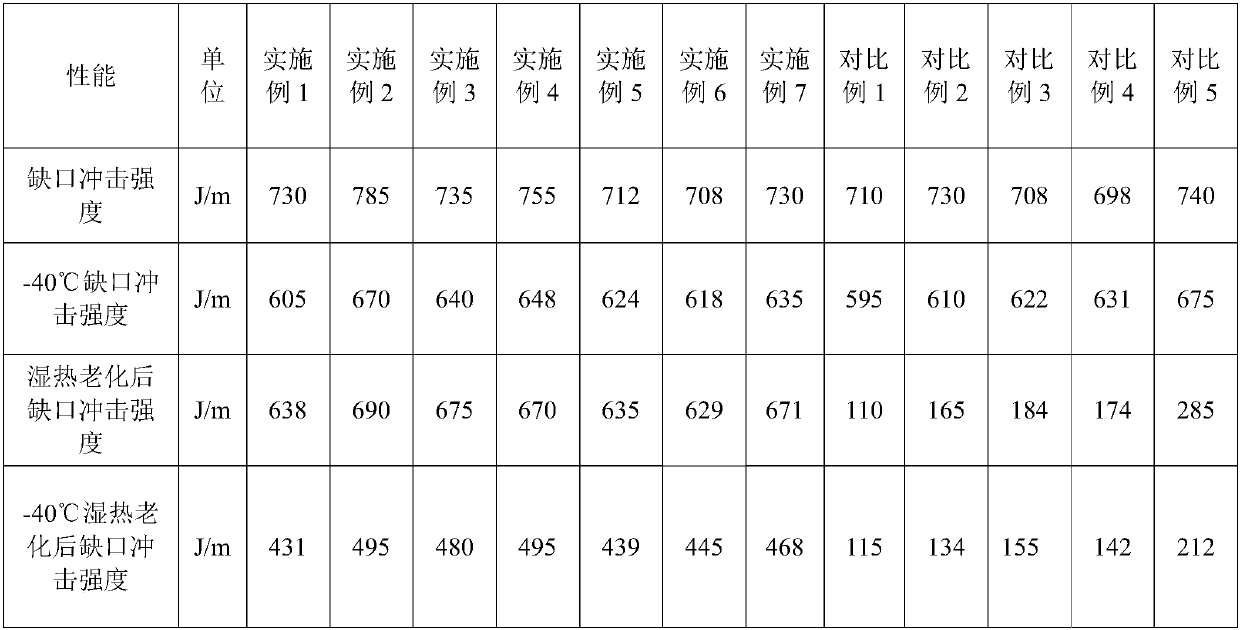

[0029] The present invention will be described in detail below in conjunction with the examples.

[0030] See Table 1 for the composition ratios of Examples 1-7 and Comparative Examples 1-5.

[0031] The PC resin adopted in Examples 1-7 and Comparative Examples 1-5 adopts Lotte Chemical PC 1070, and the melt index (300°C×1.2KG) is 7g / 10min;

[0032] The flame retardant that adopts in embodiment 1-7 and comparative example 1-5 is the BC-58 that U.S. Great Lakes Company produces;

[0033] The flame retardant synergist used in Examples 1-7 and Comparative Examples 1-5 is FCA-107 produced by U.S. Dow Corning;

[0034] The low-temperature toughening agent adopted in Examples 1-7 and Comparative Examples 1-5 is SX-005 produced by Mitsubishi Rayon in Japan;

[0035] The poly (bis (phenoxy) phosphazene) that adopts in embodiment 1-7 and comparative example 1-5 is the SPB-100 that Japan Otsuka Company produces;

[0036] The anti-dripping agent adopted in Examples 1-7 and Comparative...

Embodiment 8

[0057] The shell of the charging gun is made of low-temperature-resistant, moisture-resistant, heat-resistant, flame-retardant PC material, which is prepared from the following components and raw materials in parts by weight:

[0058] 100 parts of polycarbonate; 6 parts of flame retardant; 1 part of flame retardant synergist; 4 parts of anti-low temperature toughening agent; 1.5 parts of poly(bis(phenoxy)aphosphazene); 0.4 parts of anti-dripping agent ; 0.6 part of ultraviolet absorber; 0.5 part of antioxidant. Among them, the flame retardant used is brominated polycarbonate, the flame retardant synergist is a fluorosilicon polymer with a double hydroxyl structure, and the anti-low temperature toughening agent is a core-shell structure coated with silicon-acrylic acid type AS, and the silicon content is greater than 75wt%, the melt index of polycarbonate is 15g / 10min, the anti-dripping agent is coated PTFE, the ultraviolet absorber is 2-cyano-3'3-diphenyl acrylate pentaerythri...

Embodiment 9

[0063] The shell of the charging gun is made of low-temperature, heat-resistant, and flame-retardant PC material, which is prepared from the following components and parts by weight: 100 parts of polycarbonate; 4 parts of flame retardant; 0.5 parts of flame-retardant synergist; low-temperature toughening 3 parts of agent; 0.5 part of poly(di(phenoxy)aphosphazene); 0.2 part of anti-dripping agent; 0.3 part of ultraviolet absorber; 0.3 part of antioxidant, wherein, the flame retardant used is brominated poly Carbonate, the flame retardant synergist is a fluorosilicon polymer with a double hydroxyl structure, the anti-low temperature toughening agent is a core-shell structure coated with silicon-acrylic acid type AS, the silicon content is greater than 75wt%, and the melt index of polycarbonate is 5g / 10min, the anti-dripping agent is coated PTFE, the ultraviolet absorber is 2-cyano-3'3-diphenyl acrylate pentaerythritol ester, the antioxidant is antioxidant P-EPQ and antioxidant 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com