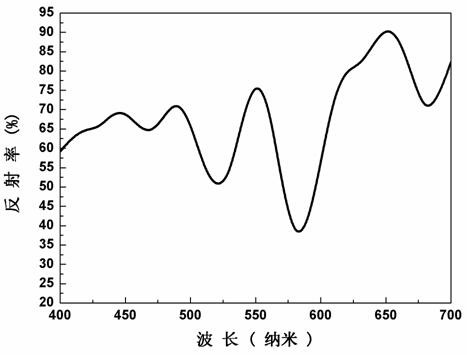

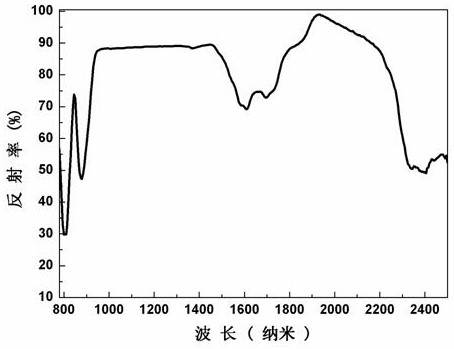

A near-infrared high-reflectivity functional ceramic pigment and preparation method thereof

A high-reflectivity, functional ceramic technology, applied in chemical instruments and methods, preparation/processing of rare earth metal compounds, fibrous fillers, etc., can solve problems such as aging, staining, fading and falling off, and achieve simple process, near High infrared reflectivity, which is conducive to the effect of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of near-infrared high-reflectivity functional ceramic pigments specifically includes the following process steps:

[0033] (1) Prepare 180 ml of water / alcohol solution ( V 水 : V 乙醇 = 1 : 5), add 10 ml of glacial acetic acid, mix well, then add 0.1 mole of tetraethyl orthosilicate, stir for 8 minutes, then add 0.35 mole of citric acid as a chelating agent, and use magnetic stirring at the same time to form a transparent sol;

[0034] (2) According to the chemical composition Nd 2 Ti 0.3 Si 1.7 o 7 Weigh butyl titanate and neodymium nitrate, add butyl titanate directly to the transparent sol in step (1), and at the same time fully dissolve neodymium nitrate in 50 ml of deionized water, add it to the transparent sol, and stir for 1 hour . The sol was then moved to a water bath at 90° C. and stirred for 1 hour, and then stirred continuously in an oil bath at 130° C. for 2 hours to obtain a xerogel.

[0035] (3) The dry gel was heat-treated at 1200°...

Embodiment 2

[0039] The preparation of near-infrared high-reflectivity functional ceramic pigments specifically includes the following process steps:

[0040] (1) Prepare 180 ml of water / alcohol solution ( V 水 : V 乙醇 = 1 : 3), add 10 ml of glacial acetic acid, mix well, then add 0.1 mole of sodium silicate, stir for 5 minutes, then add 0.5 mole of citric acid as a chelating agent, and use magnetic stirring at the same time to form a transparent sol;

[0041] (2) According to the chemical composition Nd 2 Ti 0.05 Si 1.95 o 7 Weigh titanium tetrachloride and neodymium sulfate, add titanium tetrachloride directly into the transparent sol in step (1), at the same time fully dissolve neodymium sulfate in 50 ml of deionized water, add it to the transparent sol, and stir for 2 hours . The sol was then moved to a water bath at 80° C. and stirred for 1 hour, and then stirred continuously in an oil bath at 120° C. for 1.5 hours to obtain a xerogel.

[0042] (3) The dry gel was heat-treated...

Embodiment 3

[0046] The preparation of near-infrared high-reflectivity functional ceramic pigments specifically includes the following process steps:

[0047] (1) Prepare 180 ml of water / alcohol solution ( V 水 : V 乙醇 = 1 : 4), add 15 ml of glacial acetic acid, mix well, then add 0.1 mol of sodium silicate, stir for 5 minutes, then add 0.4 mol of citric acid as a chelating agent, and use magnetic stirring at the same time to form a transparent sol;

[0048] (2) According to the chemical composition Nd 2 Ti 0.75 Si 1.25 o 7 Weigh titanium tetrachloride and neodymium chloride, add titanium tetrachloride directly to the transparent sol in step (1), and at the same time fully dissolve neodymium chloride in 50 ml of deionized water, add it to the transparent sol, and stir thoroughly 1 hour. Then the sol was moved to a water bath at 85° C. and stirred for 1 hour, and then stirred continuously in an oil bath at 140° C. for 1 hour to obtain a xerogel.

[0049] (3) The dry gel was heat-tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com