Metal ion doped bismuth vanadate yellow pigment as well as preparation method and application thereof

A metal ion and yellow pigment technology, applied in the field of inorganic pigments, can solve the problem of limited near-infrared reflectivity of bismuth vanadate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention provides the preparation method of metal ion-doped bismuth vanadate yellow pigment described in the above technical scheme, comprising:

[0024] Bi 2 o 3 、Gd 2 o 3 , Li 2 CO 3 、MoO 3 and V 2 o 5 Calcination is carried out after mixing to obtain metal ion-doped bismuth vanadate yellow pigment.

[0025] Unless otherwise specified, the present invention has no special limitation on the source of each component, and commercially available products well known to those skilled in the art can be used.

[0026] In the present invention, the Bi 2 o 3 The mass content in the raw material is preferably 40-67%, more preferably 45-60%, more preferably 50-55%. In the present invention, the Bi 2 o 3 Used to provide Bi element.

[0027] In the present invention, the Gd 2 o 3 The mass content in the raw material is preferably 2.5-16%, more preferably 5-13%, more preferably 8-10%. The present invention will Gd 2 o 3 The mass content of is limited ...

Embodiment 1

[0042] Take by weighing reaction raw material according to mass content: Bi 2 o 3 66.18%, Gd 2 o 3 2.86%, Li 2 CO 3 0.58%, MoO 3 4.54% and V 2 o 5 25.84% 100g in total, put it into a planetary ball mill, use acetone as solvent, and ball-to-material ratio is 4:1 ball mill for 2 hours, put the ground powder into a high-temperature furnace for calcination at 800°C for 5 hours, cool naturally to room temperature and then put it into the planetary ball mill In a ball mill, acetone was used as a solvent and the ball-to-material ratio was 4:1 for ball milling for 4 hours to obtain metal ion-doped bismuth vanadate yellow pigment.

