High-light-reflection phase-change heat storage coating for textiles and preparation method of high-light-reflection phase-change heat storage coating

A phase change heat storage and light reflection technology, applied in the field of textiles, can solve the problem that the coating cannot take into account the temperature adjustment performance, high light reflection performance and stain resistance, reduce VOC content, etc. Contamination performance, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

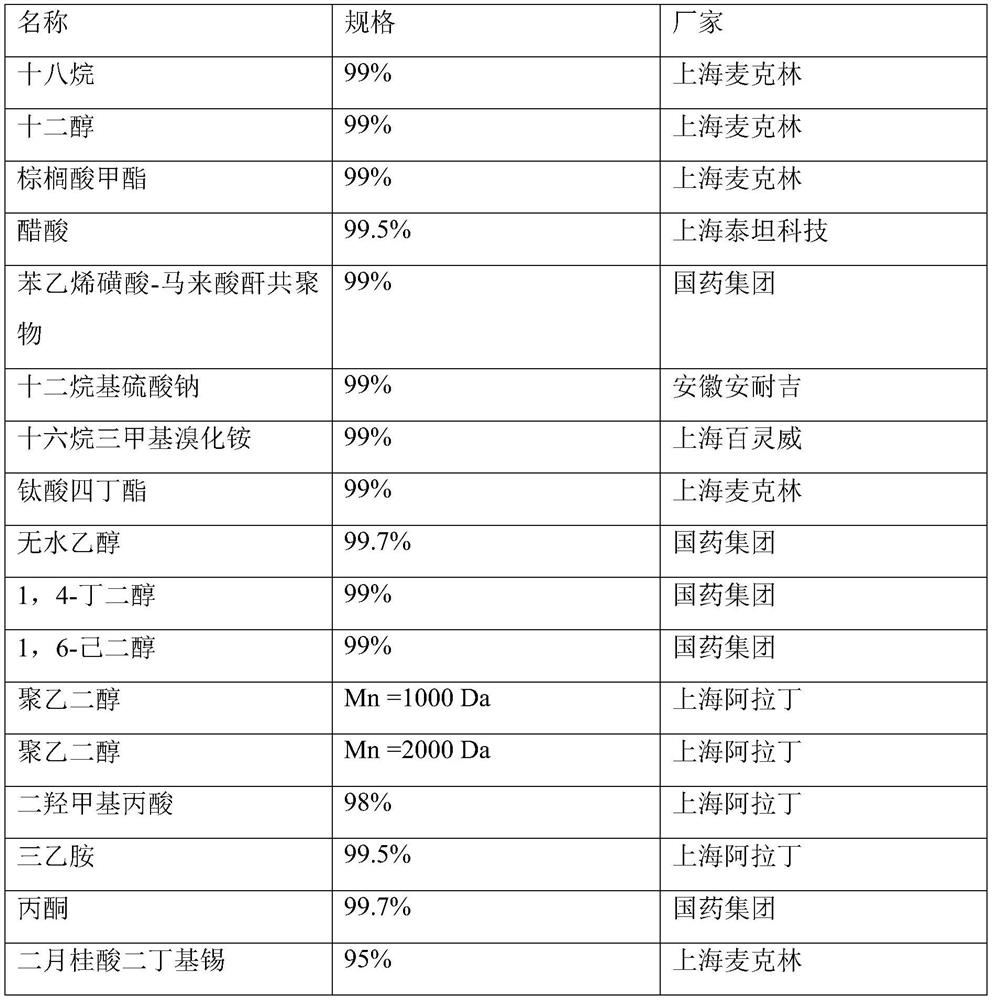

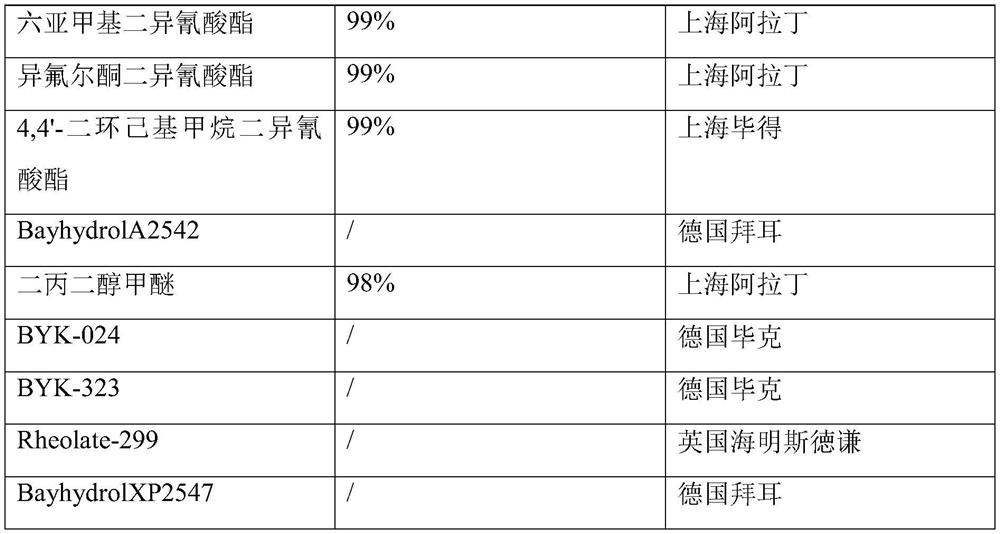

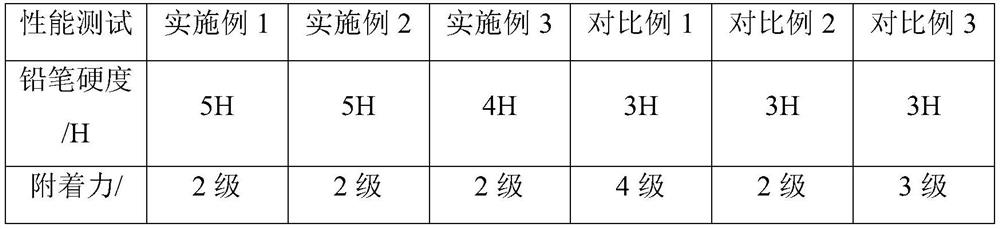

Embodiment 1

[0074] Weigh 25g of octadecane, dissolve it in 300ml of water, add 3g of sodium dodecyl sulfate, emulsification at a high speed of 500r / min to form a microemulsion, and keep the temperature at 50°C. Add acetic acid to adjust the pH to 3, slowly add a mixed solution of 20 g of tetrabutyl titanate and 60 ml of ethanol, react for 10 hours, then filter, wash, and dry at 60° C. for 24 hours to obtain phase-change microcapsules. Phase change microcapsules, styrene sulfonic acid-maleic anhydride copolymer and deionized water were mixed in a mass ratio of 0.5:0.2:100, then ultrasonically treated for 0.5 h, centrifuged, washed, and dried in a vacuum oven at 60 °C for 24 h. The modified phase change microcapsules were obtained.

[0075] 1000Da polyethylene glycol and dimethylolpropionic acid were dewatered in a vacuum oven at 110°C for 4 hours, and hexamethylene diisocyanate was dewatered by molecular sieves for 4 hours. 74g hexamethylene diisocyanate, 220g poly Ethylene glycol and 120...

Embodiment 2

