Doped yellow near infrared reflecting pigment and preparation method thereof

A reflective pigment and near-infrared technology, applied in chemical instruments and methods, inorganic chemistry, molybdenum compounds, etc., can solve problems that affect health, pollute the environment, cause cancer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method for the above-mentioned doped yellow near-infrared reflective pigment, comprising the following steps:

[0034] (1) dissolving bismuth nitrate and lanthanum nitrate in acetic acid solution and mixing to obtain A solution;

[0035] (2) Sodium vanadate and sodium molybdate are dissolved in water to obtain B solution;

[0036] (3) Mixing the A solution and the B solution, adding urea and a surfactant to carry out a hydrothermal reaction to obtain a doped yellow near-infrared reflective pigment;

[0037] The steps (1) and (2) are not limited by time sequence.

[0038] In the present invention, bismuth nitrate and lanthanum nitrate are dissolved in acetic acid solution to obtain A solution. In the present invention, the acetic acid solution is preferably glacial acetic acid, and the mass ratio of the total mass of bismuth nitrate and lanthanum nitrate to the acetic acid solution is preferably 1:25-30, more preferably 1:26-28. In...

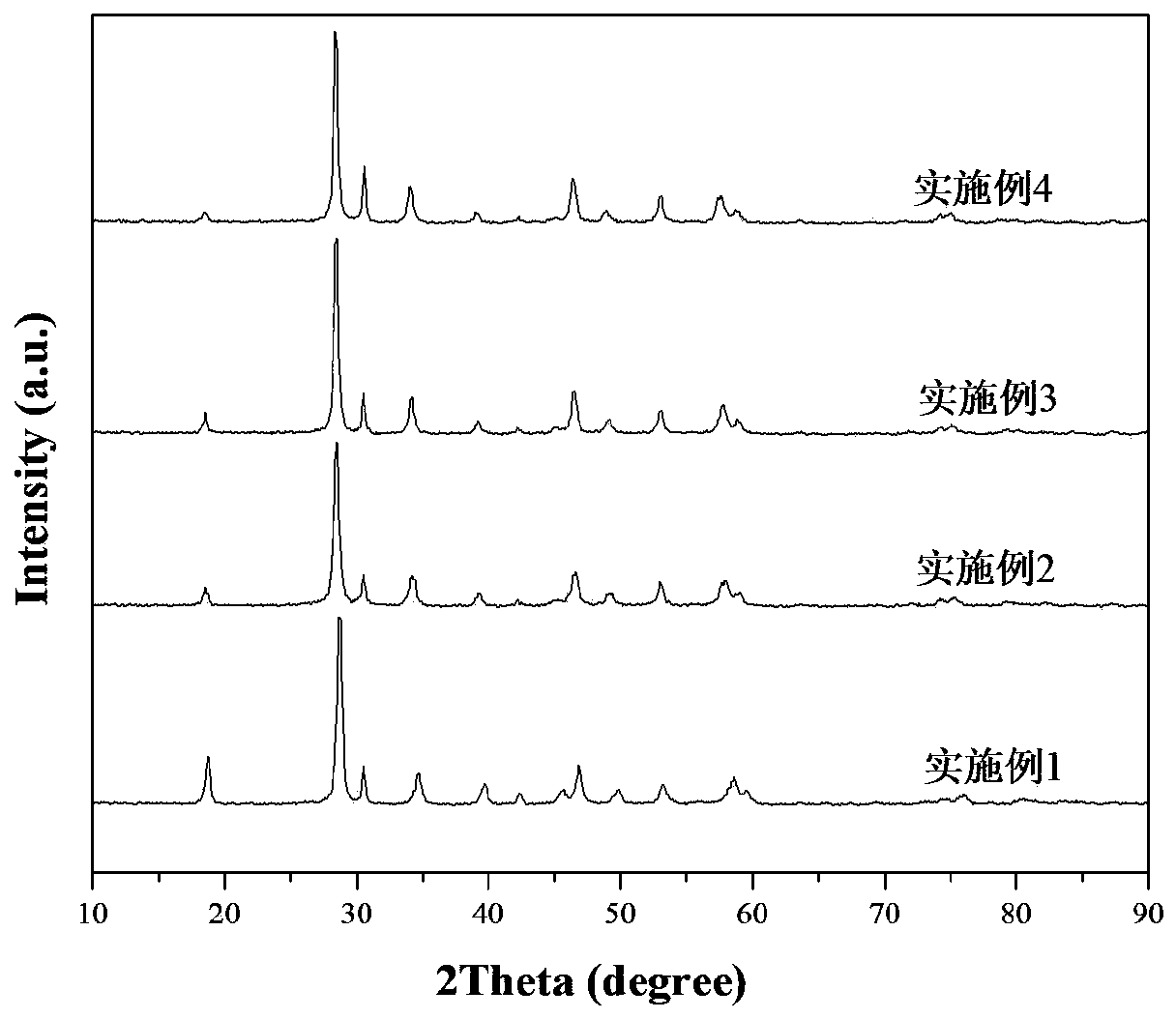

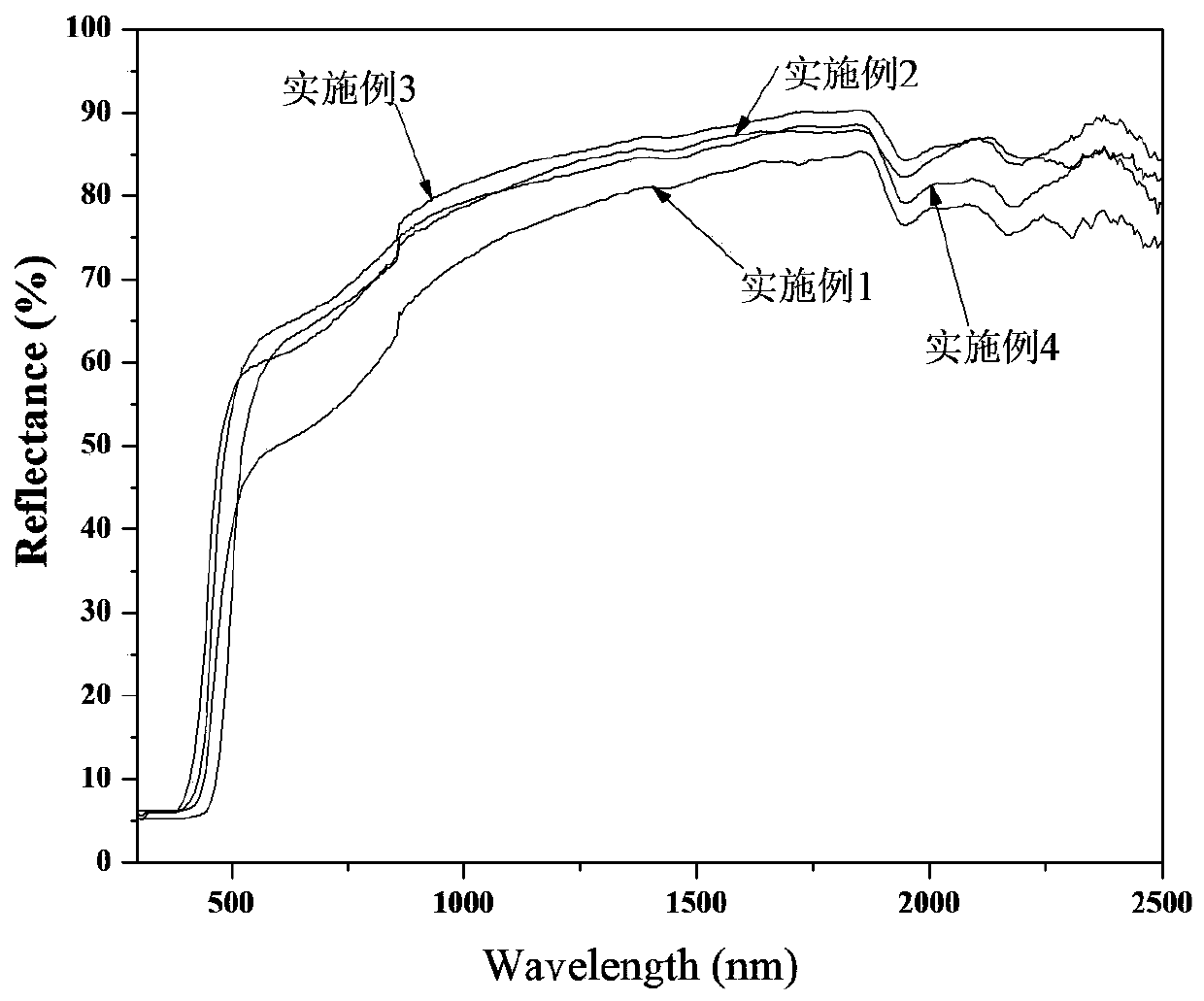

Embodiment 1

[0048] Prepare Bi(NO 3 ) 3 ·5H 2 O, La(NO 3 ) 3 ·6H 2 O, Na 3 VO 4 and Na 2 MoO 4 2H 2 O raw material, wherein, Bi accounts for 45.0% of the total molar weight of metal elements, La accounts for 2.5% of the total molar weight of metal elements, V accounts for 45.0% of the total molar weight of metal elements, Mo accounts for 5.0% of the total molar weight of metal elements, Na Accounting for 2.5% of the total molar weight of metal elements, the chemical composition of the pigment is expressed as: Bi 0.9 (Na 0.5 La 0.5 ) 0.1 V 0.9 Mo 0.1 o 4 .