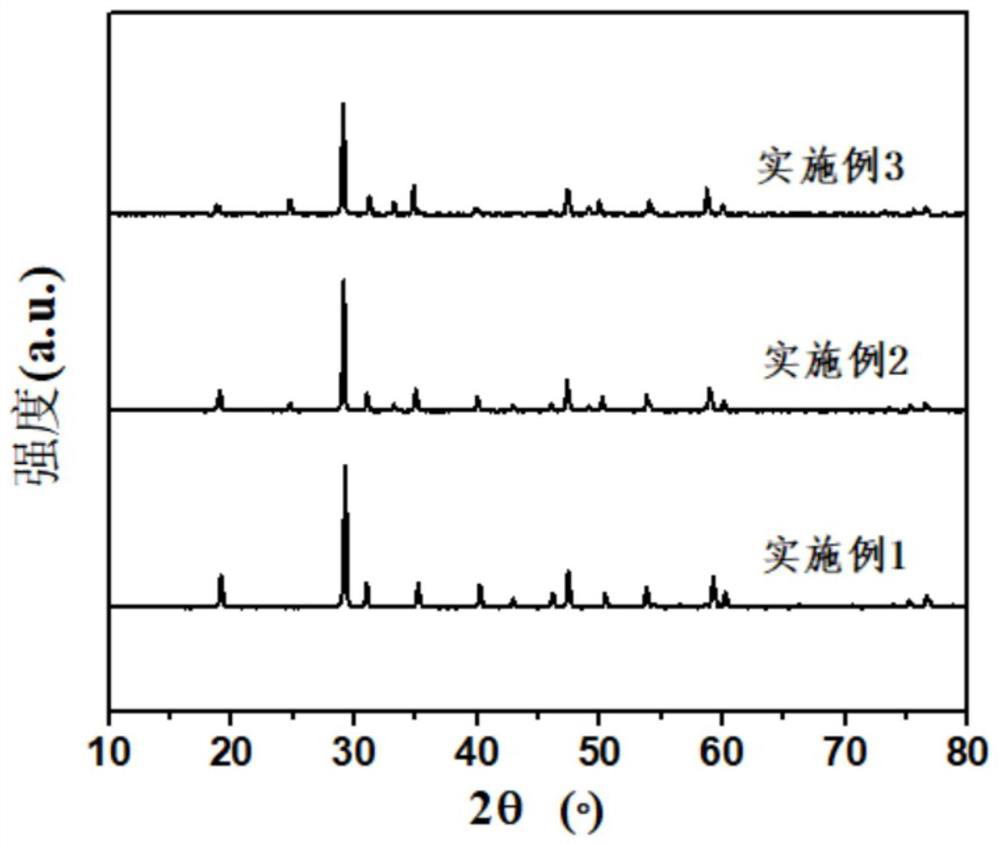

[0043] The crystal structure of the obtained pigment was characterized by X-ray powder diffraction method, and the results were as follows: figure 1 As shown, the obtained spectrum is compared with the standard card, and the result shows that the obtained pigment is a crystal of scheelite structure.

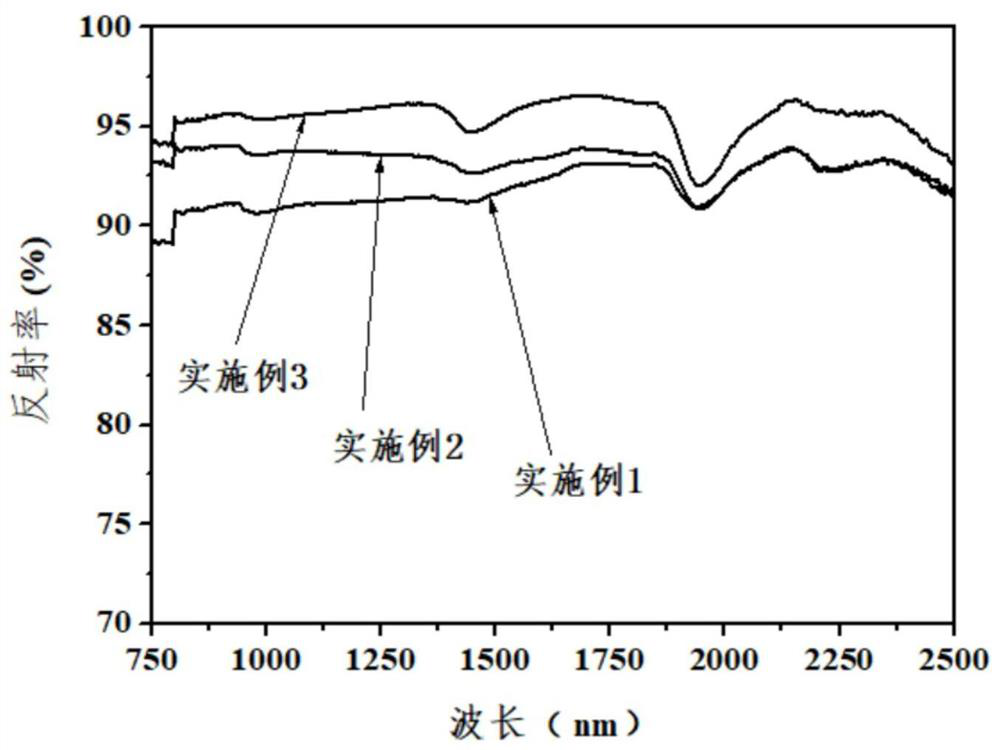

[0044] Use UV-vis-NIR spectrophotometer to meas...

Embodiment 2

[0046] Take by weighing reaction raw material according to mass content: Bi 2 o 3 53.88%, Gd 2 o 3 8.98%, Li 2 CO 3 1.83%, MoO 3 14.27% and V 2 o 5 21.04% 100g in total, put it into a planetary ball mill, use acetone as a solvent, and ball-to-material ratio is 4:1 ball mill for 2 hours, put the ground powder into a high-temperature furnace for calcination at 700°C for 6 hours, cool naturally to room temperature and then put it into the planetary ball mill In a ball mill, acetone was used as a solvent, and the ball-to-material ratio was 4:1 for ball milling for 5 hours to obtain metal ion-doped bismuth vanadate yellow pigment.

[0047] The crystal structure of the obtained pigment was characterized by X-ray powder diffraction method, and the results were as follows: figure 1 As shown, the obtained spectrum is compared with the standard card, and the result shows that the obtained pigment is a crystal of scheelite structure.

[0048] Use UV-vis-NIR spectrophotometer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com