[0082] Weigh 27g of dodecanol, dissolve it in 300ml of water, add 1g of cetyltrimethylammonium bromide, emulsification at a high speed of 800r / min to form a microemulsion, and keep the temperature at 70°C. Add acetic acid to adjust the pH to 4, slowly add a mixed solution of 27g tetrabutyl titanate and 80ml ethanol, react for 15h, then filter, wash, dry, and dry at 70°C for 20h to obtain phase change microcapsules. Phase change microcapsules, styrene sulfonic acid-maleic anhydride copolymer and deionized water were mixed in a mass ratio of 1:0.4:130, then ultrasonically treated for 1.5 h, centrifuged, washed, and dried in a vacuum oven at 70 °C for 20 h. The modified phase change microcapsules were obtained.

[0083] Dewater 1000Da polyethylene glycol and dimethylolpropionic acid in a vacuum oven at 110°C for 4 hours, isophorone diisocyanate is dewatered with molecular sieves for 4 hours, and 90g isophorone diisocyanate, 200g polyethylene glycol, 120ml of acetone solvent was ...

Embodiment 3

[0090] Weigh 20g of octadecane and 15g of methyl palmitate, mix them evenly, dissolve in 400ml of water, add 5g of sodium dodecyl sulfate, emulsification at 1200r / min at high speed to form a microemulsion, and keep the temperature at 50°C. Add acetic acid to adjust the pH to 2, slowly add a mixed solution of 35 g of tetrabutyl titanate and 80 ml of ethanol, react for 24 hours, then filter, wash, and dry at 80°C for 12 hours to obtain phase-change microcapsules. Phase change microcapsules, styrene sulfonic acid-maleic anhydride copolymer and deionized water were mixed in a mass ratio of 2:0.6:150, then ultrasonically treated for 2 hours, centrifuged, washed, and dried in a vacuum oven at 80 °C for 12 hours to obtain Modified phase change microcapsules.

[0091] 2000Da polyethylene glycol and dimethylolpropionic acid were dewatered in a vacuum oven at 110°C for 4h, 4,4'-dicyclohexylmethane diisocyanate was dewatered with molecular sieves for 4h, and 52g of 4,4'-dicyclohexylmetha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com