[0049] The preparation steps are as follows:

[0050] (1) Bi(NO 3 ) 3 ·5H 2 O, La(NO 3 ) 3 ·6H 2 O was dissolved in glacial acetic acid, the mass ratio of glacial acetic acid to nitrate was controlled to be 25:1, heated in a water bath at 90°C until all the salts were completely dissolved, and A solution was obtained;

[0051] (2) Na 3 VO 4 and Na 2 MoO 4 2H 2 O is dissolved in distilled water to obtain B so...

Embodiment 2

[0057] Prepare Bi(NO 3 ) 3 ·5H 2 O, La(NO 3 ) 3 ·6H 2 O, Na 3 VO 4 and Na 2 MoO 4 2H 2 O raw material, wherein, Bi accounts for 35.0% of the total molar weight of metal elements, La accounts for 7.5% of the total molar weight of metal elements, V accounts for 35.0% of the total molar weight of metal elements, Mo accounts for 15.0% of the total molar weight of metal elements, Na Accounting for 7.5% of the total molar weight of metal elements, the chemical composition of the pigment is expressed as: Bi 0.9 (Na 0.5 La 0.5 ) 0.1 V 0.9 Mo 0.1 o 4 .

[0058] The preparation steps are as follows:

[0059] (1) Bi(NO 3 ) 3 ·5H 2 O, La(NO 3 ) 3 ·6H 2 Dissolve O in glacial acetic acid, control the mass ratio of glacial acetic acid to nitrate to 30:1, heat in a water bath at 90°C until all the salts are completely dissolved, and obtain A solution;

[0060] (2) Na 3 VO 4 and Na 2 MoO 4 2H 2 O is dissolved in distilled water to obtain B solution;

[0061] (3) M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com